Lens for digital camera and its producing method

A technology for digital cameras and manufacturing methods, which is applied in the field of optical lenses and can solve the problems of complex assembly and difficulty in reducing the size of lens modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The lens for a digital camera of the present invention is used for a small digital camera, or portable electronic devices such as a mobile phone with a digital camera, and a PDA.

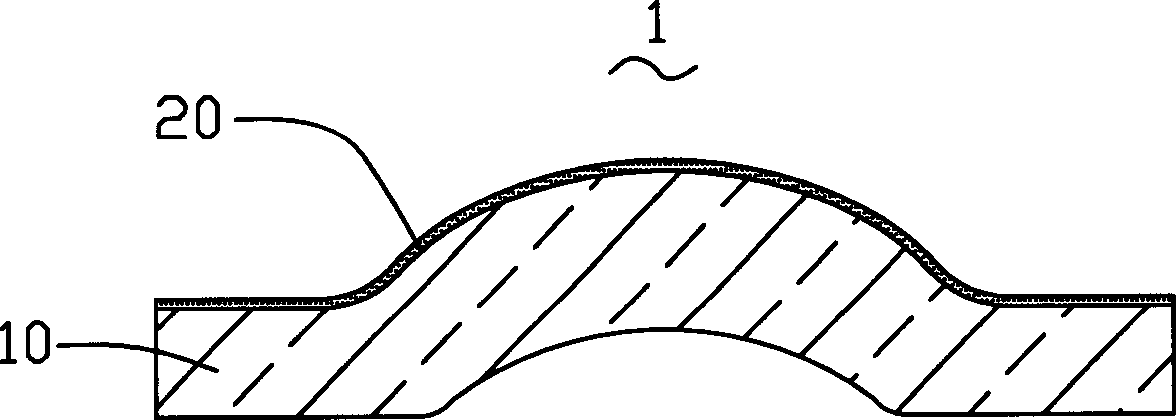

[0023] Please refer to figure 1 As shown, the lens 1 for a digital camera of the present invention includes a lens base 10 and a filter film 20 . Wherein the lens base 10 is an ordinary spherical lens or aspheric lens for digital cameras, and its material is transparent bodies such as glass or plastics, and the filter film 20 is attached to the lens base 10 by hot pressing, which can be an anti-reflection film, Infrared cut filter film, etc.

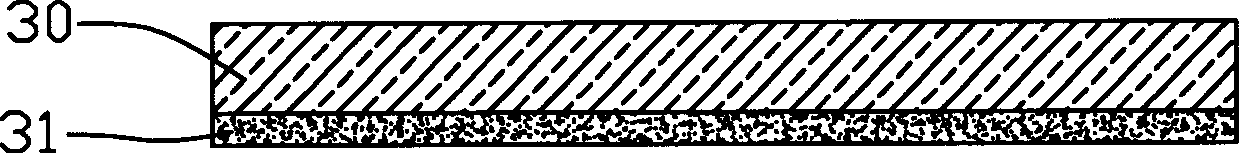

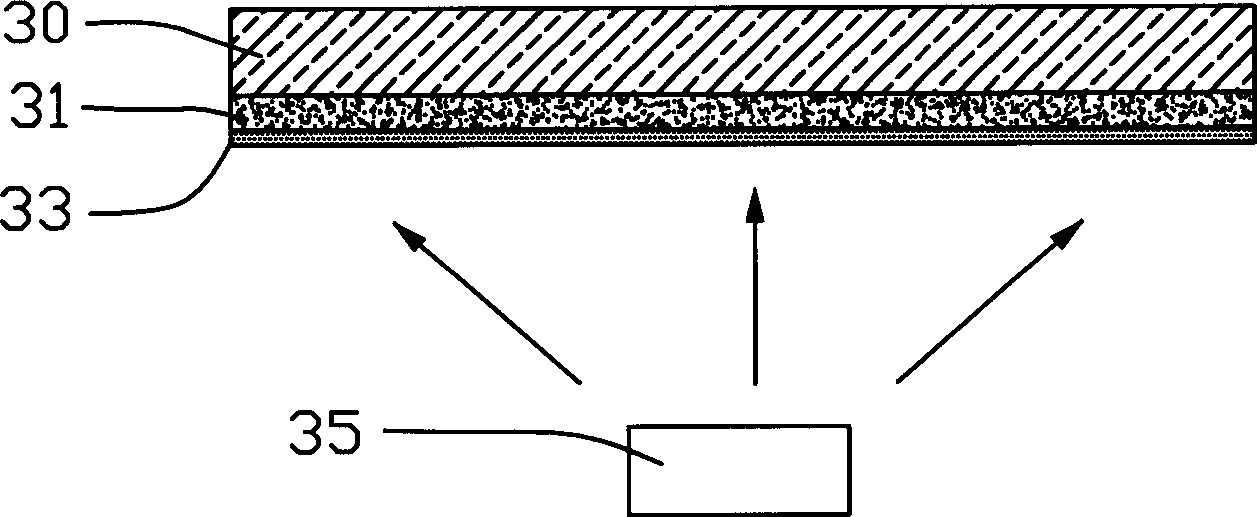

[0024] Please also refer to figure 2 , image 3 , Figure 4 and Figure 5 As shown, the manufacturing method of the digital camera lens 1 comprises the following steps:

[0025] Coating a uniform water-soluble UV-curable adhesive 31 on the glass substrate 30;

[0026] Place the glass substrate 30 coated with UV-curable glue 31 in a vacuum evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com