Seamless binding technology for leather product

A leather product, seamless technology, applied in the direction of composite leather, etc., can solve the problem of affecting the appearance of the overlapped place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

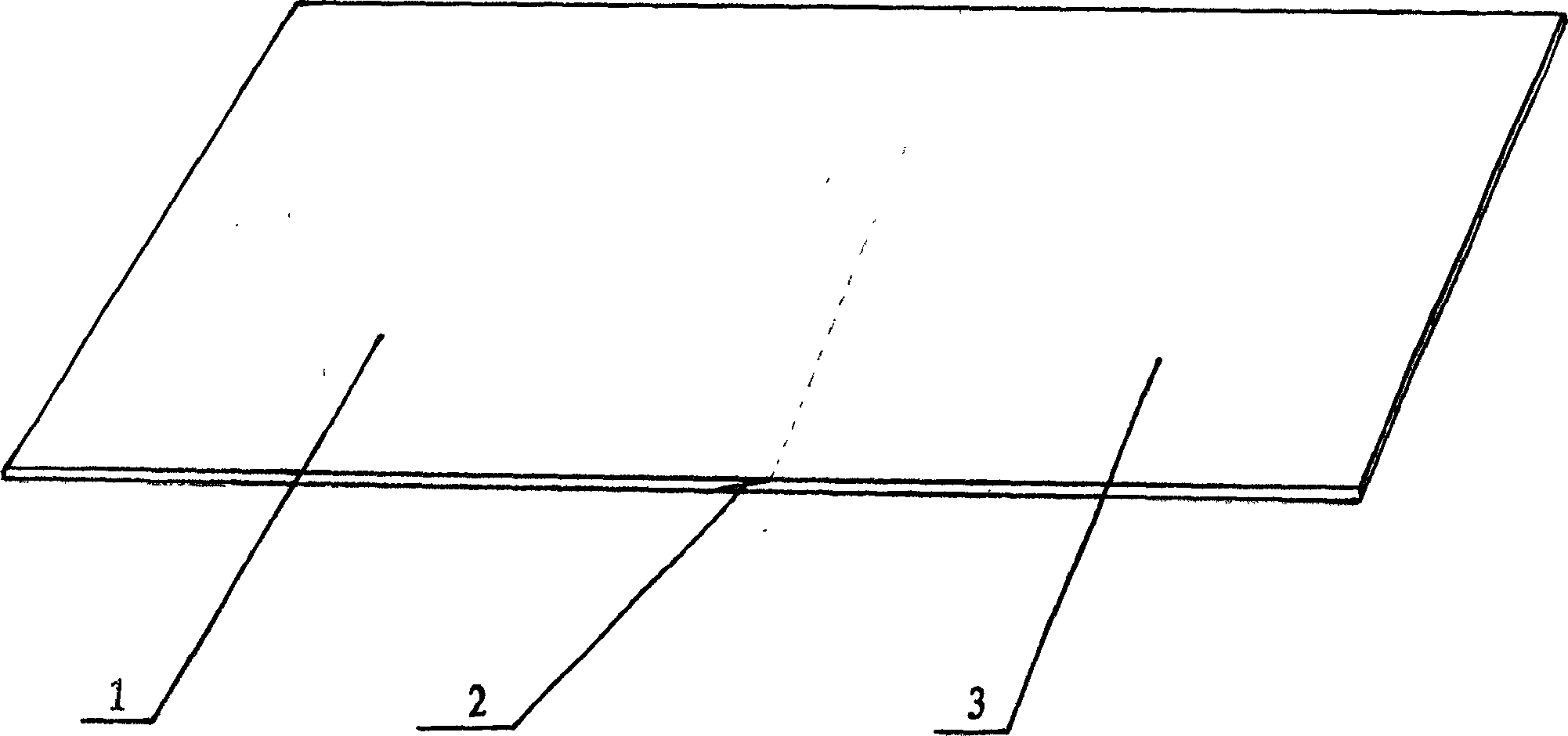

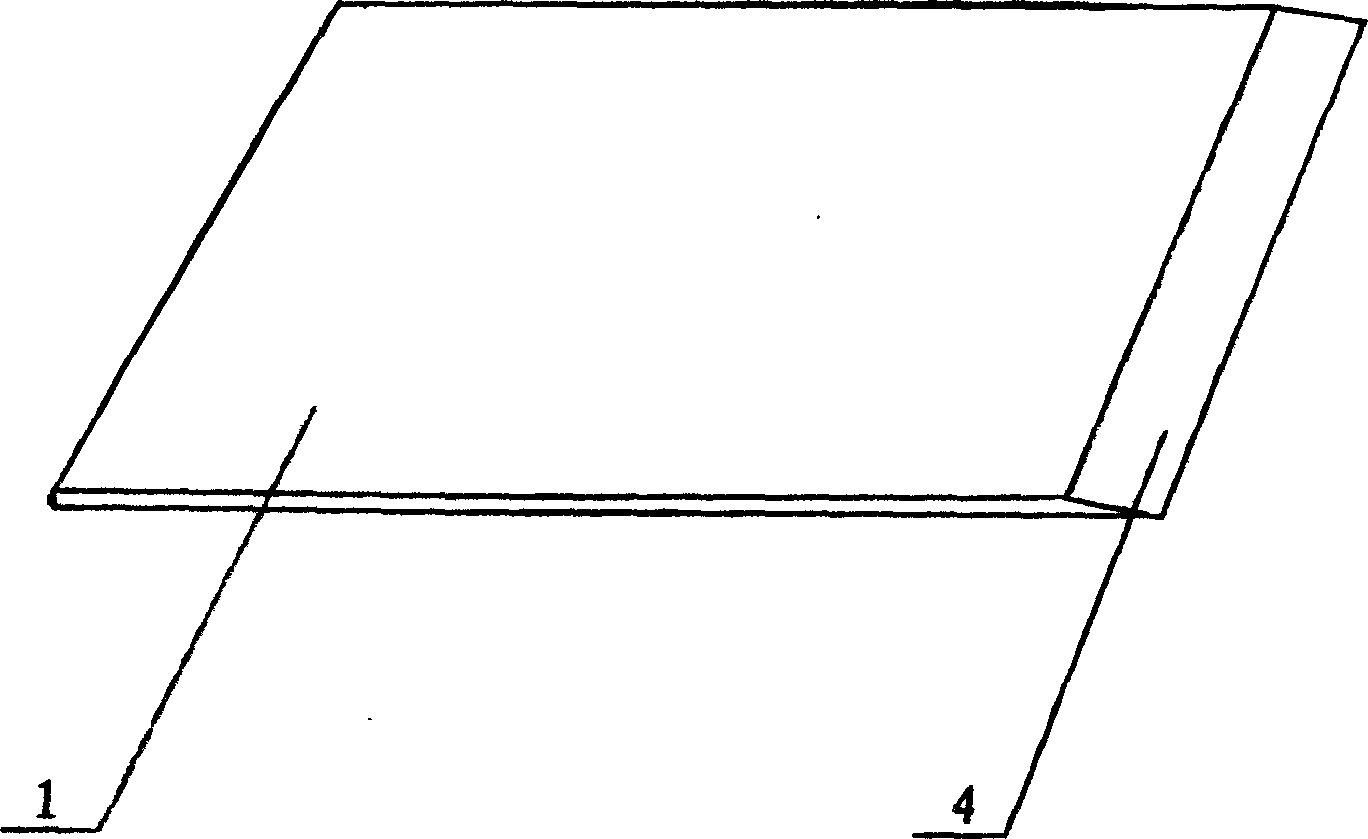

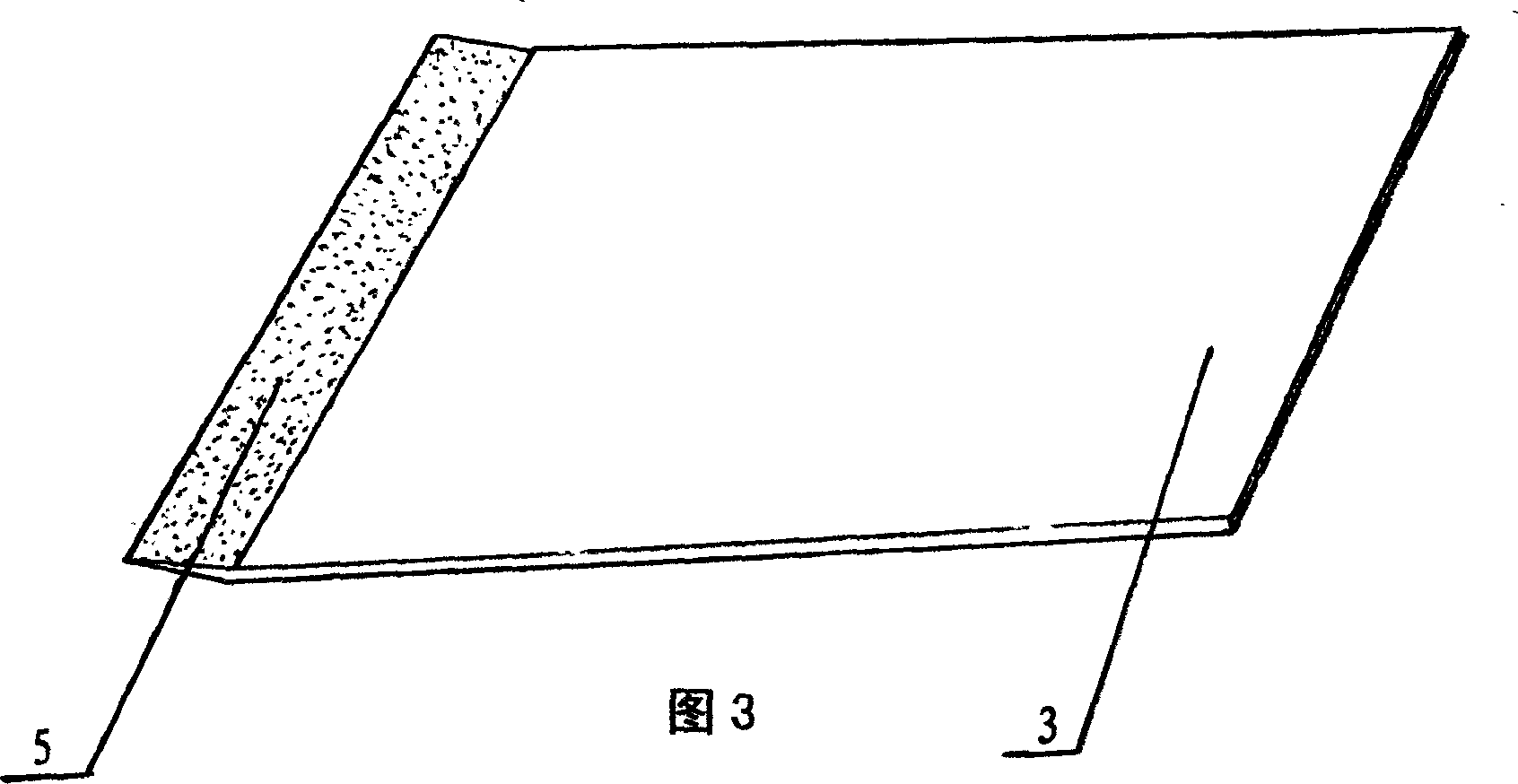

[0010] As shown in the figure, press the leather sheet 1 and the pressed leather sheet 3 on the two pieces of leather that need to be combined, and use a peeling knife to cut the meat surface of the two leathers into a slope 4 of the leather flesh surface layer, and smooth the pieces to no Thickness, the fiber width of the flesh surface of the peeled leather should be controlled at 10mm; peeling must have a slope, and the pneumatic grinding wheel is used to remove the surface coating sanding layer 5 of the pressed leather stubble, which not only achieves the purpose of removing the coating, but also does not damage the leather fibers. . Then adopt high-frequency bonding technology to bond, first apply the leather treatment agent once on the upper pressure leather slope 4 and the lower pressure leather sanding layer 5, remove oil stains and impurities, then apply the adhesive twice respectively, enter The vacuum vulcanizer is heated for 6 minutes, and the temperature is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com