Method for fabricating curved template for testing design of shoetree

A technology for detecting curves and manufacturing methods, which is applied to measuring devices for feet or shoe lasts, footwear, clothing, etc., can solve the problems of being unable to grasp and control the surface shape and data of the last body, and achieve the improvement of shoemaking technology and shape Beautiful and well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

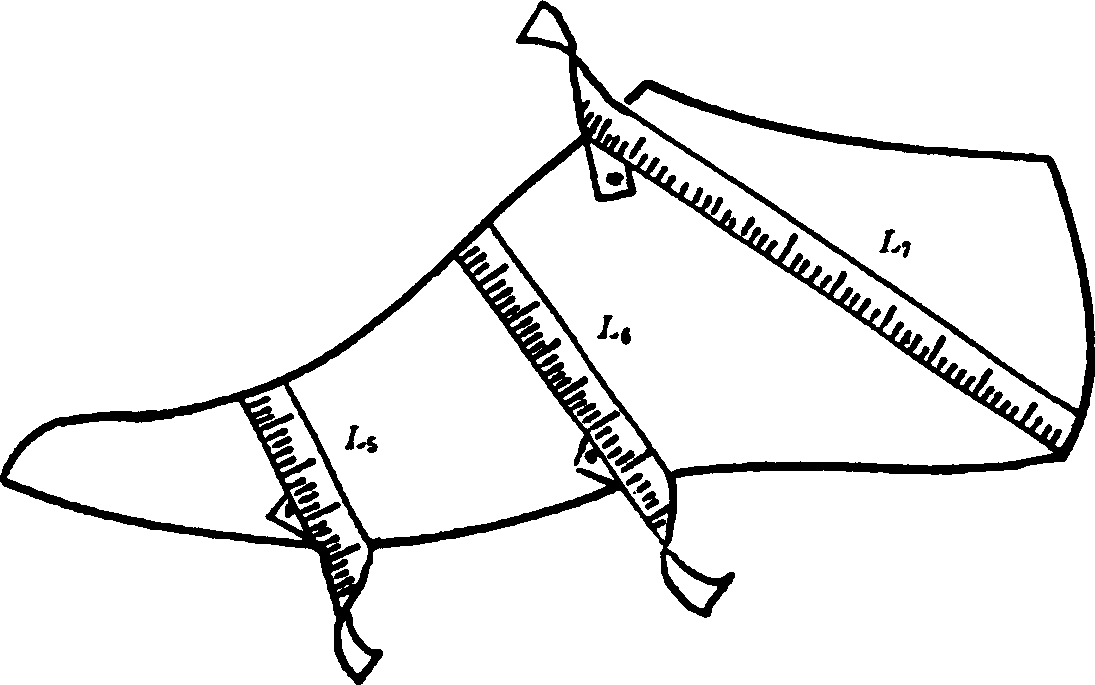

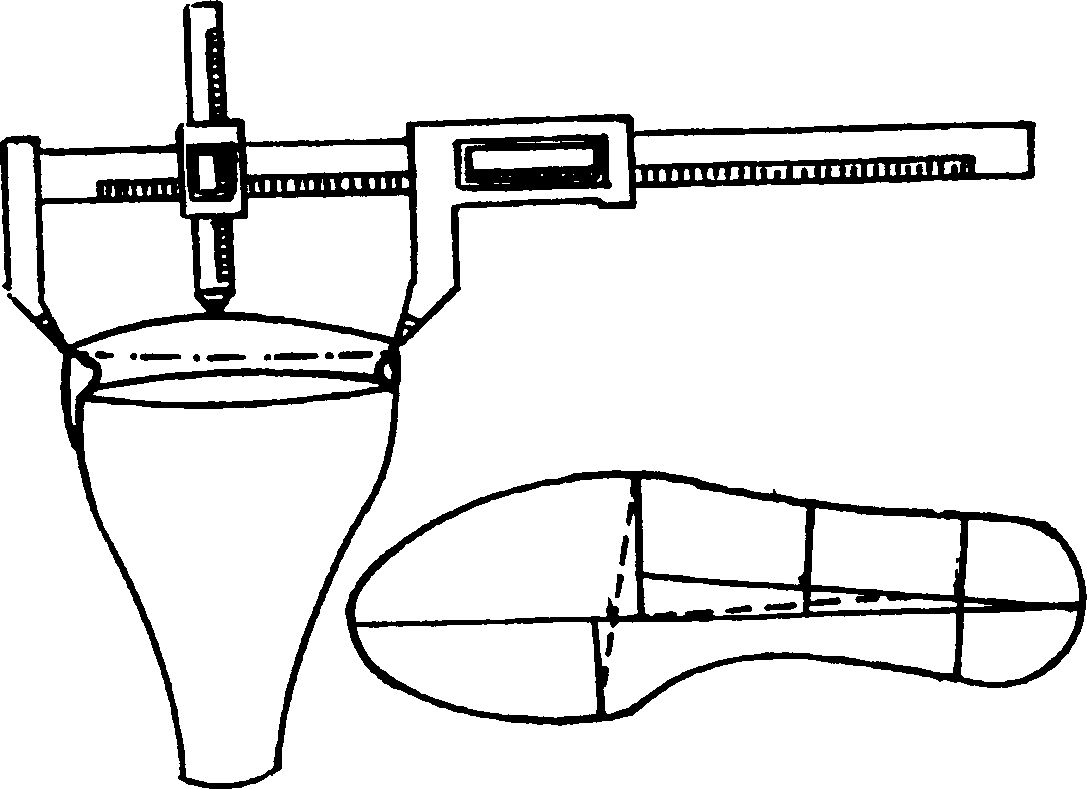

[0028] As shown in Figures 3 and 4, it is a schematic diagram of the design and detection curve clamping board for male and female rear stilt shoe lasts. The manufacturing method of the shoe last design and detection curve clamping board is as follows:

