Apparatus for forming ion-exchanged water and method for regenerating ion exchange resin therein

An ion-exchanged water and generation device technology, applied in ion-exchange regeneration, ion-exchange treatment devices, ion-exchanged water/sewage treatment, etc., can solve the problems of reducing the amount of regenerated water, reducing the cost of ion-exchange resins, etc. Water usage and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0032]

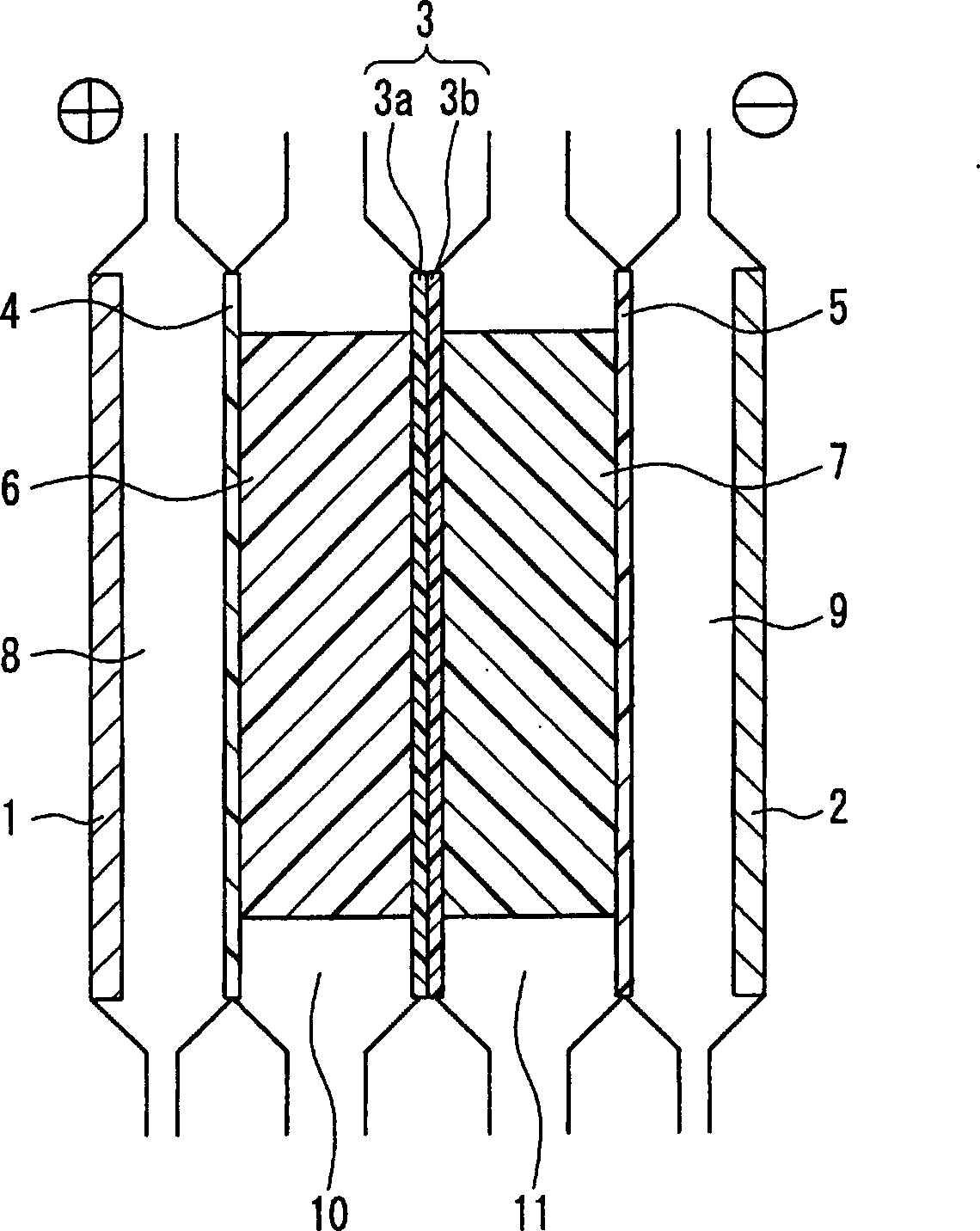

[0033] figure 1 It is a cross-sectional schematic diagram of an example of the ion-exchanged water production|generation apparatus of this invention. like figure 1The ion-exchanged water generator shown is provided with a pair of electrodes consisting of an anode 1 and a cathode 2 for electrolysis, and an anion-exchange resin separated by a bipolar membrane 3 to which an anion-exchange membrane 3a and a cation 3b are bonded. The chamber 10 and the cation exchange resin chamber 11; the anion exchange resin chamber 10 is filled with an anion exchange resin 6, and the anion exchange resin chamber 10 is arranged on the side of the anode 1; the cation exchange resin chamber 11 is filled with the cation exchange resin 7, the The cation exchange resin chamber 11 is arranged on the anode 2 side. In the bipolar membrane 3 described above, the anion exchange membrane 3a is arranged on the anode 1 side, and the cation exchange membrane 3b is arranged on the cathode 2 side. ...

