Stamping die with good durability

A stamping die and durability technology, applied in the field of stamping dies, can solve the problems of long processing cycle, easy corrosion and wear, and increase the workload of operators, so as to reduce the handling workload, improve work efficiency, and shorten the processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

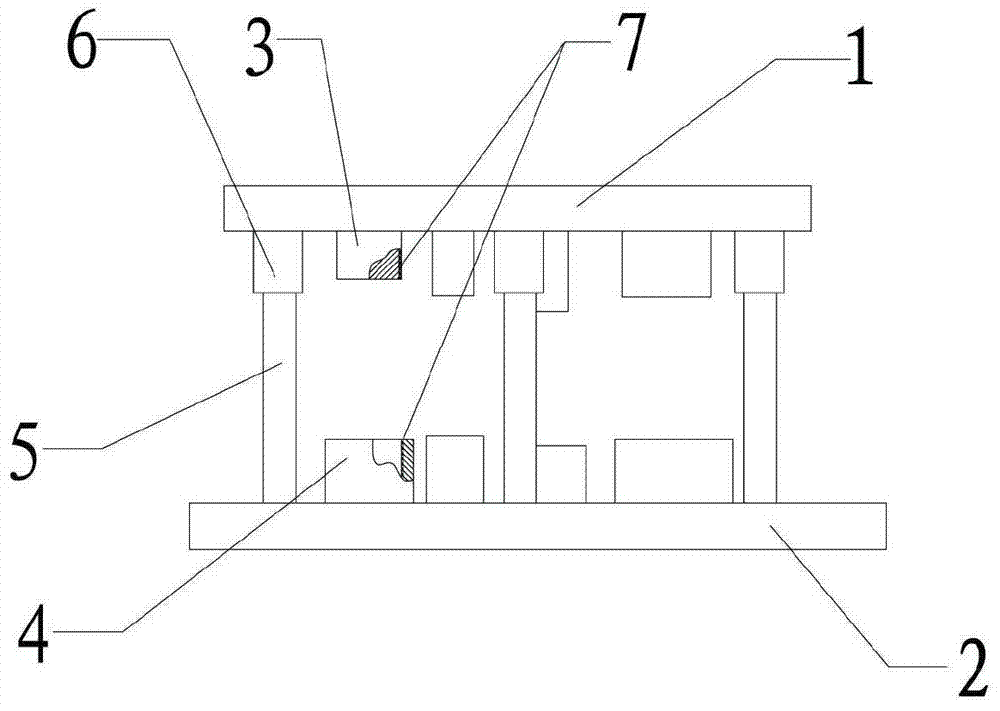

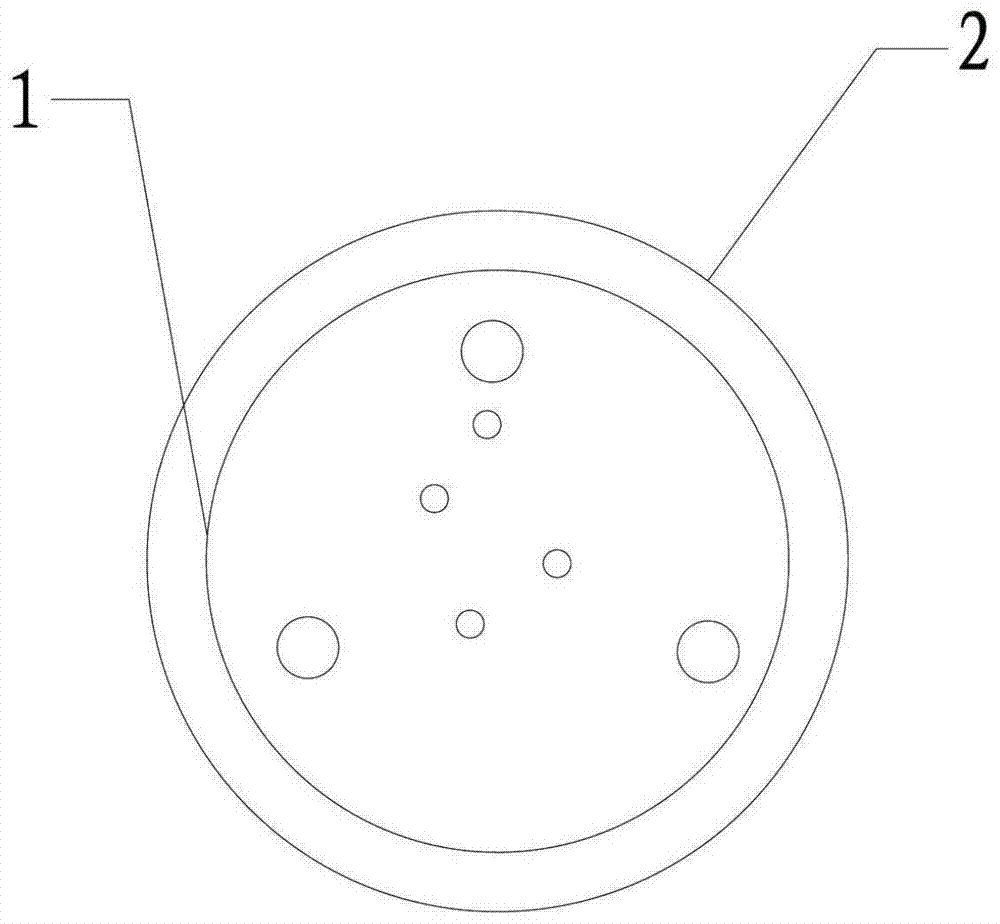

[0013] Such as figure 1 , figure 2 As shown, a stamping die with good durability includes upper and lower mold bases 1, 2 and corresponding convex and concave molds 3, 4 that are installed on the opposite surfaces of the upper and lower mold bases 1, 2 to cooperate with each other, wherein , the upper and lower mold bases 1 and 2 are both in the shape of a round cake, and they are guided by three sets of mutually matching guide posts 5 and guide sleeves 6 arranged equidistantly along their circumference, and the mutual There are four sets of matching convex and concave molds 3 and 4, and the outer surface of each convex mold 3 and the inner surface of each concave mold 4 are provided with a corrosion-resistant layer 7 made of silicon carbide ceramics. The thickness of layer 7 is 1-10 nanometers. After adopting the above design, du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com