Chimney type organic garbage fertilizer-making machine

A technology of organic waste and organic fertilizer, applied in the direction of organic fertilizer, climate change adaptation, etc., can solve the problems of high operating cost, unfavorable in-situ fertilization of organic waste, large land occupation, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

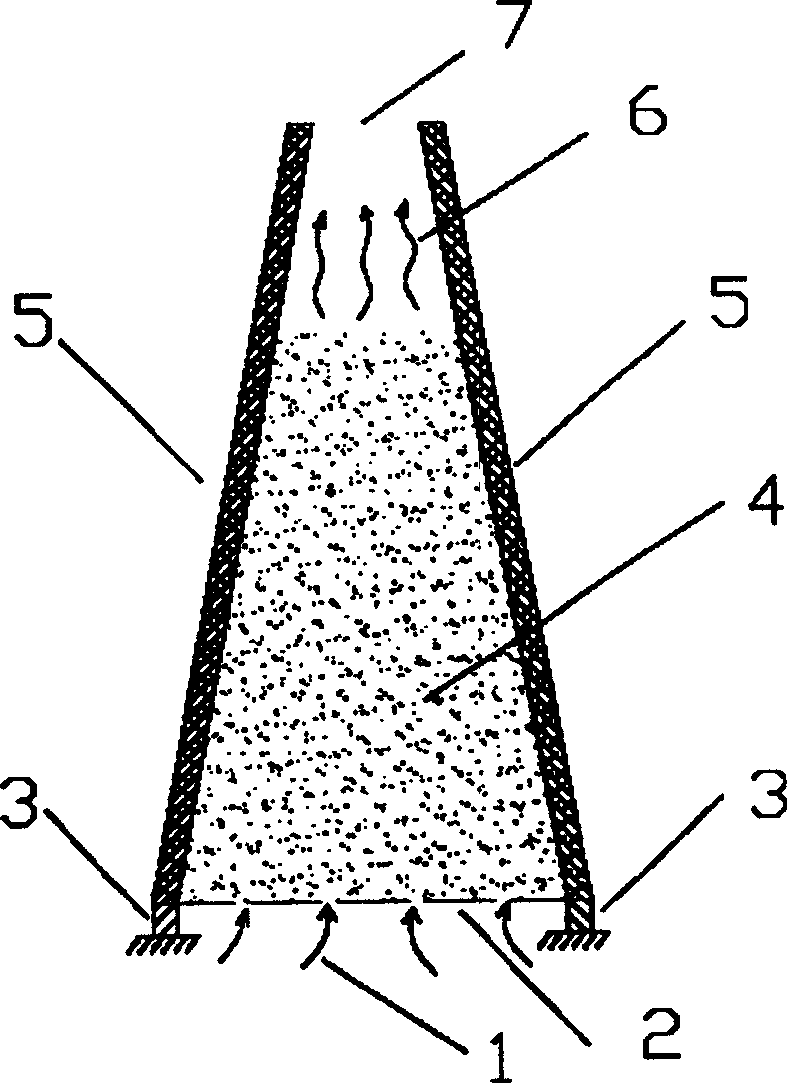

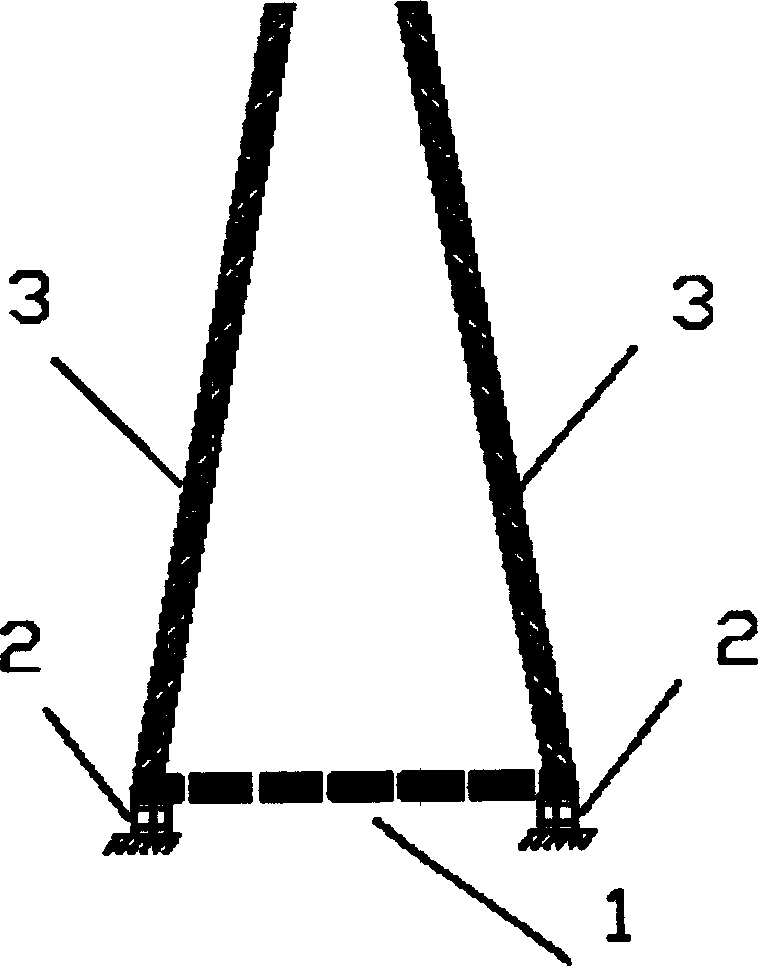

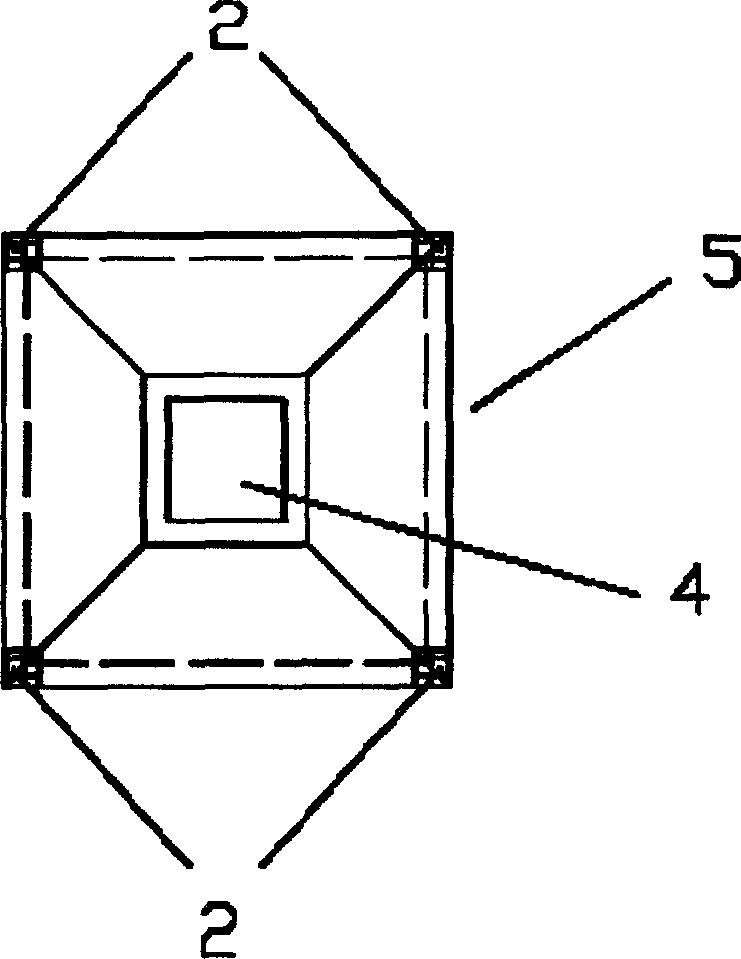

[0014] FIG. 2 is a plan view of the device of Embodiment 1, FIG. 3 is a vertical cross-sectional view of the device of Embodiment 1, and FIG. 4 is a schematic diagram of a perforated plate of Embodiment 1. The device is composed of a chimney-shaped main body 3, a perforated plate 1 and a bracket 2, and the chimney-shaped main body 3 is a regular quadrangular pyramid with a large lower bottom surface 5 and a small upper bottom surface 4. The chimney-shaped main body 3 is made of polyvinyl chloride, which is wrapped with rock wool for thermal insulation; the perforated plate 1 and the bracket 2 are both made of polyvinyl chloride. During installation, the perforated plate 1 and the bracket 2 are fixed together first, and then the chimney-shaped main body 3 is sheathed outside the perforated plate and its weight is supported by the bracket. When in use, the organic waste is put into the opening of the chimney-shaped main body 3, and after a period of natural fermentation treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com