Transverse fabric clamping and tensioning device

A tensioning device and fabric technology, applied in the field of stretching device and fabric horizontal clamping, to achieve the effect of ensuring processing quality and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

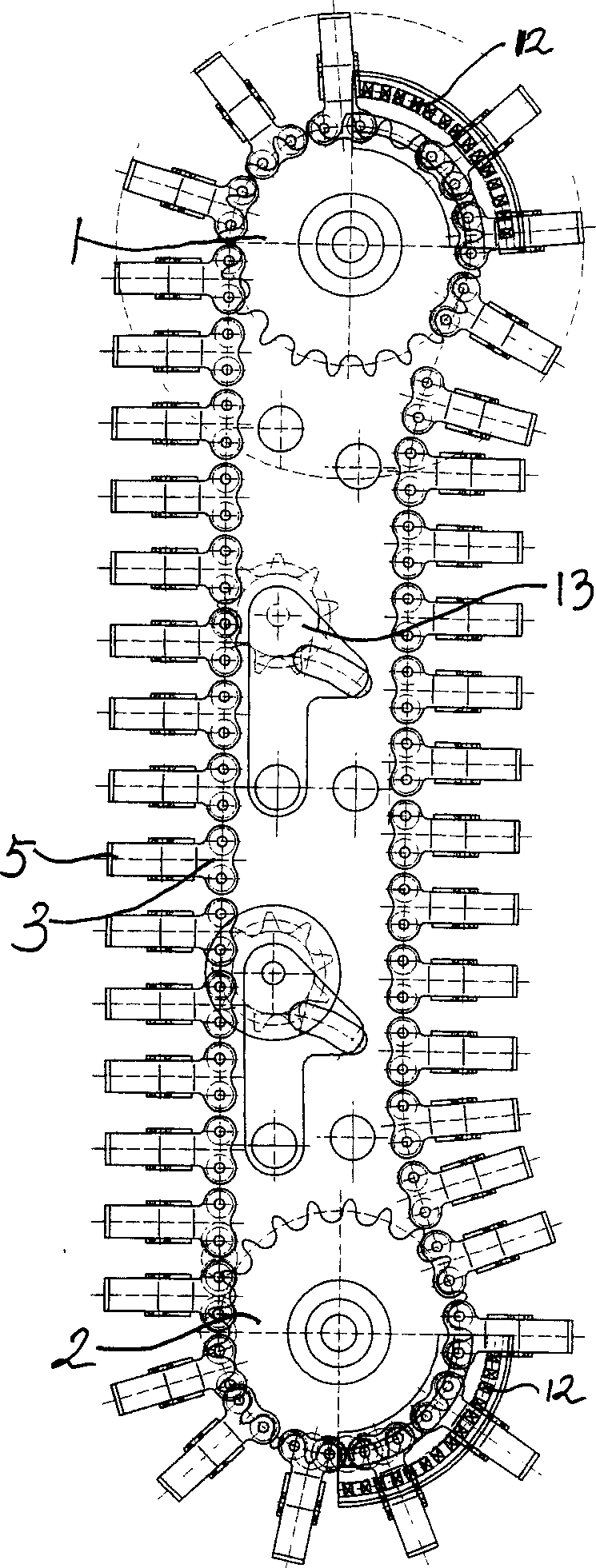

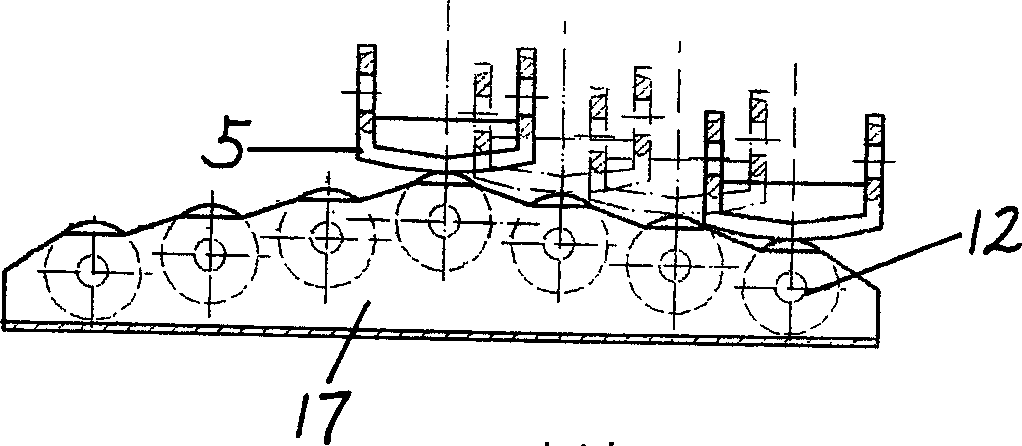

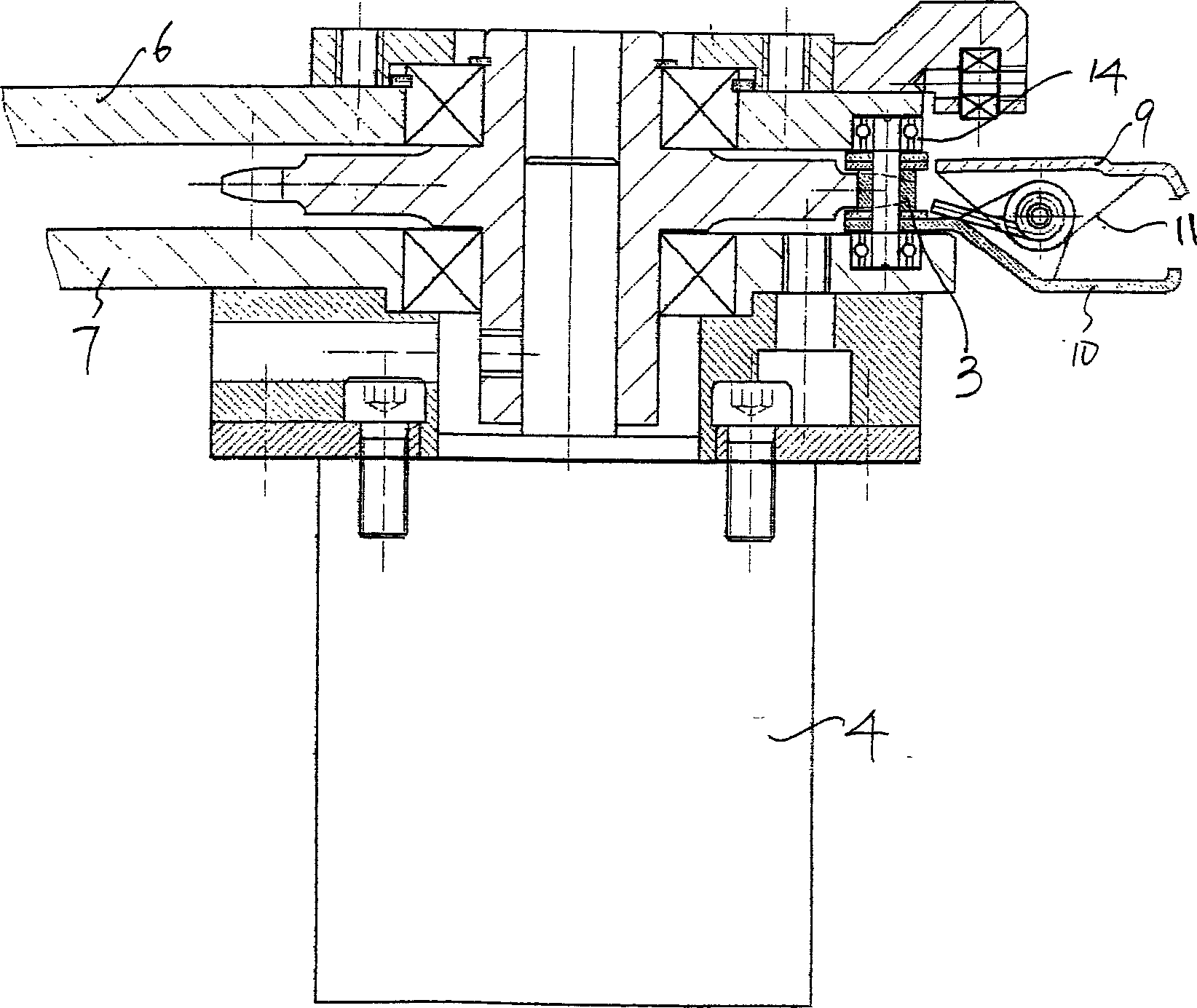

[0014] A horizontal fabric clamping and tensioning device, with a chain 3 driven by sprockets 1 and 2, the sprockets are driven by a stepping motor 4, and each link of the chain 3 is equipped with a fabric that is opened and clamped by a switch mechanism Clamp 5, chain both sides load up and down cover plate 6,7, the chain track groove 8 of limiting chain motion locus is set on the upper and lower cover plate. The side of the chain track groove 8 is inwardly concave to the side of the fabric, which can further make the fabric clip 5 implement the tensioning effect on the fabric 15 . Fabric clip 5 is elastic clip, is made up of upper and lower clip 9,10 and button spring 11. The fabric clip switch mechanism is a top-opening switch device arranged on the upper cover plate 6. The top-opening switch device has a plurality of bearings 12 arranged on the upper cover plate 6 outside the sprockets at both ends and arranged along the chain movement direction. A plurality of bearings 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com