Damping matching test method and system based on magneto-rheological technology for automobile suspension system

A magnetorheological damper, automotive suspension technology, applied in vehicle testing, machine/structural component testing, instruments, etc., can solve the problems of long test cycle, difficulty in achieving damping matching, and inability to continuously adjust, and shorten the Test period, effect of reducing test intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

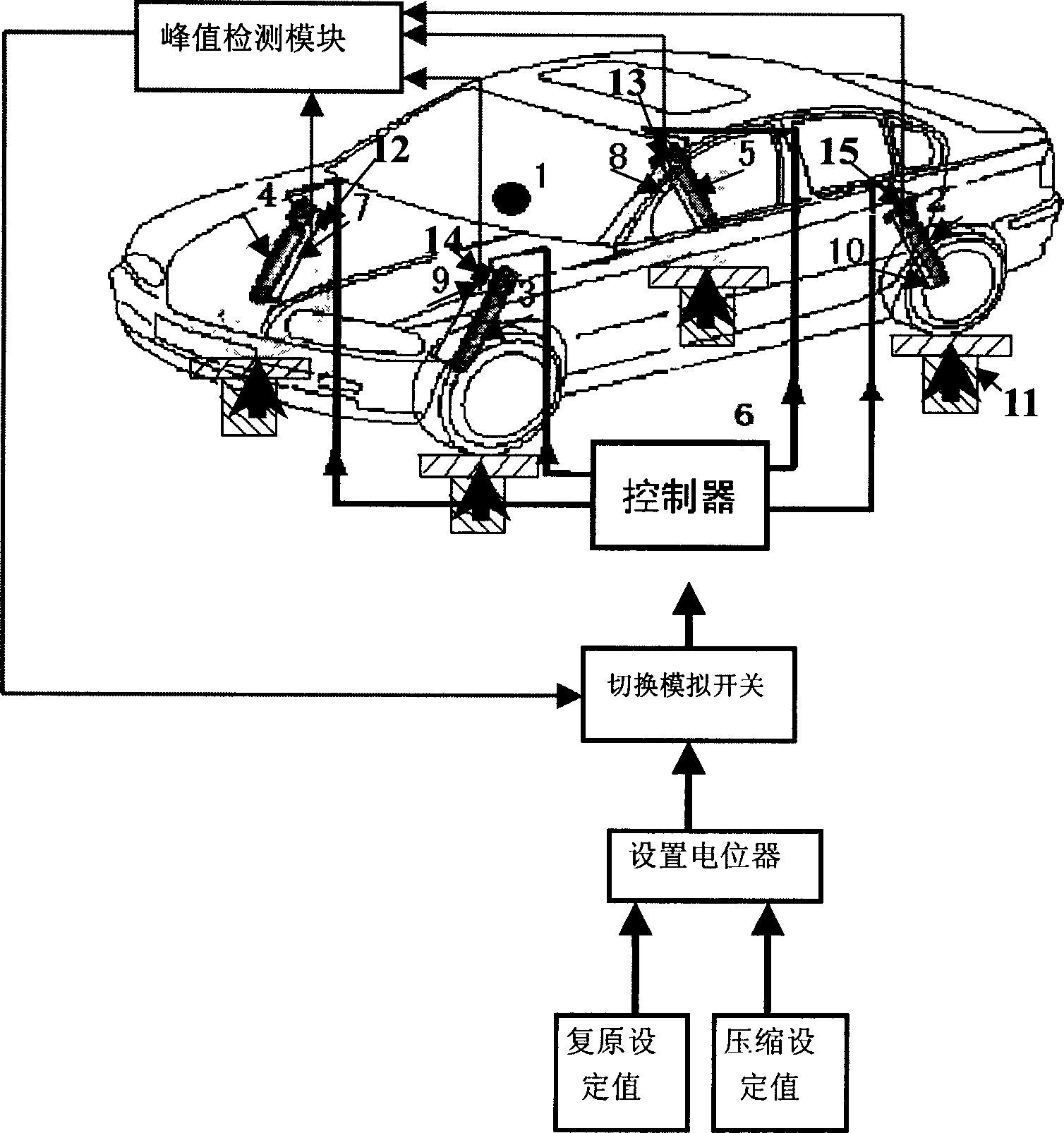

[0028] Such as figure 1 The bench test system with matching damping is shown. The system is composed of test vehicle, excitation platform, magnetorheological damper 2~5, displacement sensor 7~10, force sensor 12~15, peak detection module, switch analog switch and feedback The controller 6 is composed of the four wheels of the car respectively placed on the four actuating heads 11 of the excitation platform, and the four actuating heads move up and down to simulate the driving conditions of the car on the road and test the suspension of the vehicle The installation is a magnetorheological damper (MRD) 2-5, a displacement sensor (LVDT) 7-10 and a force sensor 12-15 are also installed on the vehicle suspension, and the displacement sensor, magnetorheological damper and force The sensors are respectively connected with the peripheral peak detection module, the switching analog switch and the feedback controller 6 through signal lines to form a vehicle damping matching test system tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com