Water pipe structure capable of preventing water pipe from freezing crack

A water pipe, freezing and cracking technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of hard water pipes, metal hard water pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

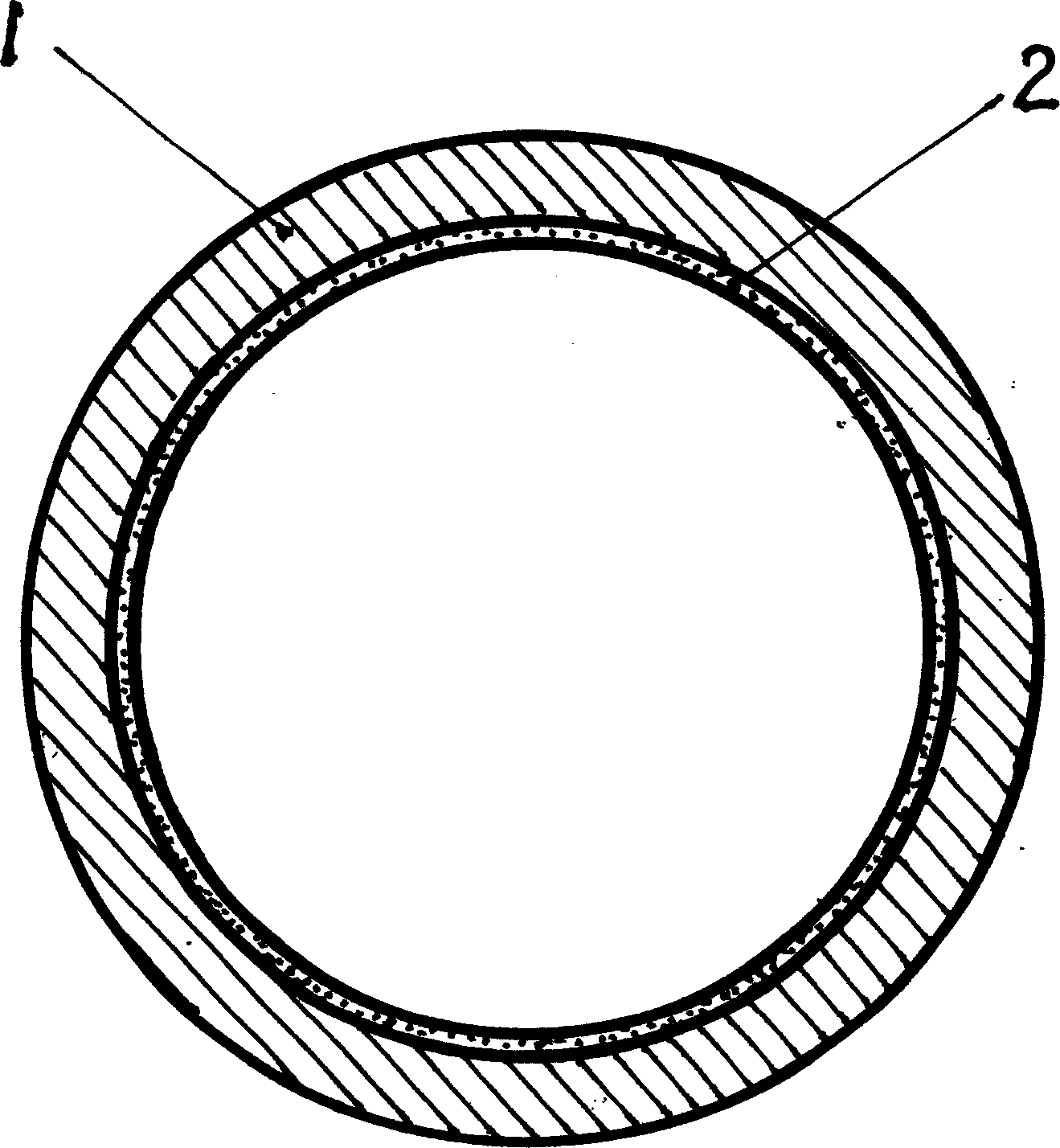

[0012] As we all know: if the volume of ice in the water pipe at 0°C is "0.92", then the volume of ice will expand to "1.00" when the temperature continues to cool down to -4°C. It can be deduced that the thickness of the non-metallic foam flexible liner 2 is approximately equal to When the internal diameter of the water pipe 1 is "0.03" times, the compressibility formed by the non-metallic foam flexible liner 2 is enough to ensure that: when the 0°C ice in the water pipe 1 continues to cool down to -4°C, although the volume of the ice expands, However, the expansion and bursting of the water pipe 1 will not be caused.

[0013] To sum up, taking a metal water pipe 1 with an inner diameter of 20 mm as an example, as long as a layer of non-metal foam flexible liner 2 with a thickness of 0.6 mm is attached to the inner wall of the pipe, when the temperature is lowered to -4°C, the metal Water pipe 1 can not be expanded and cracked by ice.

[0014] When implementing the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com