Apparatus and method for adding element during metal smelting process

A technology for adding elements and metal melts, applied in the field of metal smelting, can solve the problems of low reduction speed and reduction rate, low alloying element addition, low compound utilization rate, etc., and achieves high production efficiency, high material utilization rate, good The effect of comprehensive technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

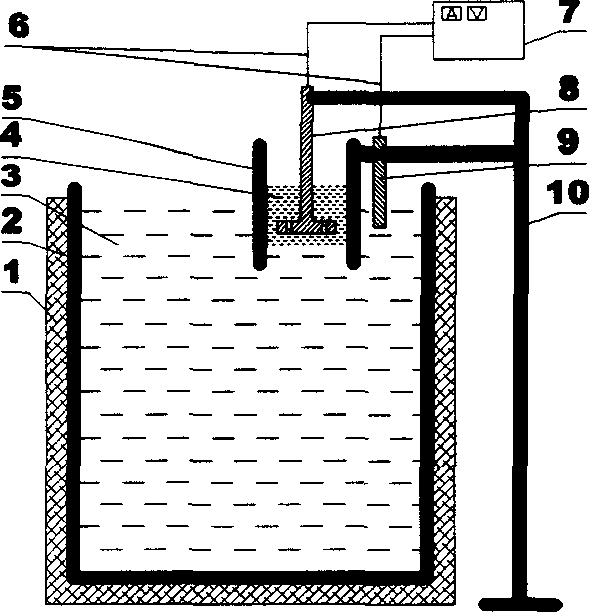

[0023] Example 1: Device and method for adding alloying element Sr in the smelting of Mg-Al-Sr heat-resistant magnesium alloy

[0024] 1. Device

[0025] like figure 1 A device for adding elements in metal smelting is constructed as shown. Among them: melting furnace 1 is a resistance furnace; crucible 2 is made of stainless steel with a volume of 0.0015M 3 ; The electrolytic cell 5 is made of graphite, with a volume of 0.000225M 3 ; The electrolysis power supply 7 is a 10KVA DC power supply; the electrodes 8 and 9 are made of graphite.

[0026] 2. Method

[0027] Preparation of Mg-Al alloy melt: Add 2Kg of metal magnesium into the crucible, heat to 700°C, add 0.12Kg of metal aluminum, and stir until the metal aluminum melts to obtain a Mg-Al alloy melt.

[0028] Molten salt preparation: formula: SrO 100g, KCl 50g, cryolite 30g. Dry, mix evenly, add to the surface of the Mg-Al alloy melt in the installed electrolytic cell, wait for 5 minutes, and form molten salt.

[00...

Embodiment 2

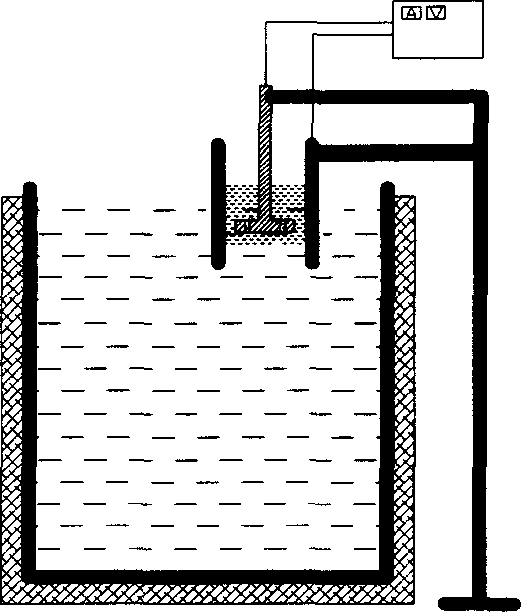

[0032] Embodiment 2: Device and method for adding alloy element Sr in Mg-Al-Sr alloy smelting

[0033] In addition to devices such as figure 2 Except shown, remaining is the same as embodiment 1.

Embodiment 3

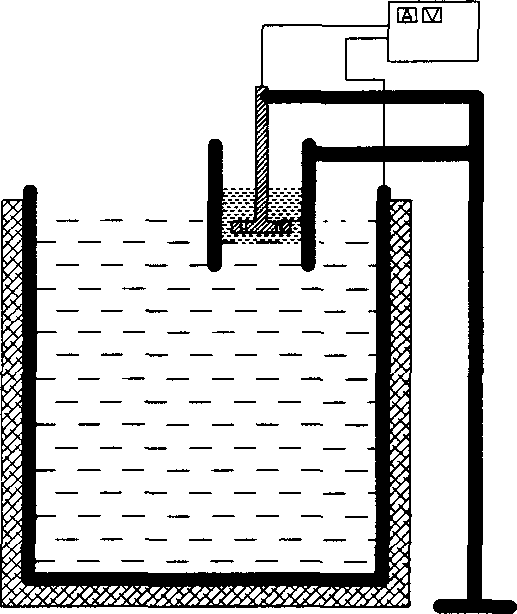

[0034] Embodiment 3: Device and method for adding alloy element Sr in Mg-Al-Sr alloy smelting

[0035] In addition to devices such as image 3 Except shown, remaining is the same as embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap