Metering display with automatic temperature difference compensation for oil filling machine

A technology of temperature difference compensation and display, applied in the electrical field, can solve problems such as inaccurate measurement and achieve the effect of protecting fairness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

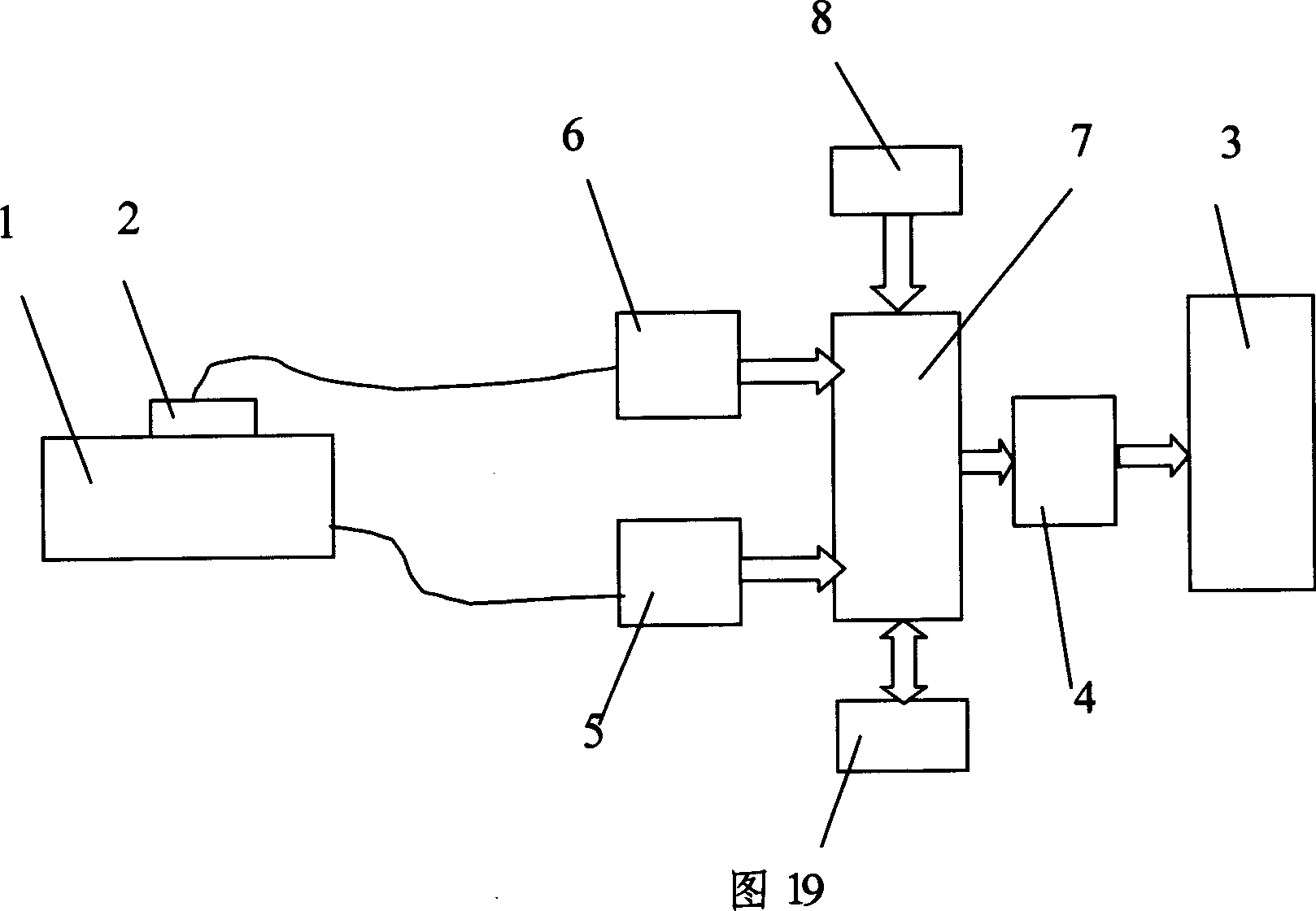

[0011] As shown in Figure 1, the fuel dispenser metering display of automatic temperature difference compensation of the present invention is made of flowmeter 1, temperature sensor 2 and electronic counter, and described flowmeter 1 is provided with flow signal output interface, and in described electronic counter A flow signal input interface is provided, a display 3, a display drive circuit 4 and a power supply circuit are provided in the electronic counter, and the display 2 is connected to the display drive circuit 4, wherein the electronic counter is provided with There is a first analog-to-digital conversion circuit 5 and a second analog-to-digital conversion circuit 6, the first analog-to-digital conversion circuit 1 is connected to the flow signal input interface, and the second analog-to-digital conversion circuit 6 Connected with the temperature sensor 2, the temperature sensor 2 is fixedly attached to the flow meter 1, the first analog-to-digital conversion circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com