Fuel injection valve

A technology of fuel injection and fuel oil, which is applied in the direction of fuel injection devices, engine components, machines/engines, etc., and can solve the problems of no fuel cavity and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

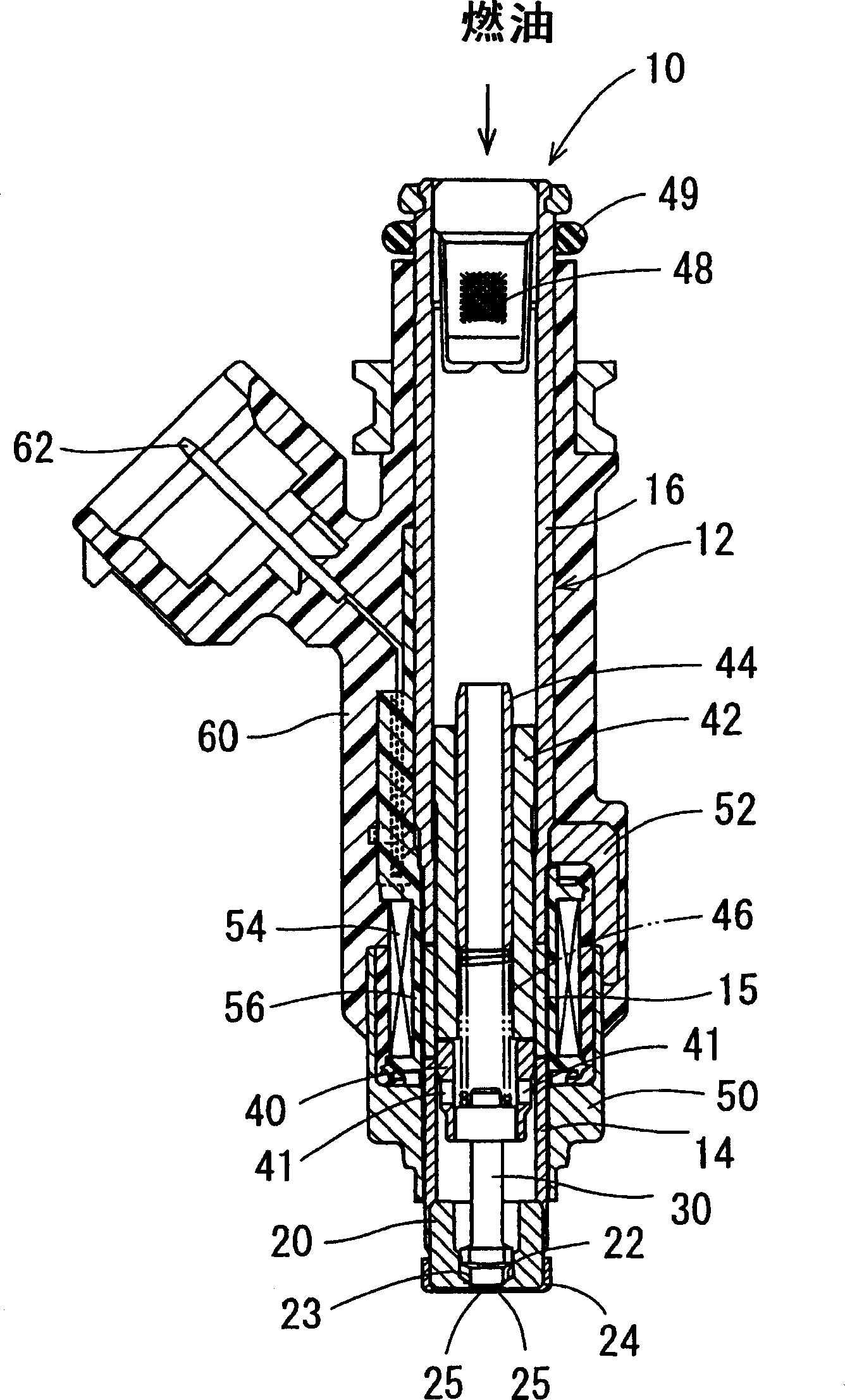

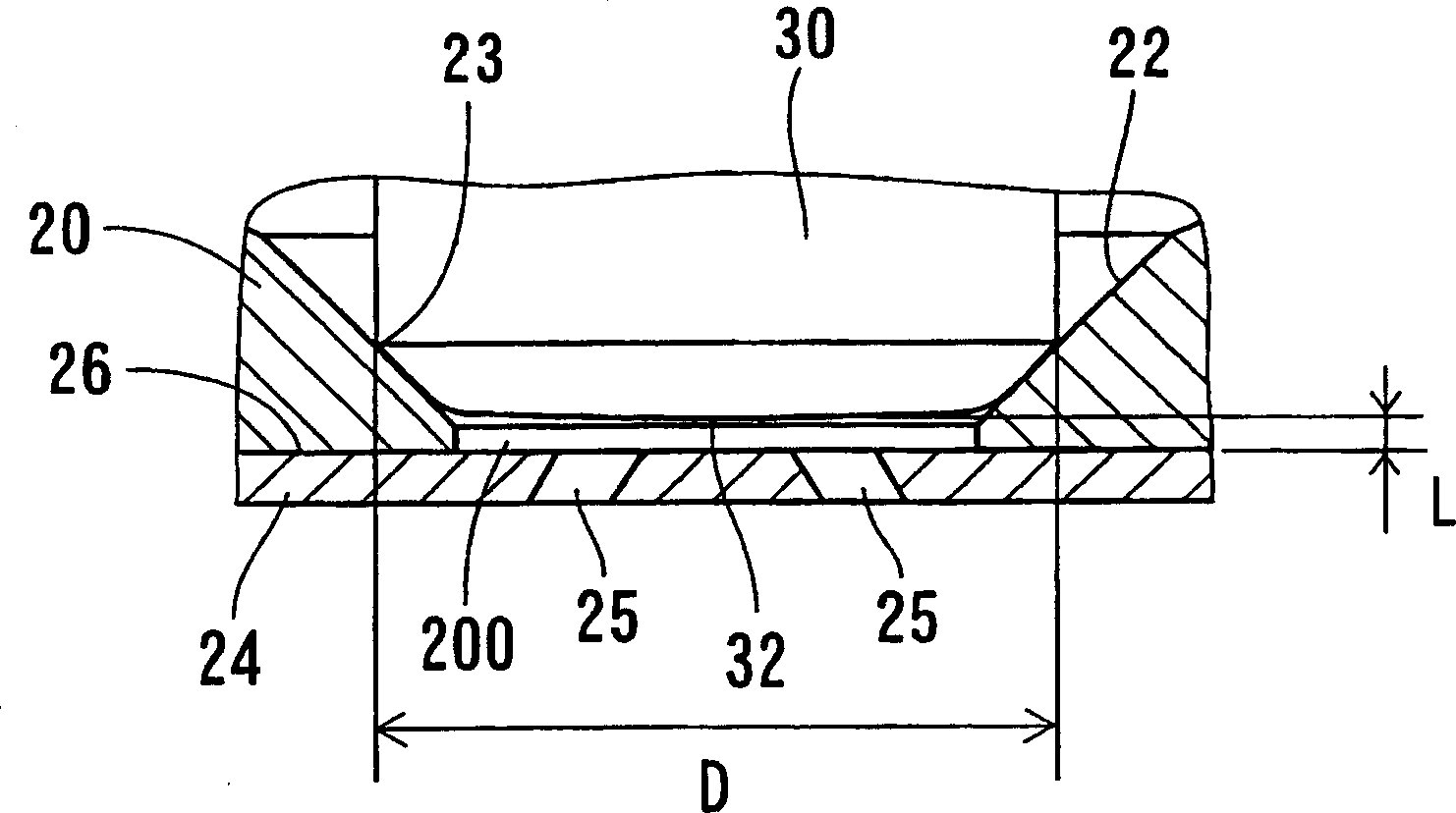

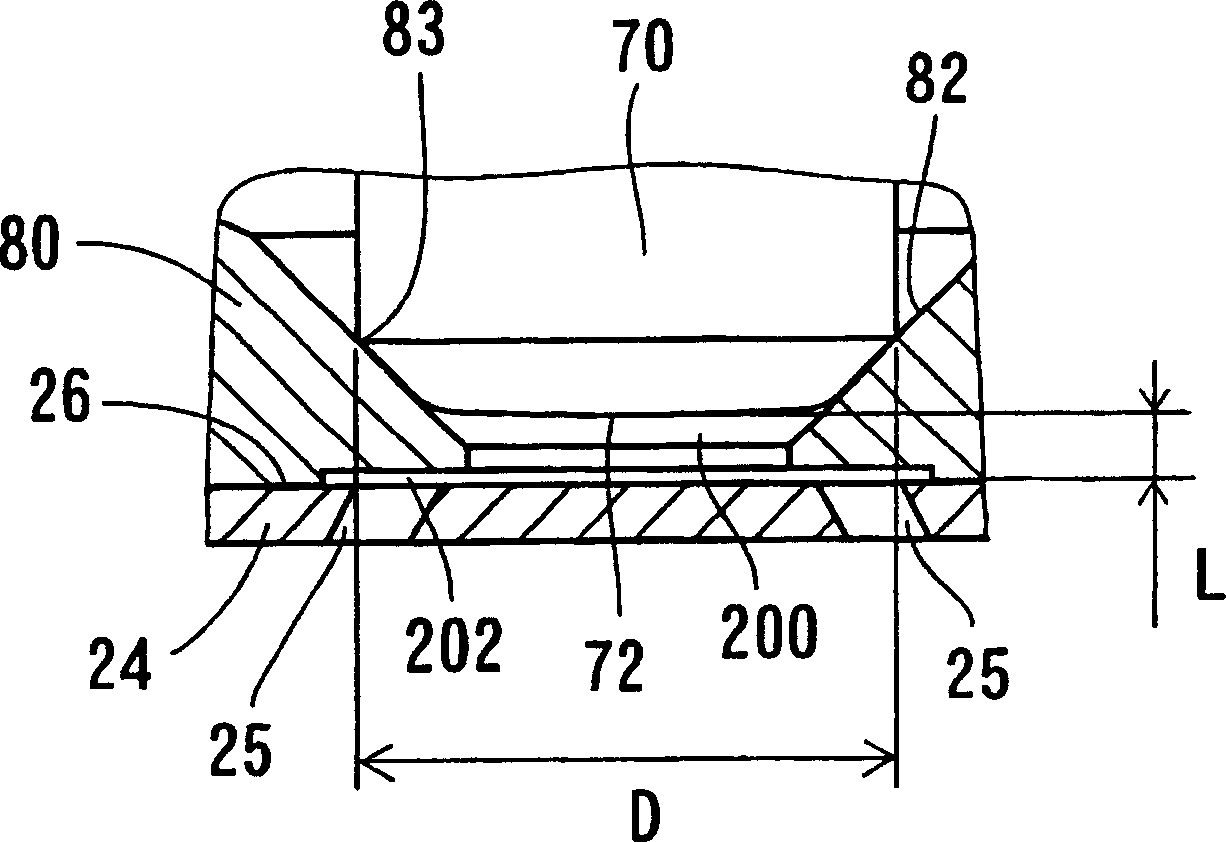

[0019] refer to figure 1 , shows a fuel injection valve according to a first embodiment of the present invention. The fuel injection valve 10 according to this embodiment is applied to an air-cooled engine of a two-wheeled vehicle having an engine displacement of 150 cc or less. The fuel injection valve 10 is located in an intake pipe connected to a combustion chamber of a gasoline engine to inject fuel into intake air flowing through an intake passage defined by the intake pipe. The fuel injection valve 10 is applicable to a direct-injection gasoline engine, which directly injects fuel into a combustion chamber of the gasoline engine. The fuel injection valve 10 is also applicable to diesel engines. The static injection quantity (static injection quantity) of the fuel injection valve 10 is set so that: when the fuel pressure is 300kPa and n-heptane (n-heptane) is used, the static injection quantity becomes 150cm 3 / min or below. In the fuel injection valve 10, the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com