Prompting mechanism for deflection of sawing machine and saw-band

A technology of band sawing machine and sawing belt, which is applied in the direction of sawing machine device, attachment device of sawing machine, metal sawing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

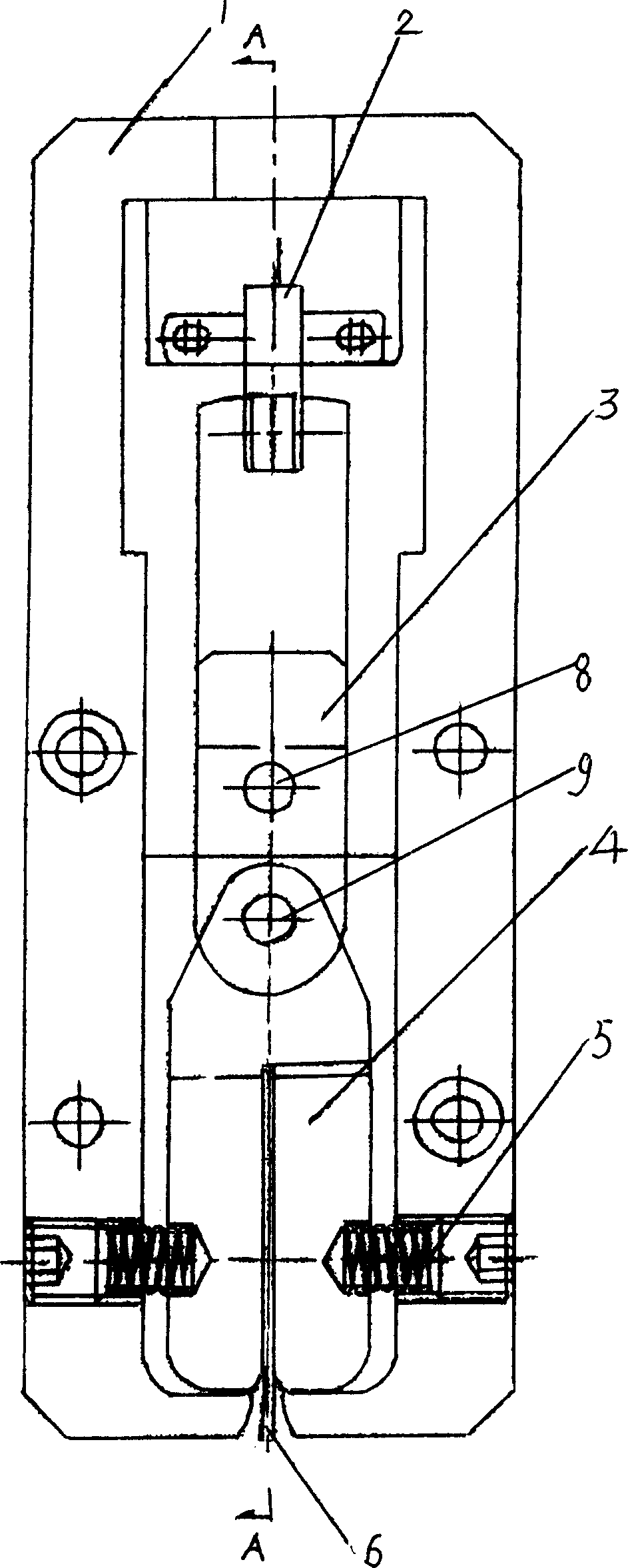

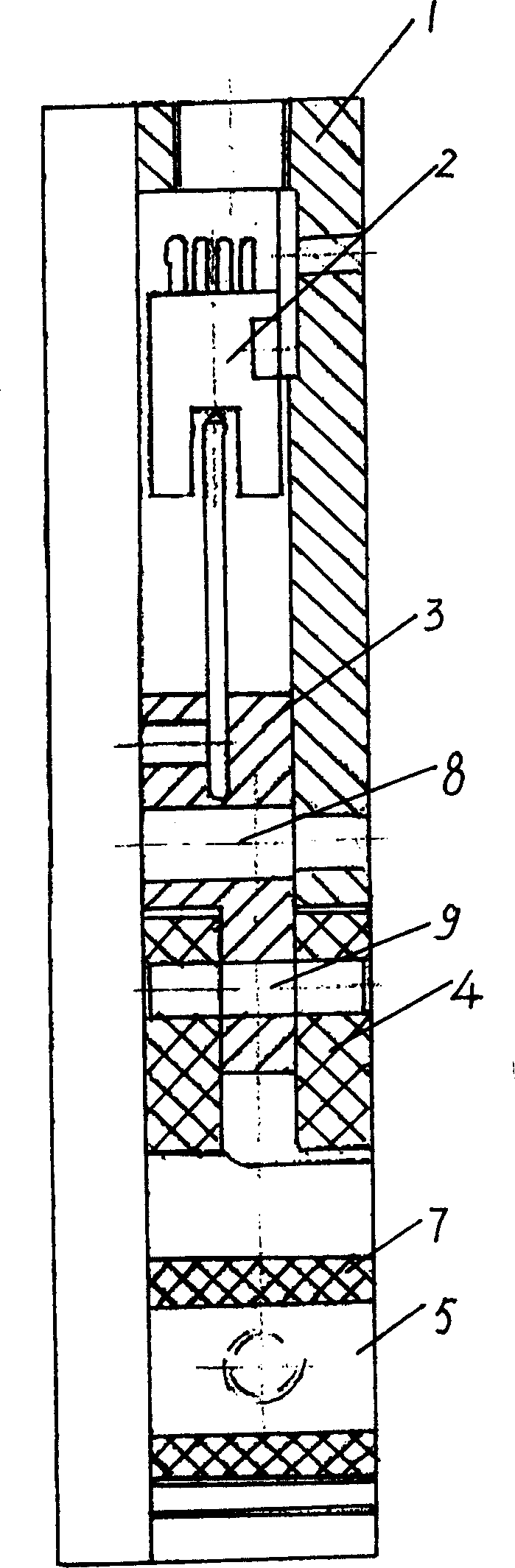

[0010] see figure 1 with figure 2 , a band sawing machine saw band deflection prompting mechanism, it has a shell 1 that can be fixed on the band sawing machine saw band bracket, and has a pair of symmetrical sensing splints that can keep close contact with both sides of the saw band 6 4. The upper part of the housing 1 is fixed with a photoelectric sensor 2, and the middle part has a pin shaft-8 pin with a sensor arm 3. The sensor arm 3 can swing left and right according to the pin shaft. Connected to the sensing arm 3 , a spring 5 is embedded in the lower part of the casing 1 left and right, and the other end of the spring 5 withstands the sensing splint 4 .

[0011] see figure 2 The surface where the sensing splint 4 and the saw band 6 are kept in close contact is embedded with wear-resistant strips 7, which can improve the service life of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com