Mounting protection and method of mounting a mounting protection and method of manufacturing a mounting protection

A fixed device and matching technology, applied in manufacturing tools, assembly machines, vibration suppression adjustment, etc., can solve problems such as unreliable processes, and achieve the effect of ensuring operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

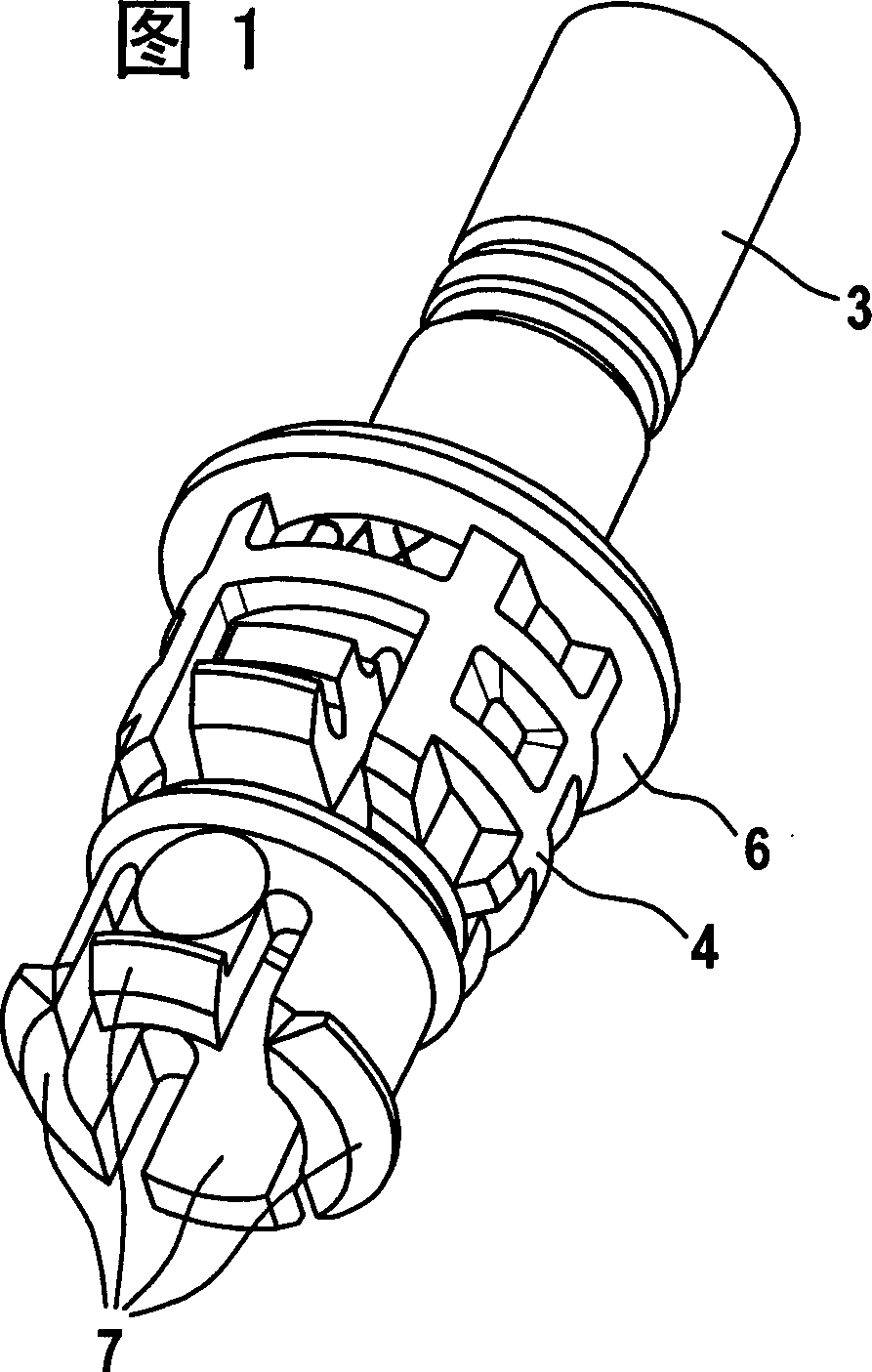

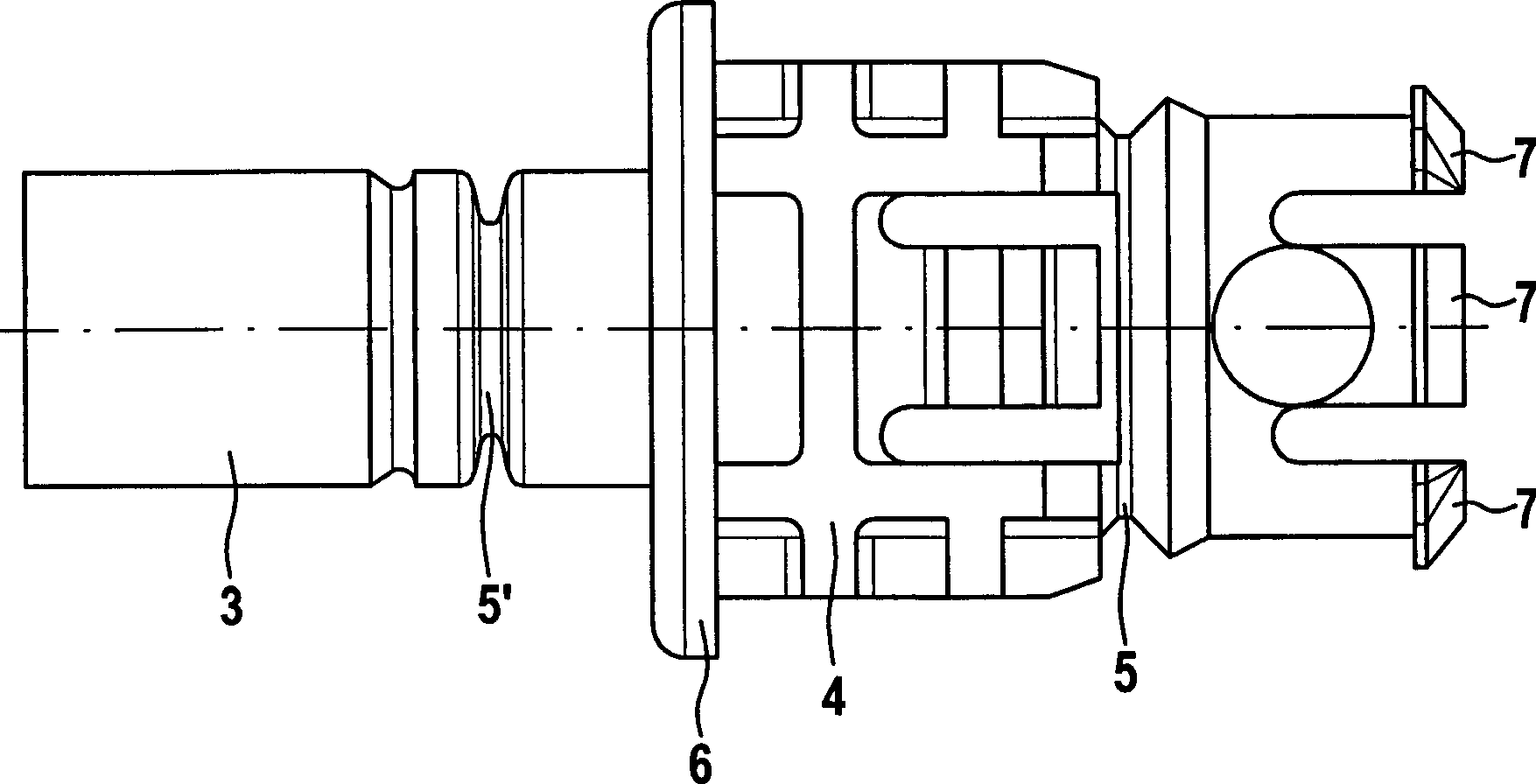

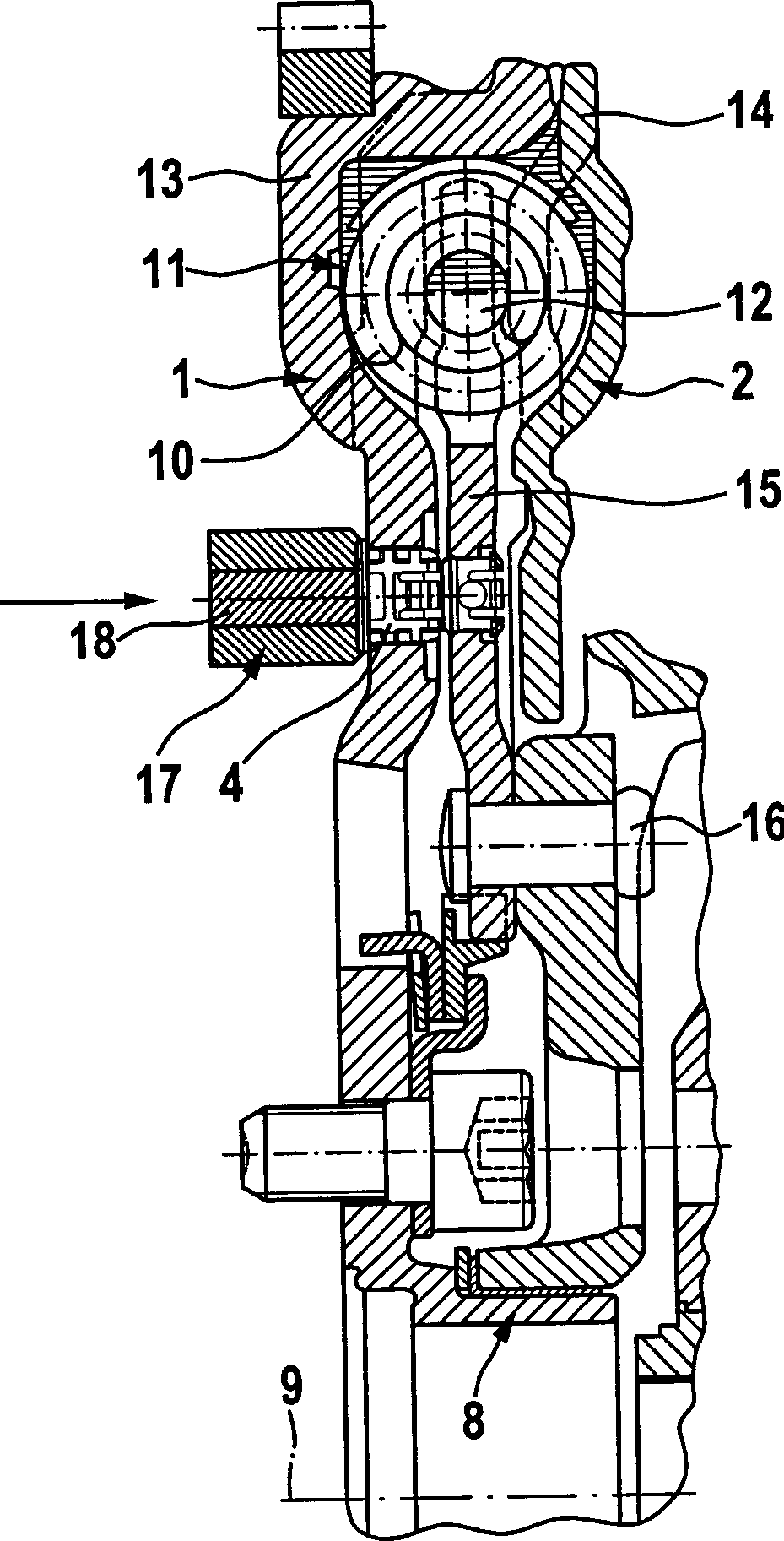

[0027] Figure 1~ Figure 5 A possible embodiment of the mounting fastening device according to the invention is shown in the figure, which is used to lock a primary mass 1 and A secondary mass 2 that can be rotated coaxially relative to the primary mass.

[0028]FIG. 1 shows the mounting fixture according to the invention with a connecting part comprising a sleeve part 4 with a movable journal part 3 . Here, the journal part 3 and the sleeve part 4 have an approximately rotationally symmetrical cross-sectional shape. The journal part 3 has an outer diameter which matches the inner diameter of the sleeve part 4 . figure 2 A side view of the preassembled mounting fixture according to FIG. 1 is shown. In this case, the journal part 3 is inserted approximately into the sleeve part 4 , so that the journal part 3 is fastened on the sleeve part 4 in a detachable manner. This results in a quasi-one-piece mounting fixture according to the invention, which can be produced in a ready...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com