Lock structure

A technology of structure and snap-fit holes, which is applied to quick-action fasteners, electrical components, flip/rocker switches, etc., can solve problems such as poor contact of the switch mechanism, and achieve the effect of preventing flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

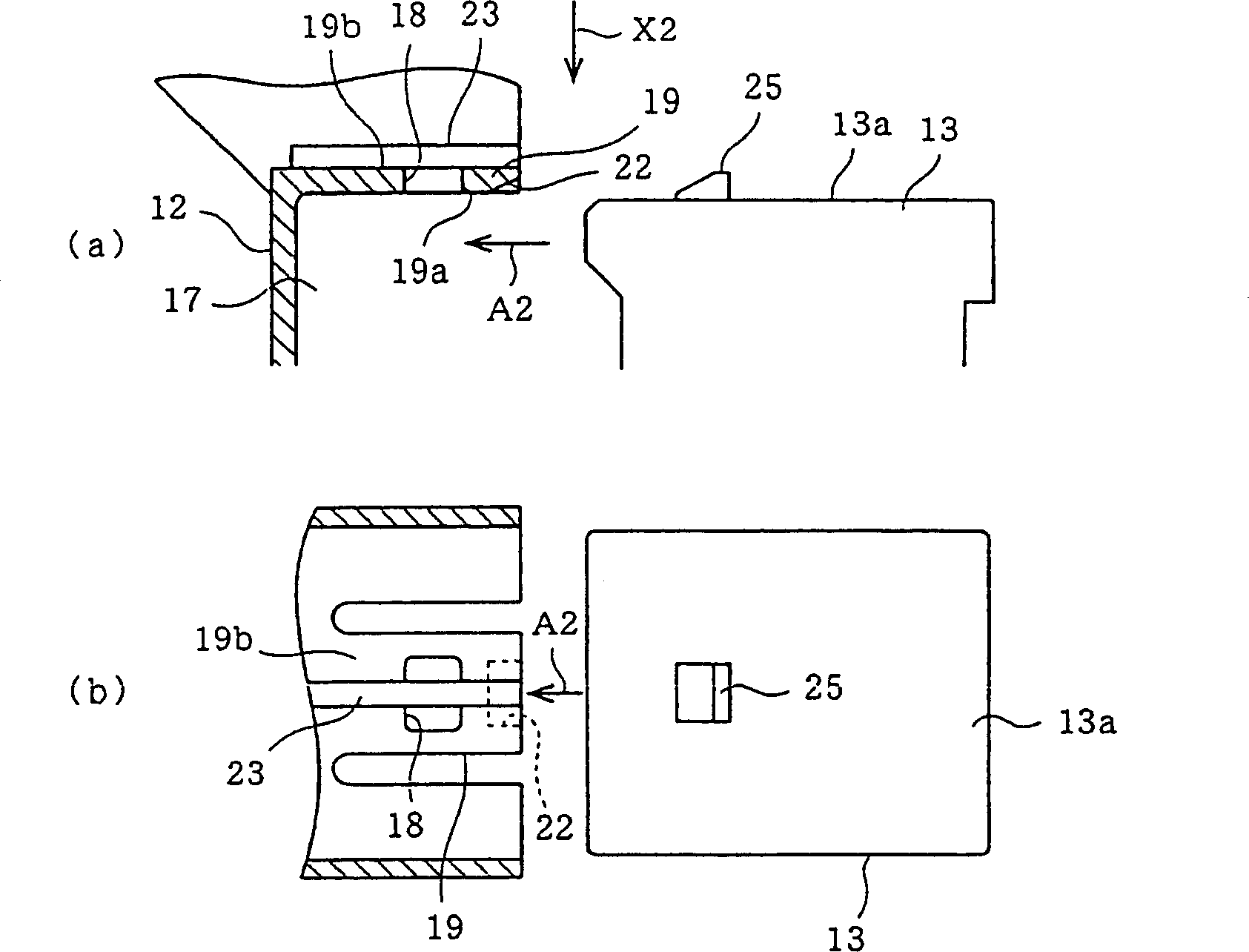

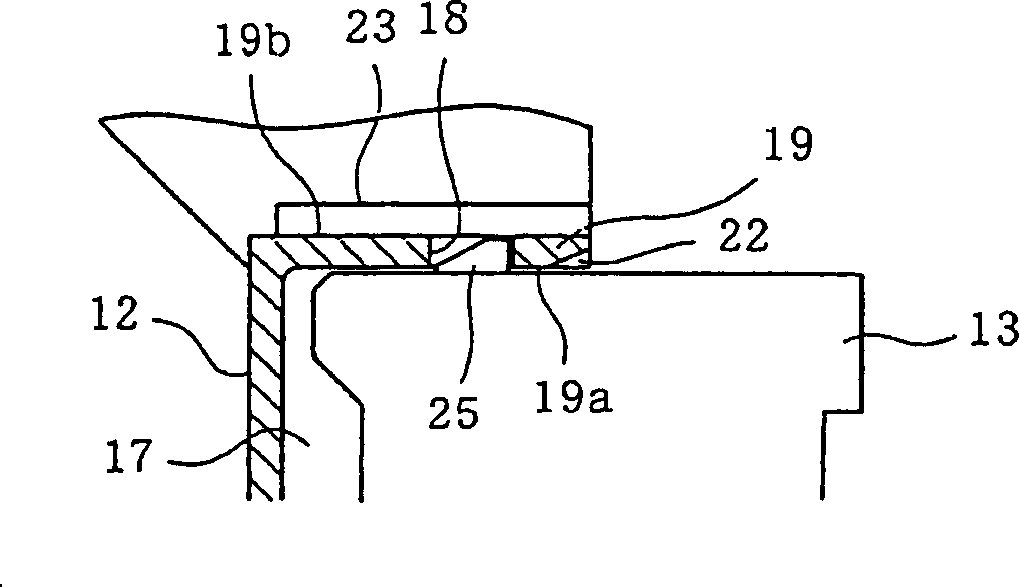

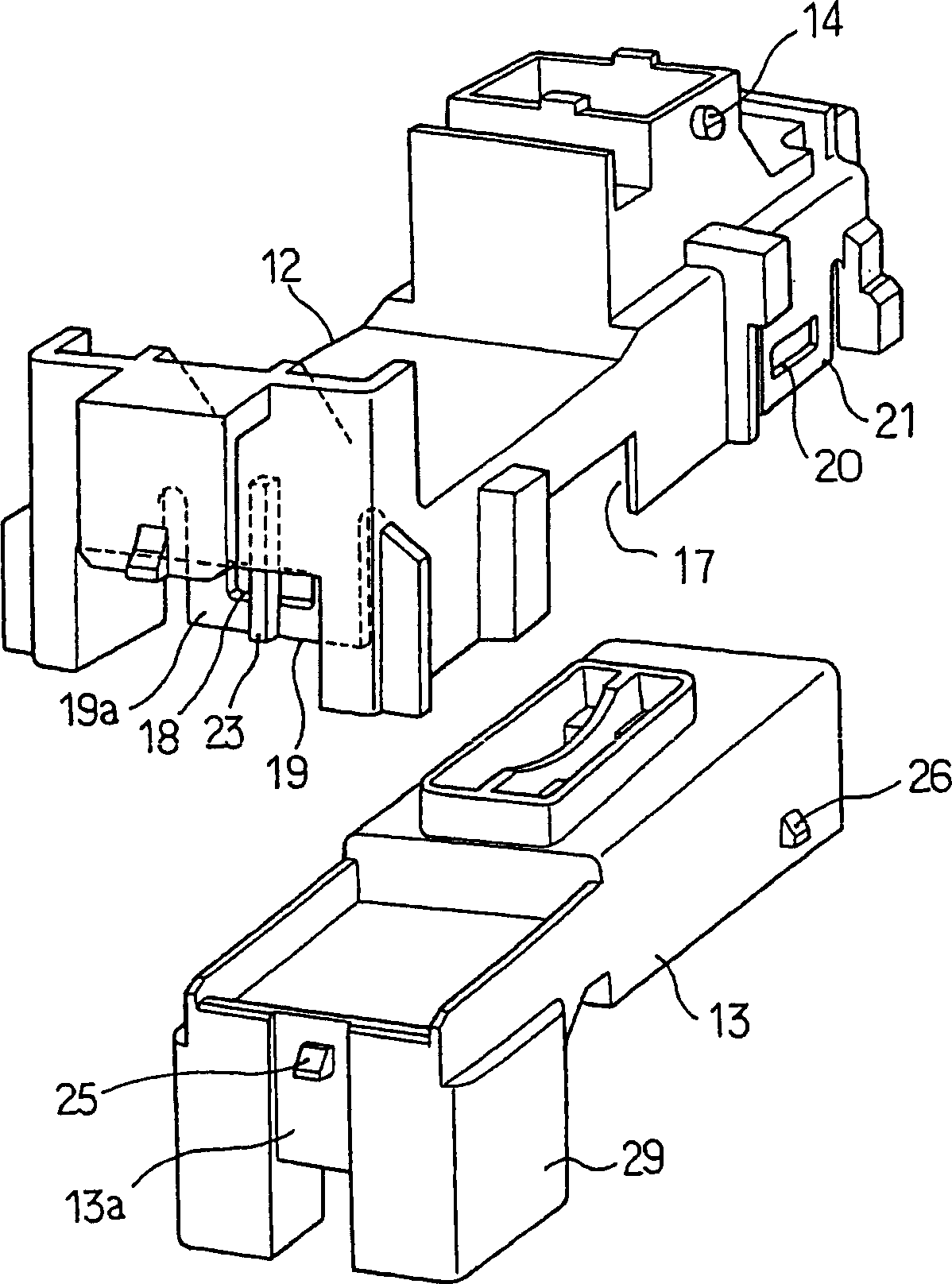

[0020] Below, refer to Figure 1 to Figure 6 An example of the present invention will be described.

[0021] First, in Figure 4 as well as Figure 5 In Fig. 1 , a switch device 11 for a window regulator in automatic opening and closing of windows of an automobile is shown. This switch device 11 is made up of following parts: switch main body 12, the insulator 13 that is assembled in the bottom of this switch main body 12, the operation button 15 that is installed on the top of switch main body 12 and can shake by shaft 14, is arranged in switch main body 12 inside The switch mechanism 16 (refer to Figure 5 ).

[0022] Among them, the switch main body 12 is formed of synthetic resin such as ABS resin, and at its lower part, such as image 3 As shown in FIG. 2 , a receiving portion 17 of a rectangular frame body with an open bottom side is formed. At the front of the peripheral wall portion of the receiving portion 17 ( image 3 as well as Figure 5 The left side in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com