Holding and turning over type assembly machine for regulator cubicle

An electrical cabinet and flip-up technology, applied in electrical components, switchgear and other directions, can solve the problems of difficult product quality assurance, high labor intensity of workers, low production efficiency, etc., to improve assembly efficiency and product quality, and reduce handling workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

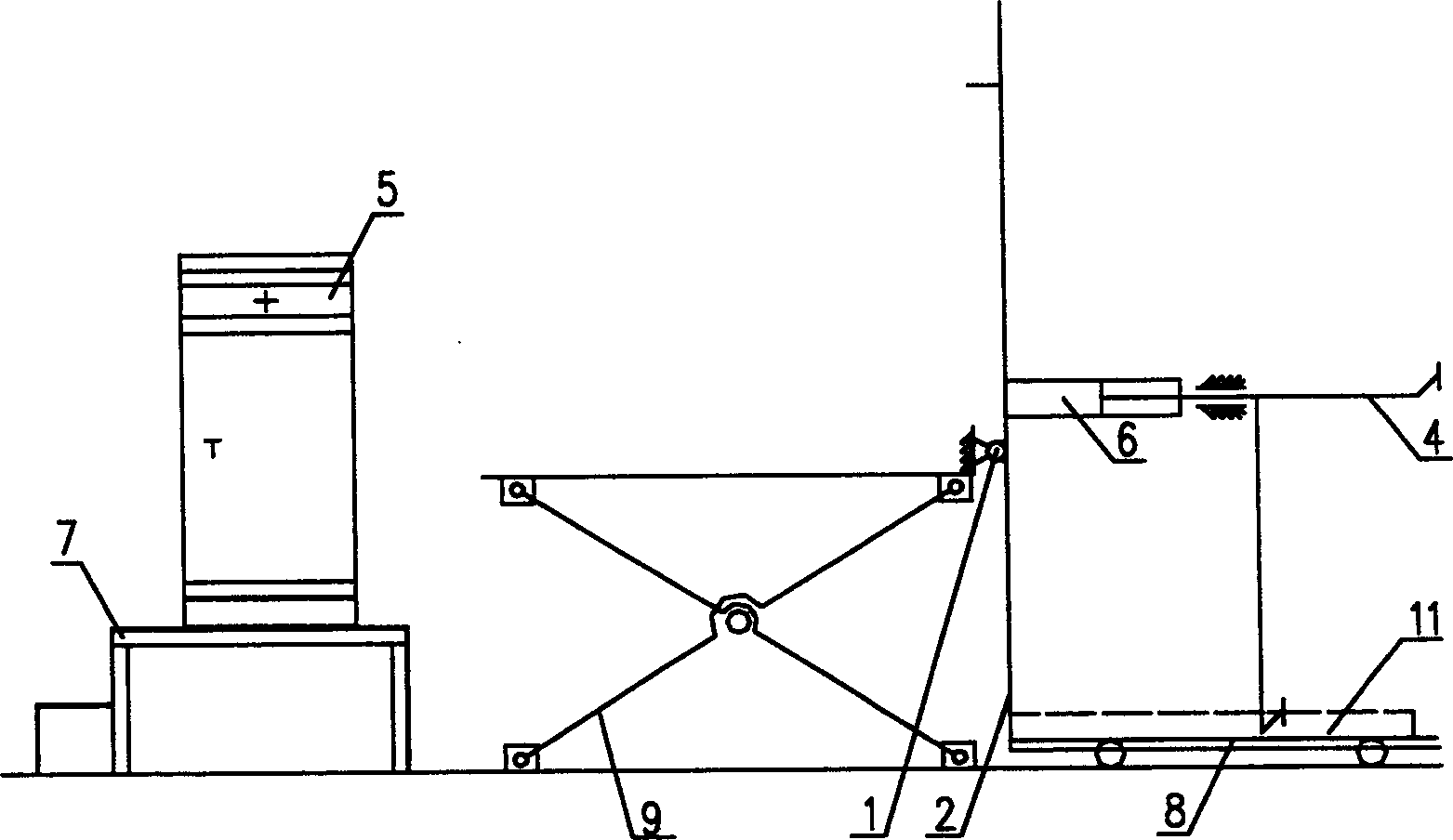

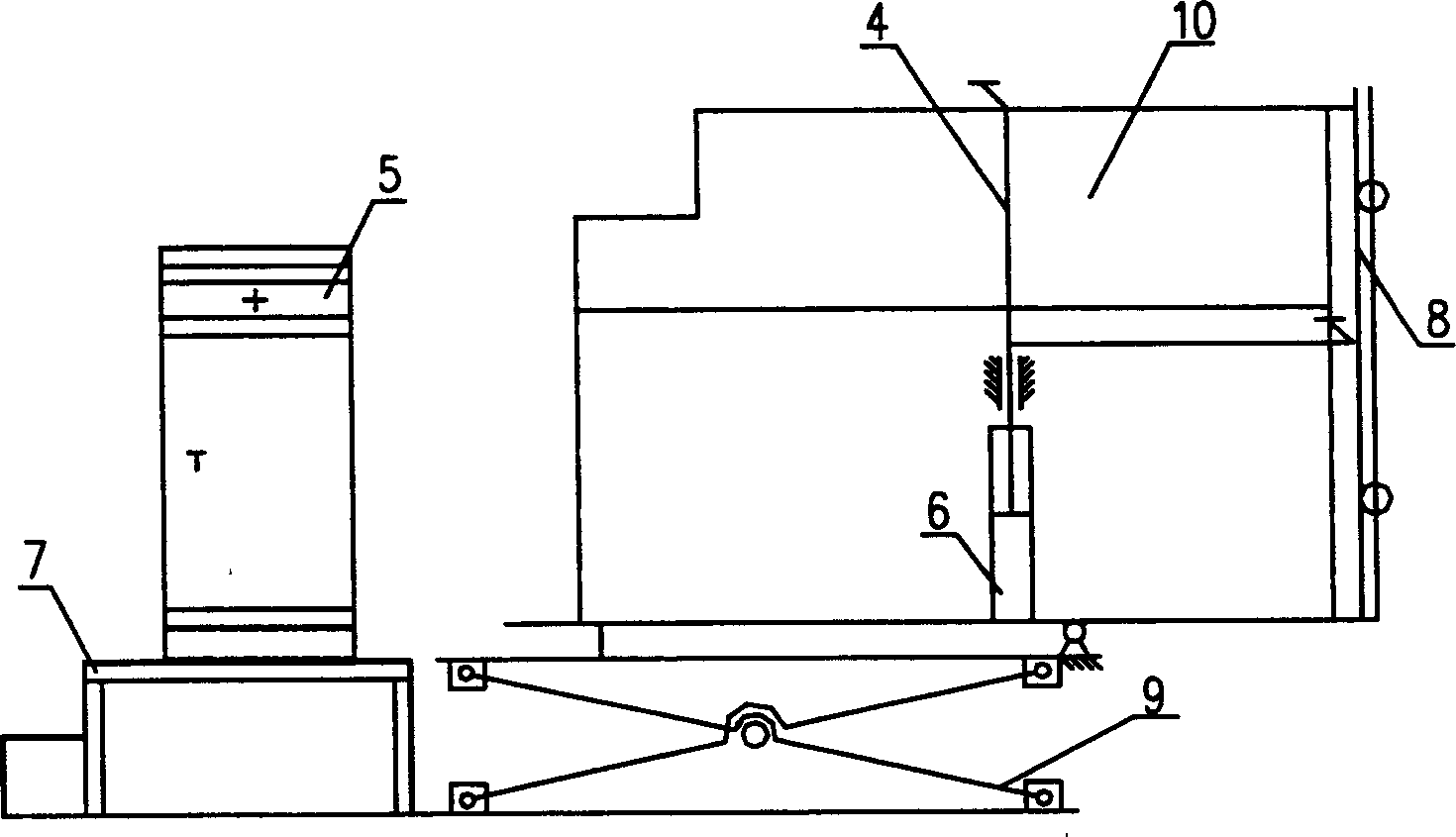

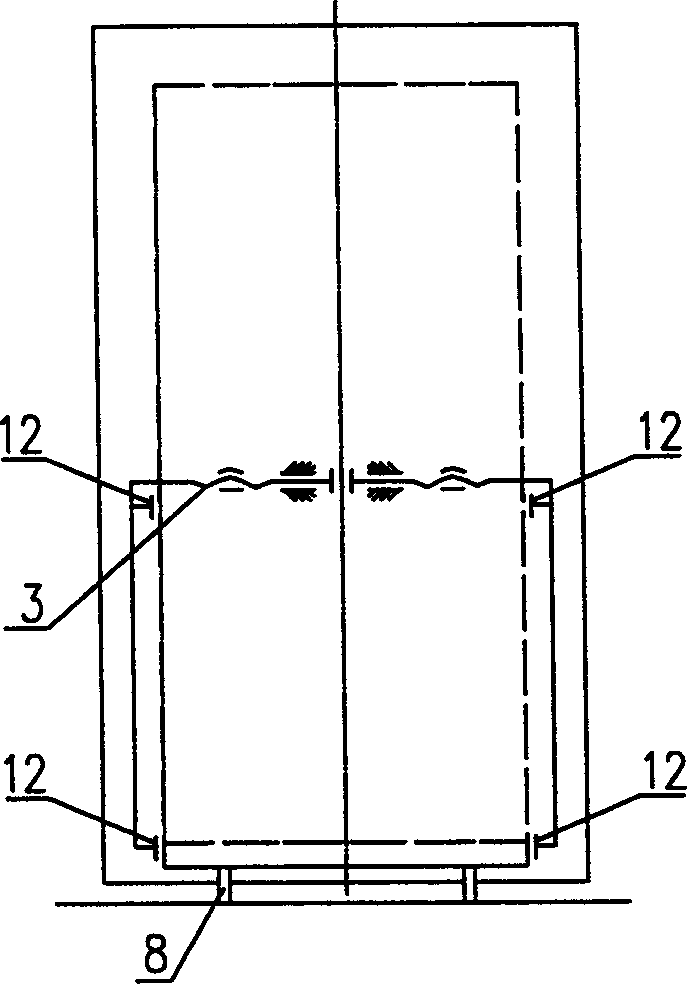

[0006] As shown in the figure, the present invention mainly includes: a turning shaft 1, a turning frame 2, a lateral adjustment mechanism 3, a telescopic clamping mechanism 4, an electric control system 5, a pneumatic system 6, a working platform 7, a turnover vehicle 8, and a lifting platform 9 , electrical cabinet body 10, electrical cabinet body bottom frame 11, and its connection mode is: turning shaft 1, turning frame 2, lateral adjustment mechanism 3, telescopic clamping mechanism 4, lifting table 9 are the main action parts of the present invention, work Platform 7 is the auxiliary work surface of the present invention. The lifting platform 9 is hinged with the turning frame 2 through the turning shaft 1, and the turning frame 2 can be turned 90 degrees around the turning shaft 1 on the lifting platform 9; the lateral adjustment mechanism 3 is composed of a motor, a slider, a screw rod and a guide rod. Installed on the flip frame, the motor drives the screw to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com