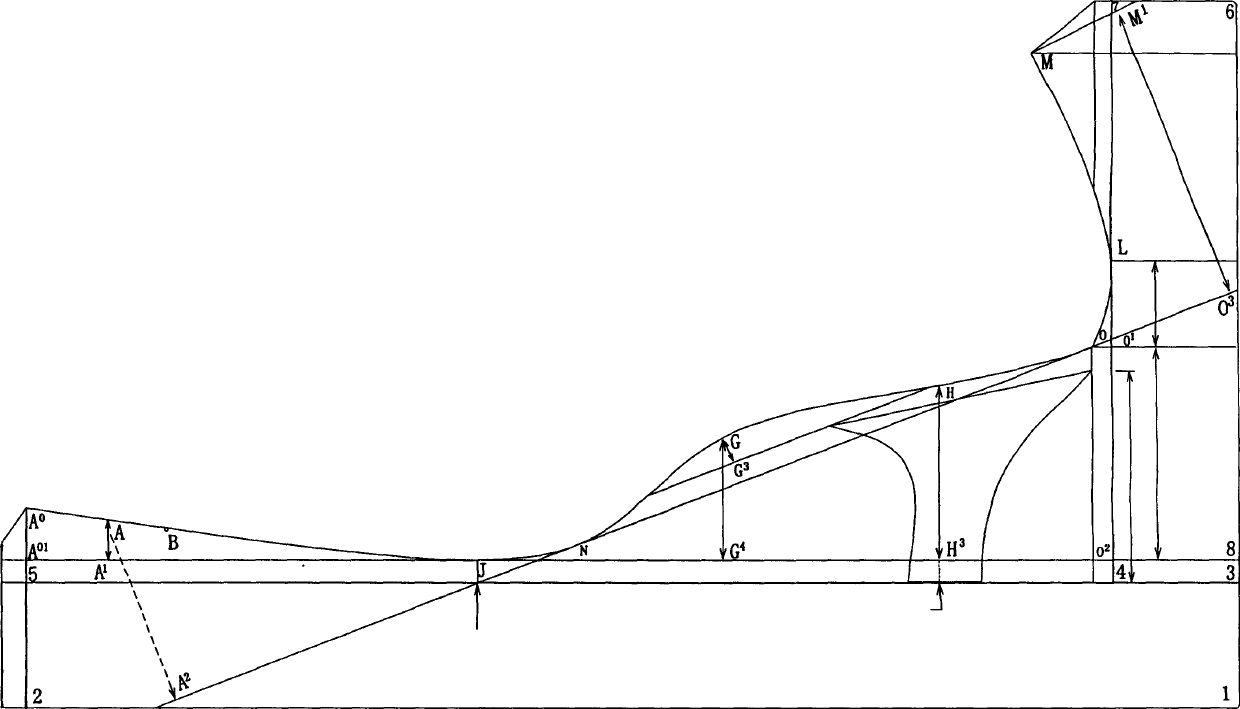

[0029] 1. Select the material with a length of about 280mm-300mm and a height of 180mm-200mm. Establish a straight line under the flat material as the bottom plane (1-2), and make a 90° vertical line perpendicular to the bottom plane at the right end of the bottom plane line. Line (1-6), then draw a parallel line (3-5) at 30mm on the straight line of the bottom plane, and make a vertical line (4-7) parallel to the vertical line at the rear end point at the position 30mm forward of the rear end point .

[0030] Three kinds of materials can be used for shoe last design and detection curve cardboard: ① high-quality kraft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com