Broadband power vibration damper for automobile rear axle

A dynamic shock absorber and wide-band technology, applied to springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve the problems of narrow effective vibration damping frequency range and inability to meet the needs of automobile vibration damping , to achieve the effect of compact structure and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

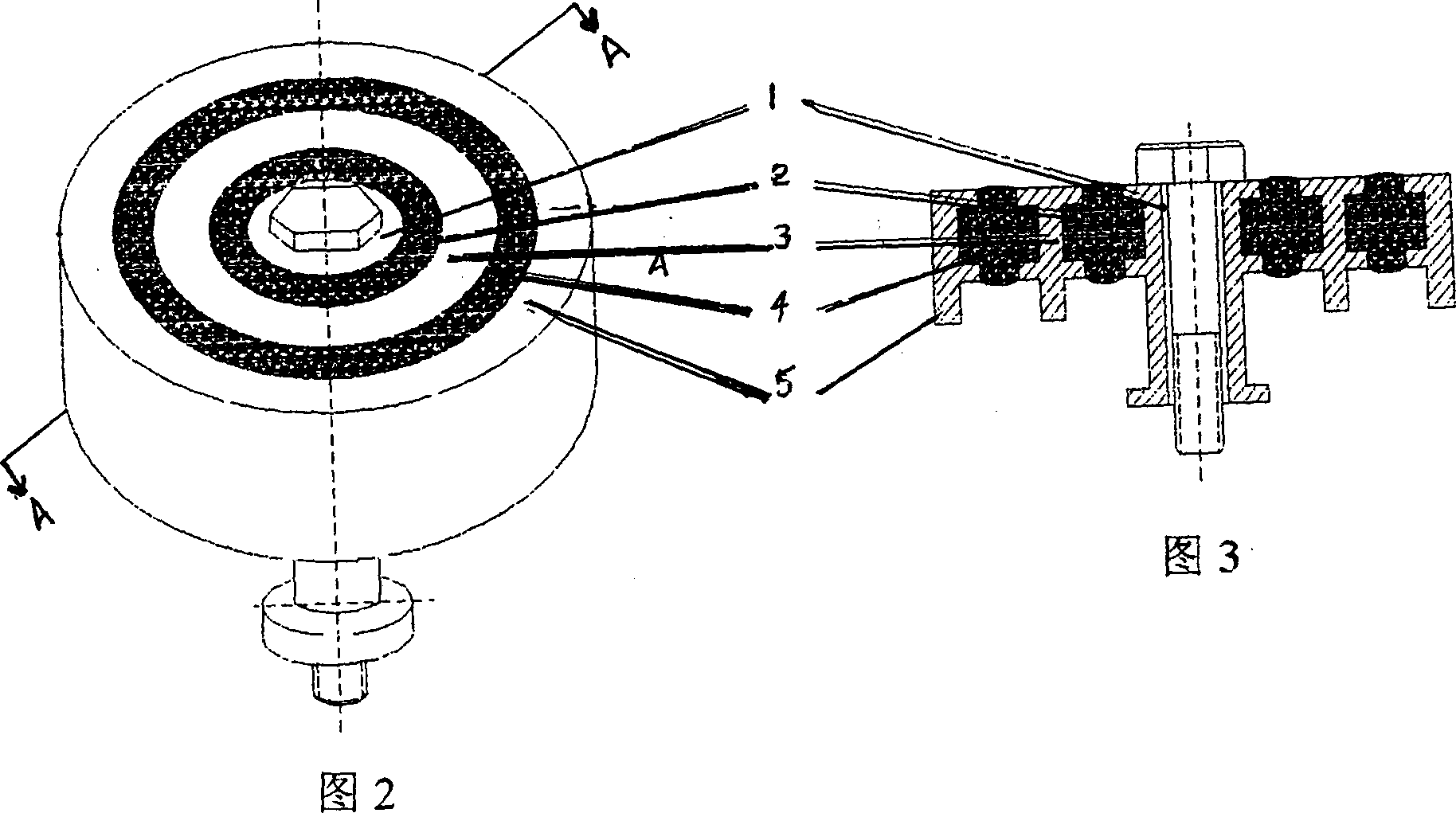

[0014] Referring to accompanying drawings 2 and 3, the wide-band dynamic shock absorber for the automobile rear axle includes a central mounting block 1, a rubber spring ring 2 is set outside the central mounting block 1, and an annular mass block is set outside the rubber spring ring 2 3; Similarly, a rubber spring ring 4 and an annular mass block 5 are set on the outer side of the annular mass block 3, and so on, and rubber spring rings 2, 4 and annular mass blocks 3 are sequentially set on the outer side of the central mounting block 1 , 5, forming a multi-degree-of-freedom dynamic damping unit.

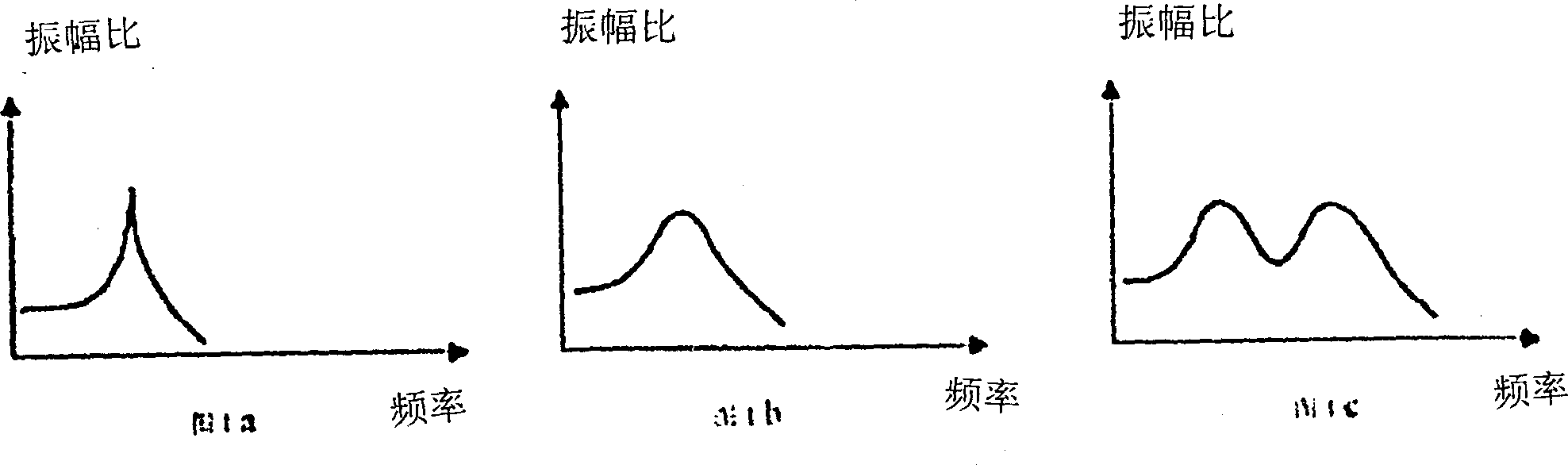

[0015] The design method of the wide-band dynamic shock absorber for the rear axle of the automobile is exactly the same as that of the general multi-degree-of-freedom dynamic shock absorber with damping: according to the frequency range of the vibration of the rear axle of the automobile, the amplitude of the vibration force and the size of the allowable vibration, determine Reas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com