Elastic collision buffer for automobile

An elastic buffer, automobile technology, applied in the direction of bumpers, etc., can solve problems such as unpredictable effects, steel sleeve bursting, transformation, etc., to avoid damage to the car body, prolong the deformation time, and increase the effect of the action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

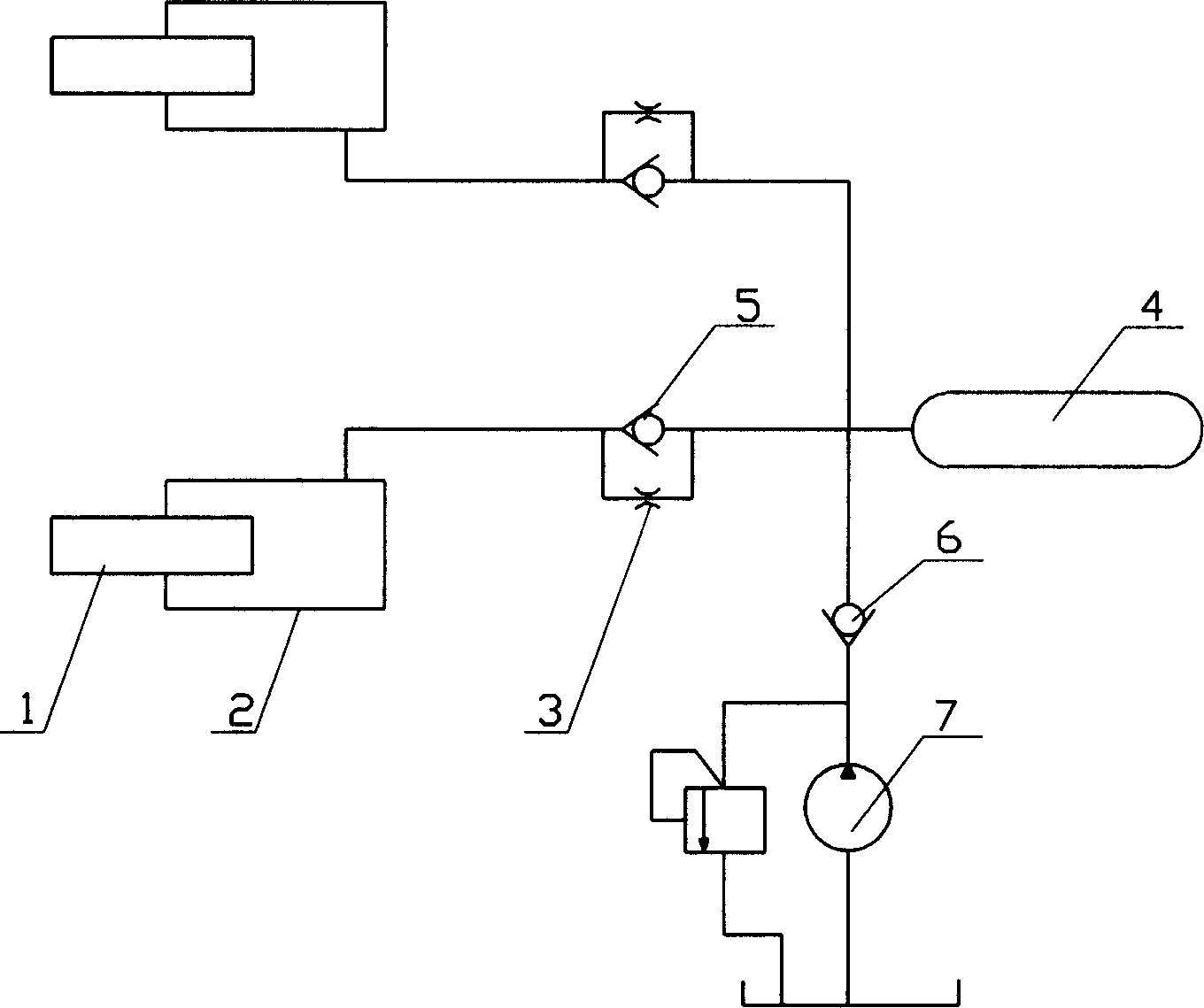

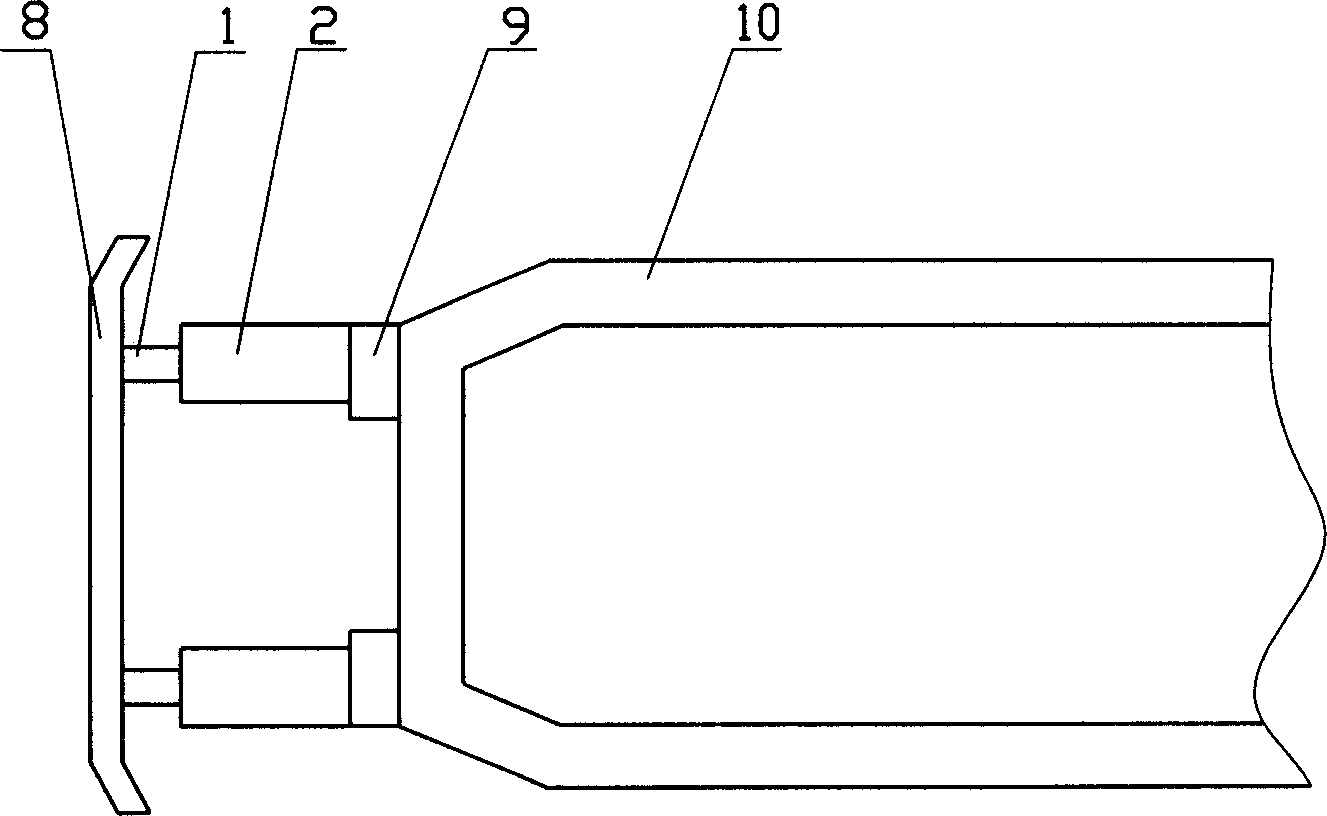

[0015] Embodiment 1: as figure 1 As shown, the automobile collision elastic buffer comprises two high-pressure oil cylinders, the piston 1 of each high-pressure oil cylinder is fixed with the bumper 8 of the automobile respectively, and each high-pressure oil cylinder 2 is then installed on the longitudinal beam 9 of the automobile frame 10 (the For installation see figure 2 ), and the oil cavity of each high-pressure oil cylinder is also communicated with the pressure storage bottle 4 through its own high-pressure oil pipe, and the oil cavity, high-pressure oil pipe and pressure storage bottle 4 are all filled with hydraulic oil to form a closed hydraulic system. Here, the pressure accumulator bottle 4 can be placed on other parts of the vehicle frame, so that the volume of the high-pressure oil cylinder can be greatly reduced, so that it can be easily installed on the front or rear of the front of the car, and at the same time it will meet the needs of the vehicle when it c...

Embodiment 2

[0022] Embodiment 2: as figure 2 As shown, it is different from the above-mentioned first embodiment in that: the pressure accumulator bottle is canceled, and the buffer is only two high-pressure oil cylinders. Similarly, the piston 1 of each high-pressure oil cylinder is fixed with the bumper 8 of the automobile respectively, and Each high-pressure oil cylinder 2 is installed on the longitudinal beam 9 of the vehicle frame 10 respectively, and the oil chamber of each high-pressure oil cylinder is filled with hydraulic oil to form a closed hydraulic chamber. In the same way, when a car collides, as long as the ratio of the moving volume of the piston to the volume of the closed hydraulic chamber conforms to the elastic deformation law of the hydraulic oil, it can become a "spring" with high stiffness. At this time, the volume of each high-pressure oil cylinder is relatively large. If the installation position at the front of the car body allows, such a high-pressure oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com