Damping matching test method and system for automobile suspension system based on magnetic rheology technology

A technology of magnetorheological damper and automobile suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

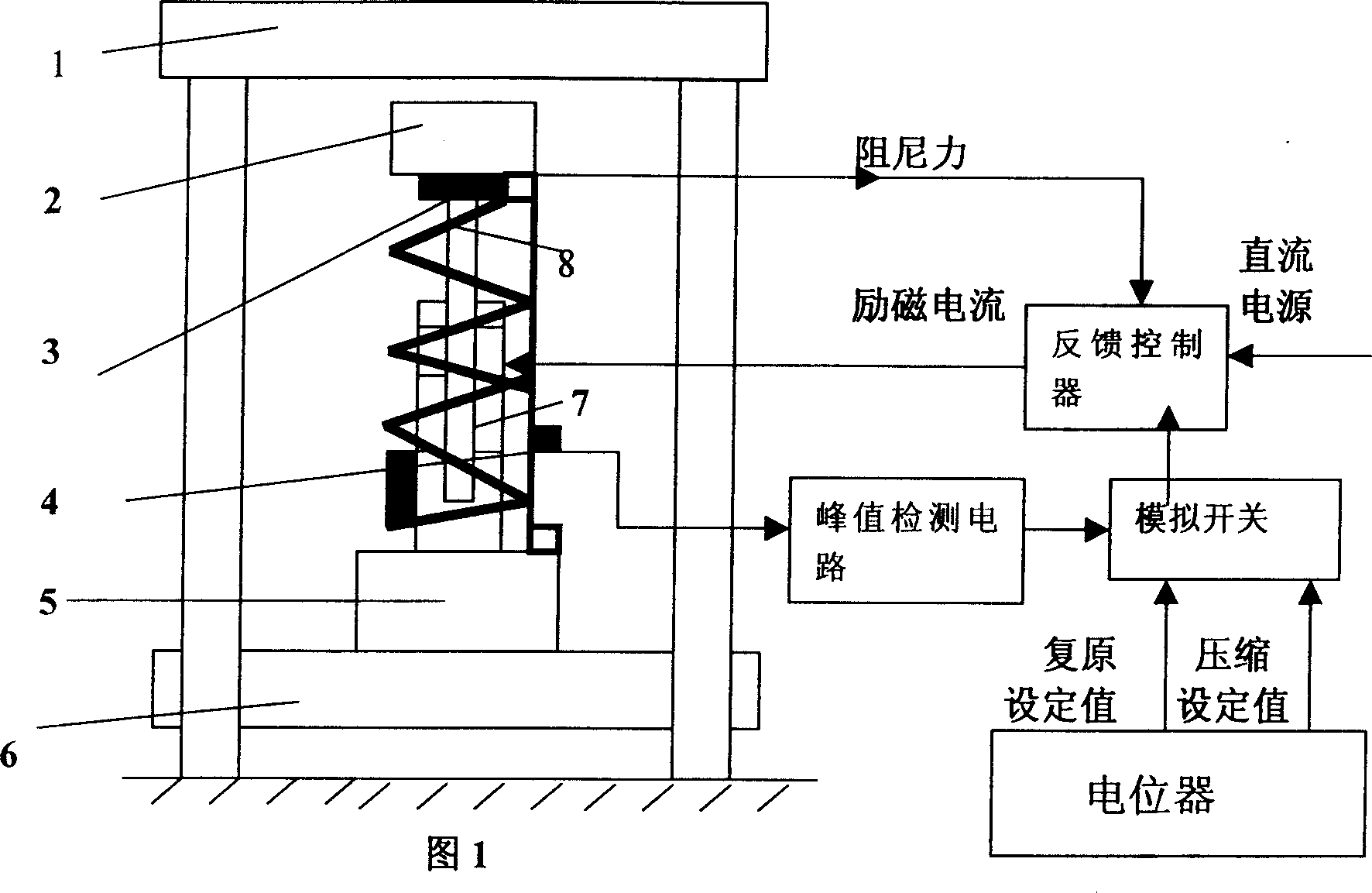

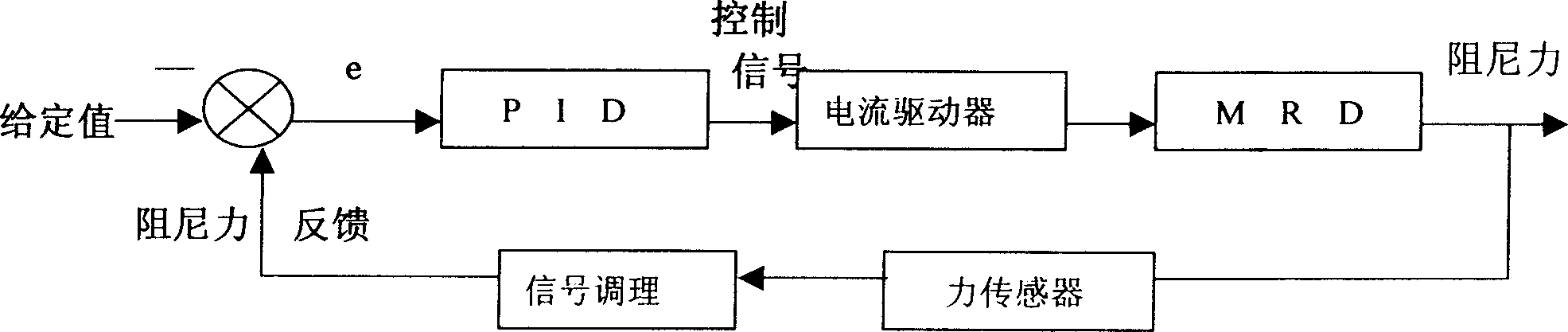

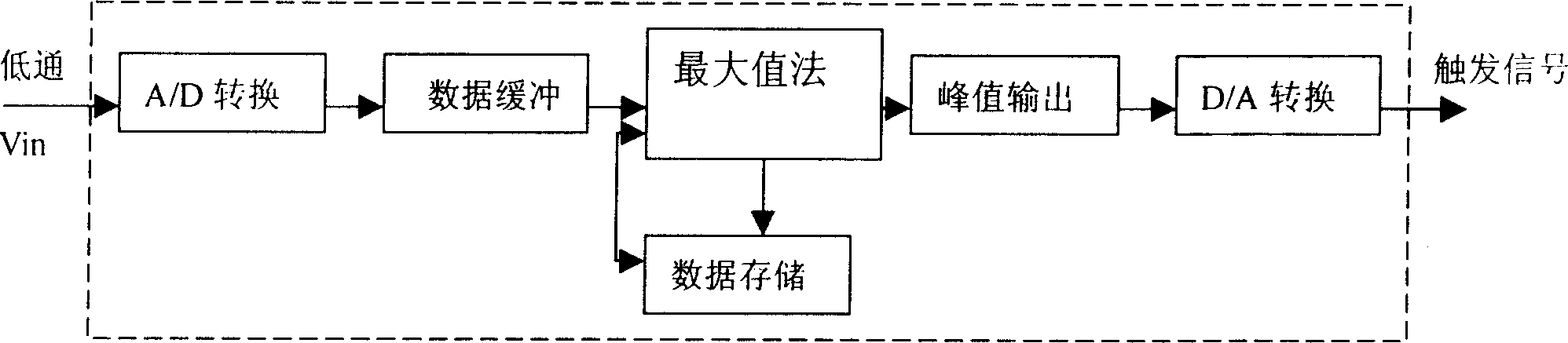

[0025] As shown in Figure 1, the damping matching bench test adopts a 1 / 4 vehicle model, consisting of frame 1, a sprung mass 2 that can move freely in the vertical direction in the frame 1, an unsprung mass 5 connected to the action head 6, and a force sensor 3 between the sprung mass 2 and the unsprung mass 5, a displacement sensor 4, a spring 8 and a magneto-rheological damper (MRD) 7, and the matching peripheral equipment includes a peak detection module, Toggle analog switches, potentiometers, and feedback controllers. In terms of equipment connection, the signal line of the displacement sensor is connected to the peak detection module, and the output signal of the peak detection module is connected to the switching analog switch. Switching the analog switch converts the reset damping value and compression damping value of the required MRD preset by the potentiometer into The voltage signal is connected to the feedback controller as a given value, the control line of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com