Example

[0045]

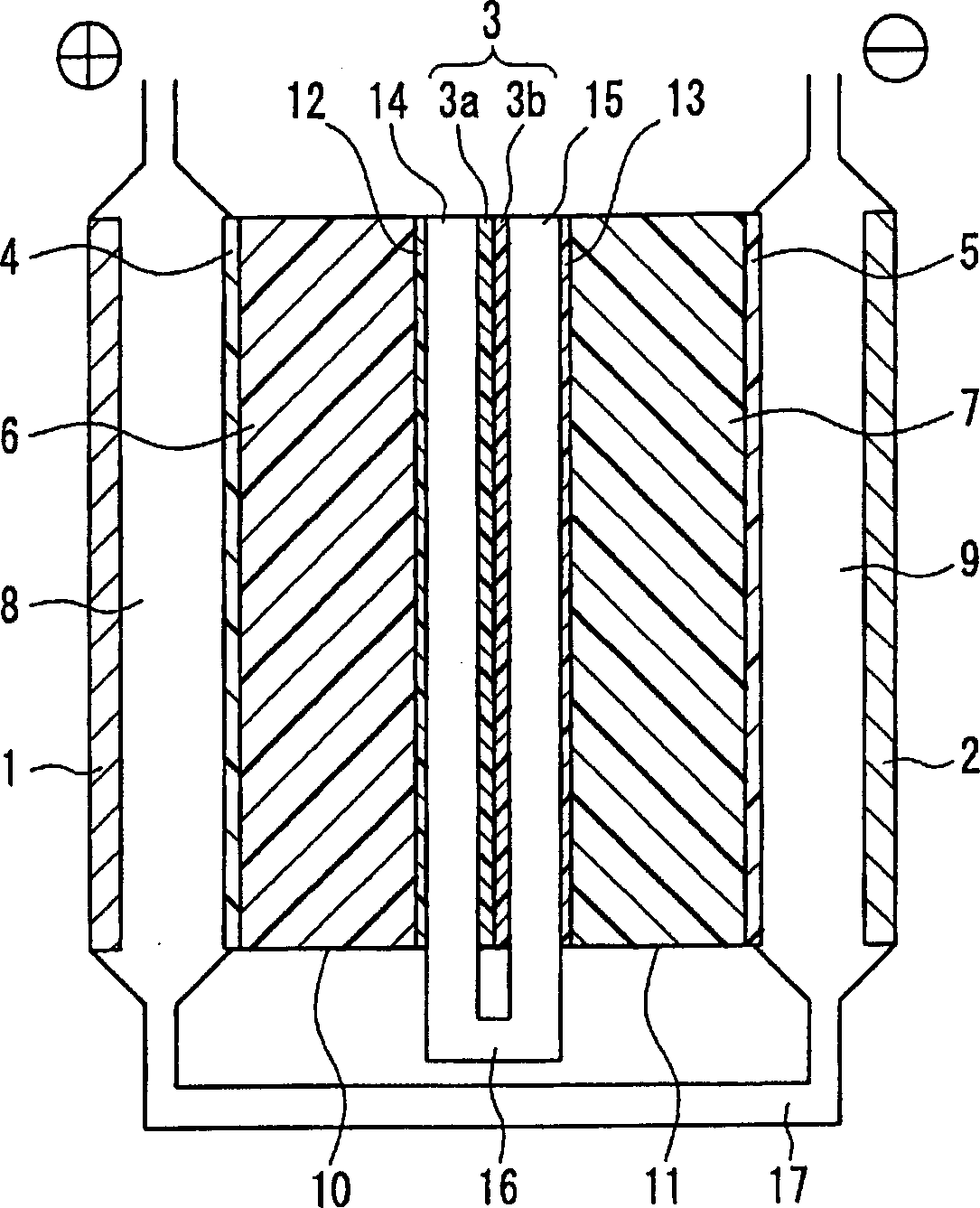

[0046] figure 2 It is a schematic cross-sectional view of another example of the ion-exchanged water production apparatus of the present invention. exist figure 2 , to the same as the above figure 1 Components with common functions are given common symbols to avoid repeated descriptions. figure 2 The ion-exchanged water generator shown is provided with: a pair of electrodes consisting of an anode 1 and a cathode 2 for electrolysis; a bipolar membrane 3 to which an anion-exchange membrane 3a and a cation-exchange membrane 3b are bonded; A cation exchange resin chamber 11 filled with a cation exchange resin 7; an anion exchange resin chamber 10 filled with an anion exchange resin 6 in a space separated by a membrane; and an anode chamber 8 and a cathode chamber 9.

[0047] The anode chamber 8 is arranged outside the anion exchange resin chamber 10 and is separated by the anode 1 and the membrane 4 of the anion exchange resin chamber 10; the cathode chamber 9 is ...

