Transformer

A technology of transformers and insulating tapes, applied in transformer/inductor components, transformer/inductor coils/windings/connections, coils, etc., can solve the problems of large transformer size, increased production cost, long time, etc., to achieve small The effect of transformer size, increased production cost, and increased occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

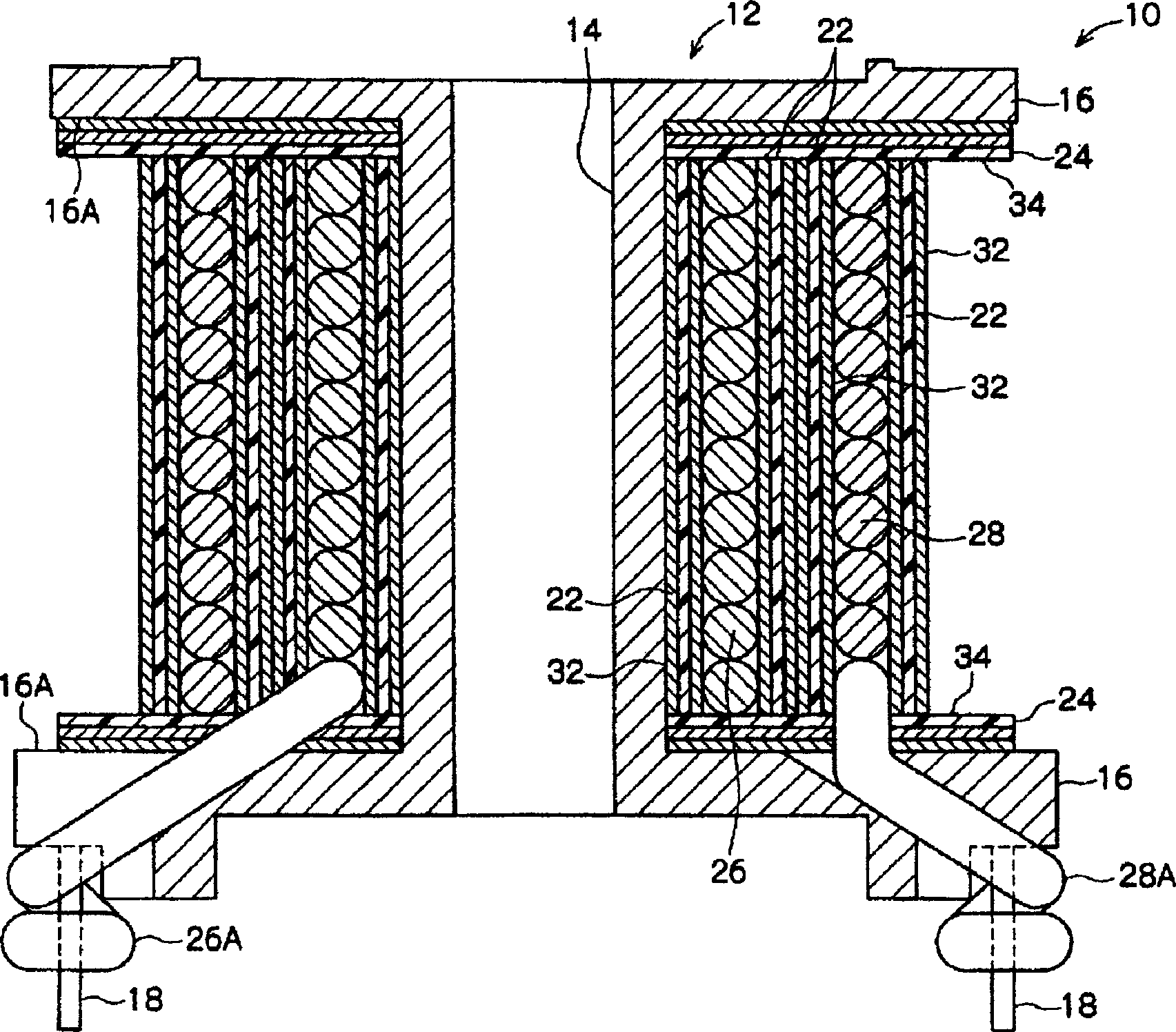

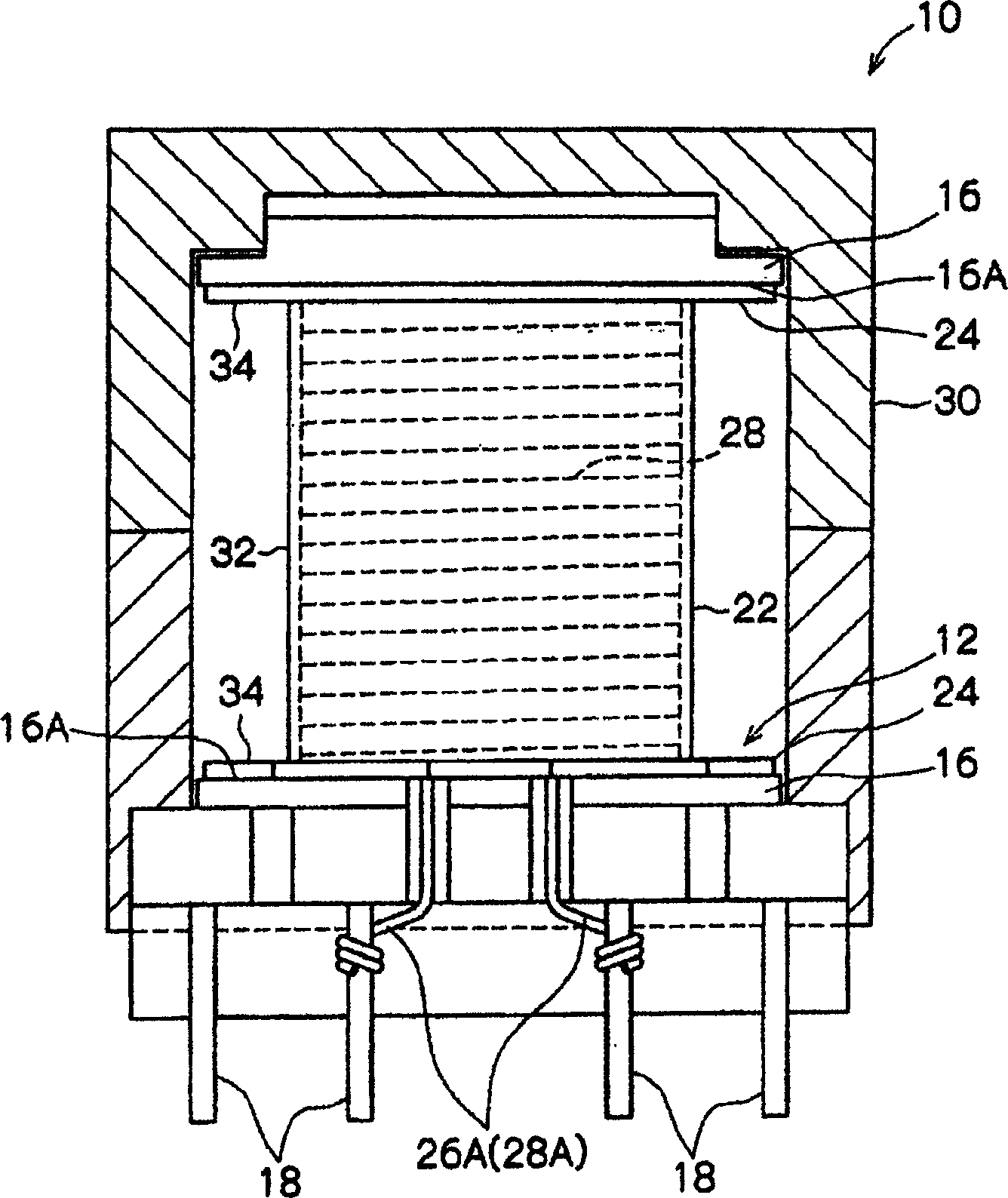

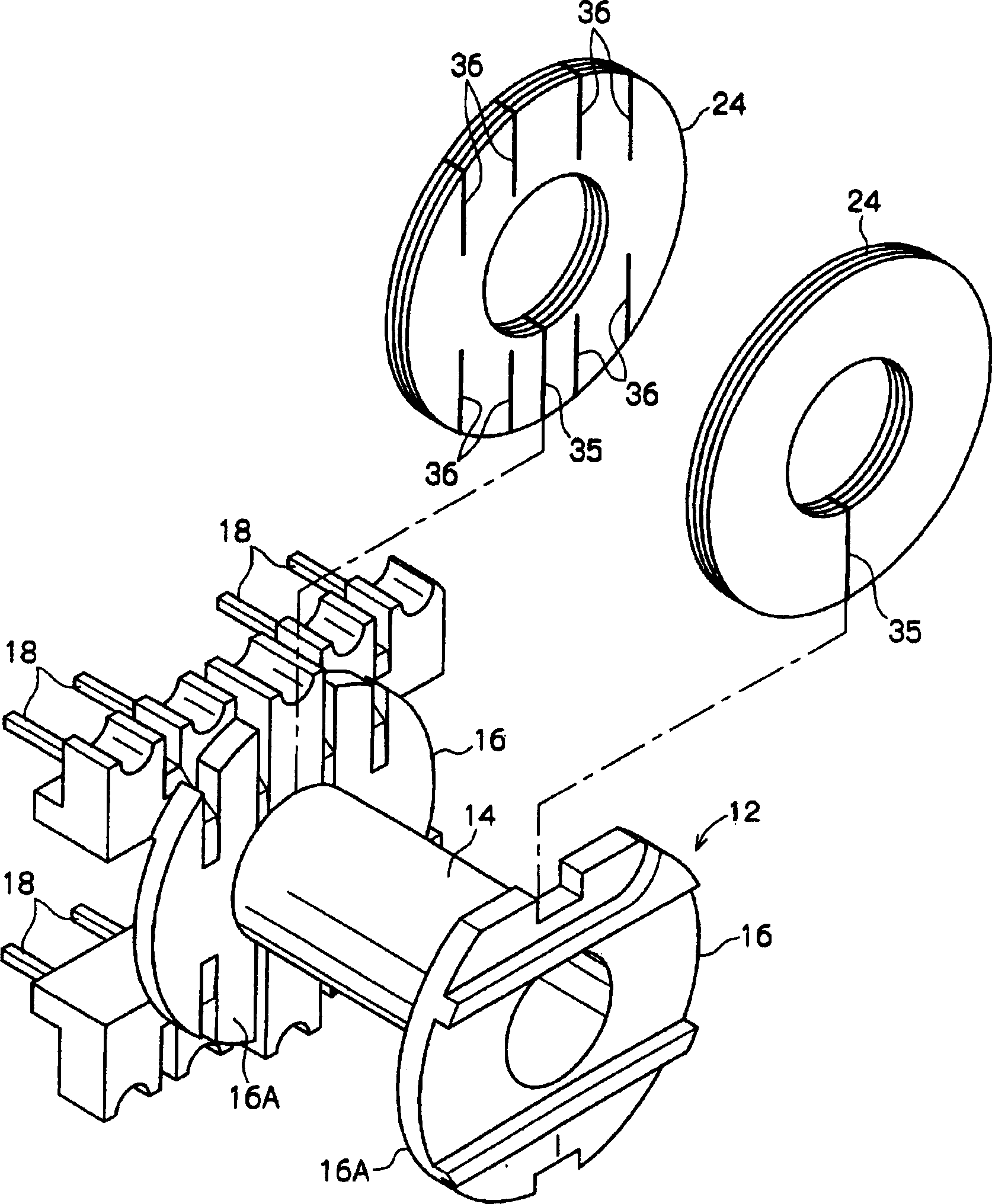

[0030] below, in Figure 1 to Figure 5 Embodiments of the transformer of the present invention are shown in and described with reference to these drawings. Such as Figure 1 to Figure 3 As shown, the bobbin 12 of the transformer 10 of the present embodiment is provided with a cylindrical bobbin 14 and a pair of flanges 16 formed at both ends of the bobbin 14 . One of the flanges 16 is provided with a plurality of terminals 18 , and the base ends of the terminals 18 are embedded in the flange 16 .

[0031] Such as figure 1 As shown, on the outer periphery of the bobbin 14, there is provided an insulating layer 32 formed by thermally curing the interlayer insulating prepreg tape constituting the first insulating tape. The primary coil 26 is wound on the outer circumference side of the insulating layer 32 , and the secondary coil 28 is wound on the outer circumference of the primary coil 26 . Further, lead wires 26A, 28A at both ends of these primary coils and secondary coils...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com