Winter anti-freezing and emergency system and method used for workshop fire hoses

A fire-fighting water pipe and emergency system technology, which is applied in the water supply pipeline system, water supply main pipeline, water supply equipment, etc., can solve the problems that the pipeline cannot be quickly filled with water, and the on-site fire can not be extinguished in time, so as to reduce fire losses and meet firefighting needs , the effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

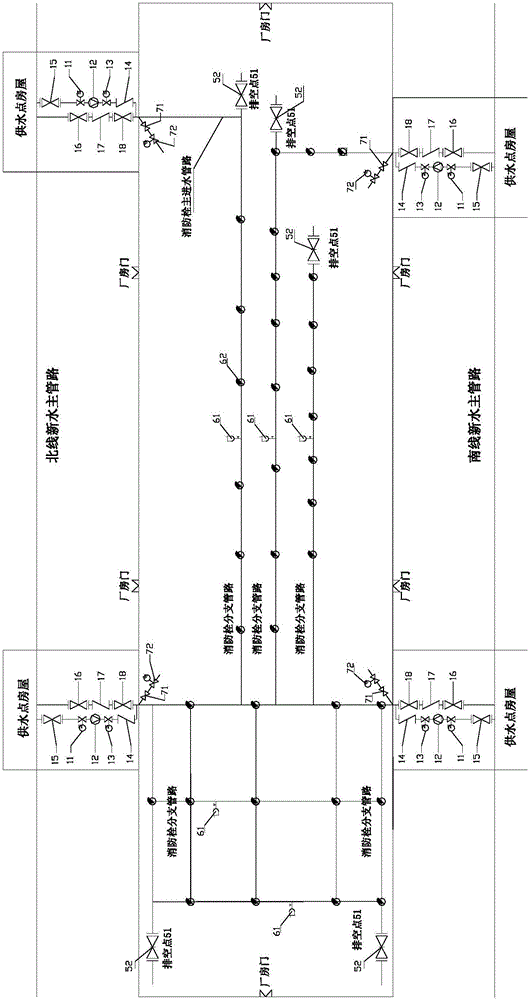

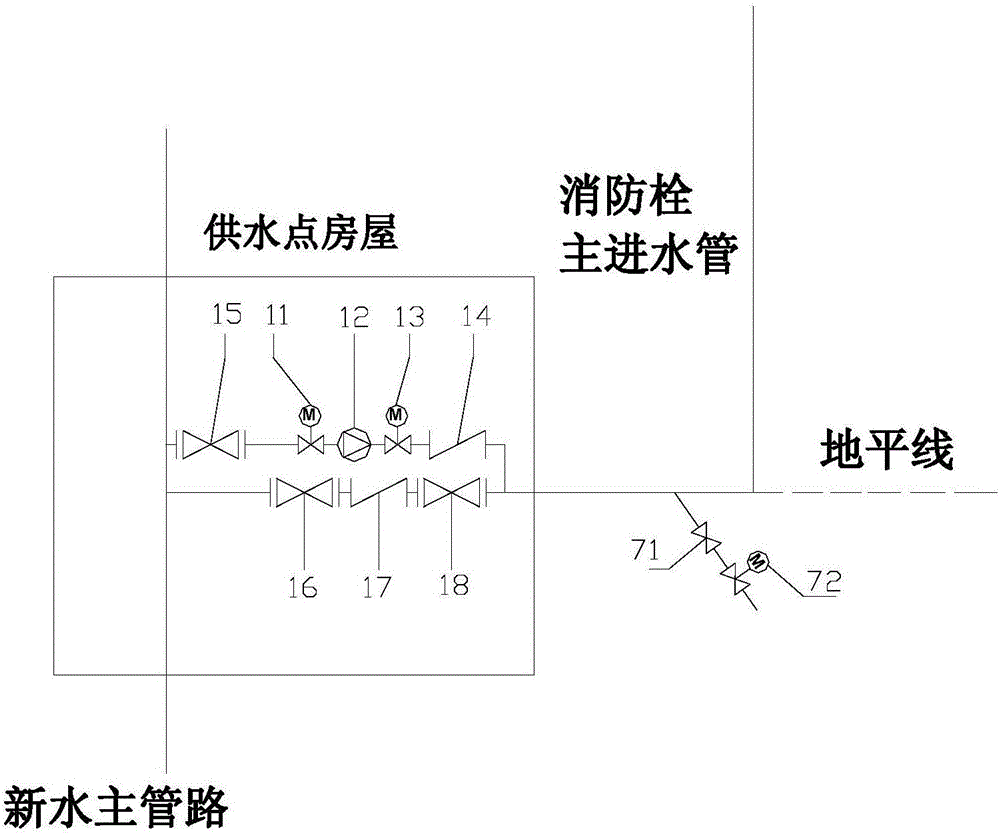

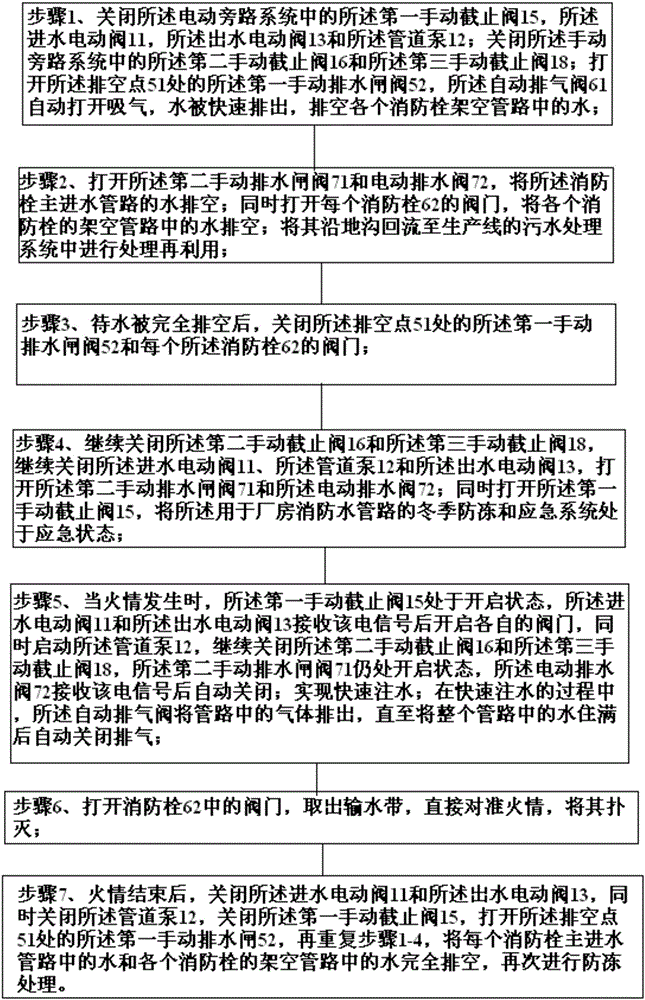

[0040] Such as figure 1 and 2 As shown, the present invention provides a winter antifreeze and emergency system for the fire water pipeline of a factory building, and the system is respectively installed in four water supply point houses, and the system includes: a manual bypass system and an electric bypass system; The manual bypass system and the electric bypass system are respectively connected between the south and north new water main pipelines and the main water inlet pipeline of the fire hydrant, and are parallel to each other; the electric bypass system further includes: a first manual shut-off valve 15 , water inlet electric valve 11, pipeline pump 12, water outlet electric valve 13, first check valve 14; the manual bypass system further includes: second manual stop valve 16, second check valve 17, third manual Shut-off valve 18; the first manual s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com