Example

[0055]

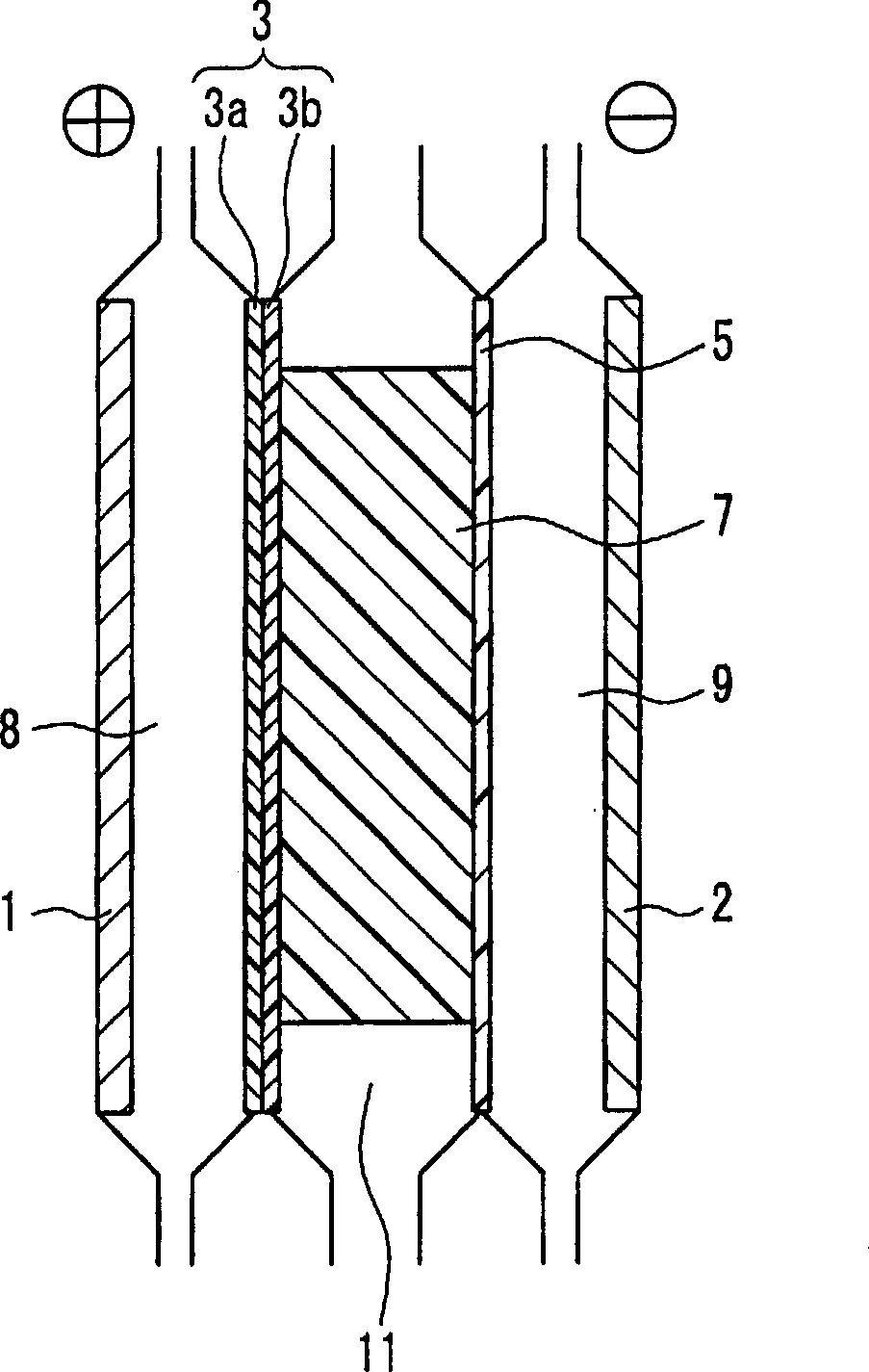

[0056] image 3 It is a schematic cross-sectional view of another example of the ion-exchanged water production apparatus of the present invention. exist image 3 , to the same as the above figure 1 Components with common functions are given common symbols to avoid repeated descriptions. image 3 The ion-exchanged water generator shown is provided with a pair of electrodes consisting of an anode 1 and a cathode 2 for electrolysis, and separated by a bipolar membrane 3 and a separator 5 to which an anion-exchange membrane 3a and a cation-exchange membrane 3b are bonded. The cation exchange resin chamber 11; and the anode chamber 8 separated by the bipolar membrane 3 and the anode 1, and the cathode chamber 9 separated by the diaphragm 5 and the cathode 2 are provided outside the cation exchange resin chamber 11. exist image 3 In the ion-exchanged water generating apparatus shown, the bipolar membrane 3 is also arranged, the anion-exchange membrane 3a is arranged...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap