Method for manufacturing multi-layer combined macromolecular PTC chip

A multi-layer composite and high molecular polymer technology, which is applied in the field of high molecular PTC thermistor chip structure and its manufacturing, can solve the problems of component burning, achieve long-term performance improvement, reduce the possibility of burning, and reduce resistance drift Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

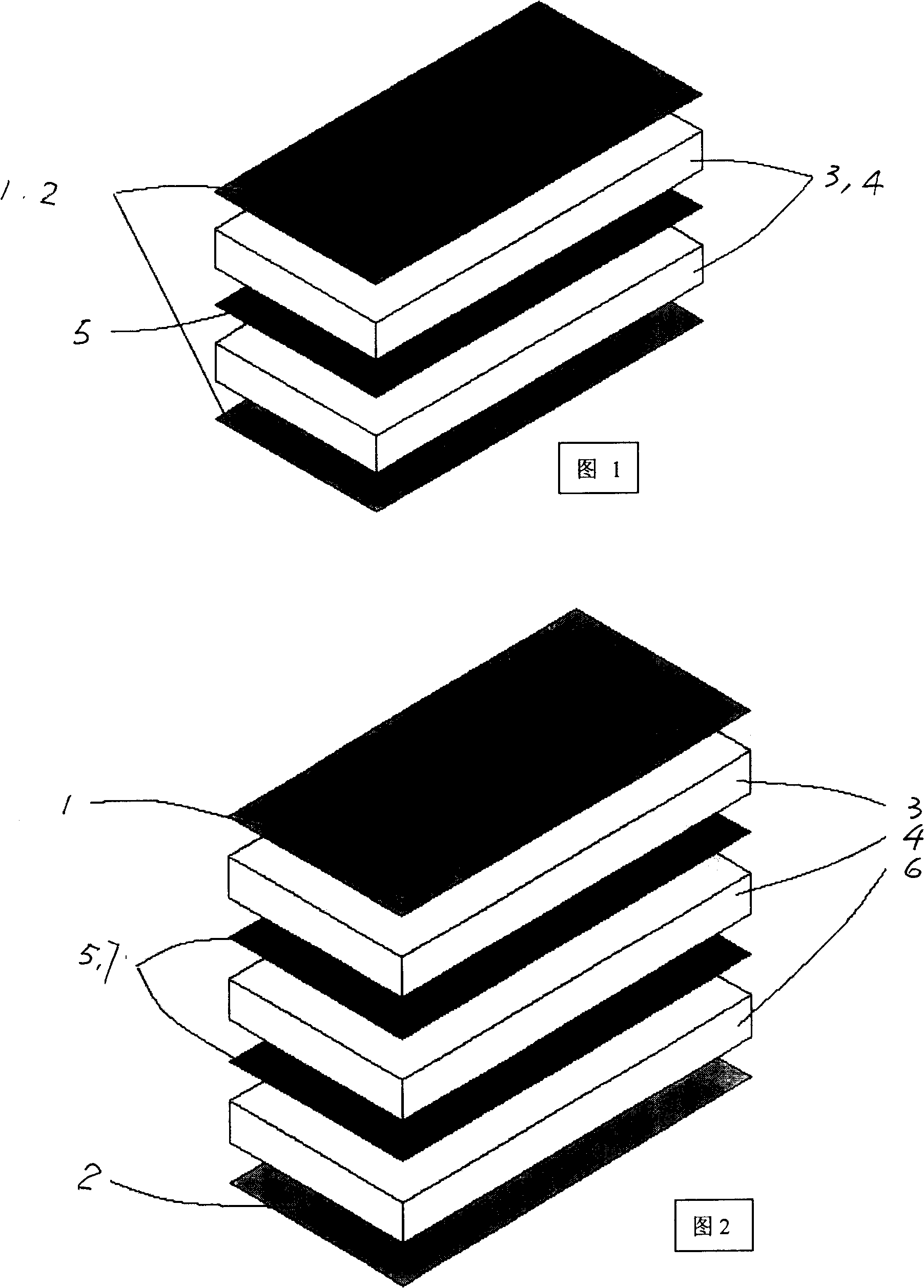

[0019] Such as figure 1 As shown in the schematic diagram of the multilayer composite structure of the polymer PTC chip, the polymer PTC material layer is two layers, and a copper sheet layer 5 is added between the two layers of polymer PTC material layers 3 and 4, and the upper and lower layers of the polymer PTC material layer Electrode sheets 1 and 2 are compounded on the surface layer.

[0020] The manufacturing method of this structure is: mix high-density polyethylene, carbon black, nano-calcium carbonate, magnesium hydroxide and antioxidant in a high-speed mixer for 10 minutes in a certain proportion. Then mix each component of the mixture in an internal mixer at a temperature of 180°C, and after cooling and crushing, put it in a compression mold with a pressure of 5 MPa and a temperature of 180°C to form an area of 200 cm 2 , 0.8mm thick core material.

[0021] Electrodeposition is used on both sides of a copper foil to make a special copper sheet by co-depositing...

Embodiment 2

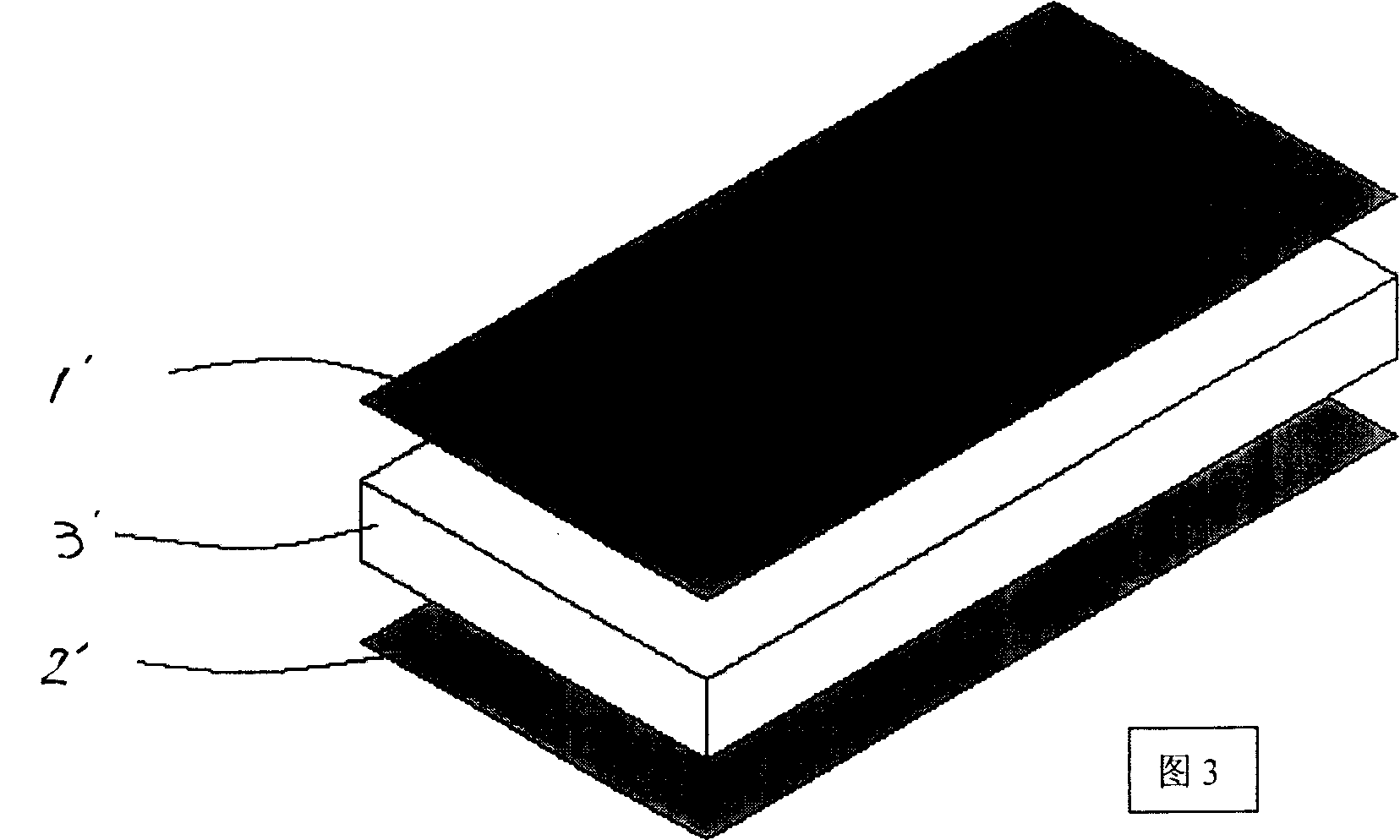

[0025] Such as figure 2 As shown in the schematic diagram of the multilayer composite structure of the polymer PTC chip of embodiment 2, the polymer PTC material layer is three layers, and two copper sheet layers 5,7 are added between the three layers of polymer PTC material layers 3,4,6, That is, a copper sheet layer is added between every two layers of polymer PTC material layers, and electrode sheets 1 and 2 are compounded on the upper and lower surfaces of the polymer PTC material layers.

[0026] Polyethylene, polyvinylidene fluoride, graphite, metal powder, talcum powder, antioxidant, coupling agent are mixed, and its manufacture method is identical with embodiment 1.

[0027] The manufactured polymer PTC thermistor can have small resistance drift after recovery, high long-term performance stability, and at the same time, greatly reduce the possibility of burning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap