Mixing system

A technology of mixing systems and mixing elements, applied in the field of mixing systems, can solve problems such as pressure drop, and achieve the effect of high adaptability and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

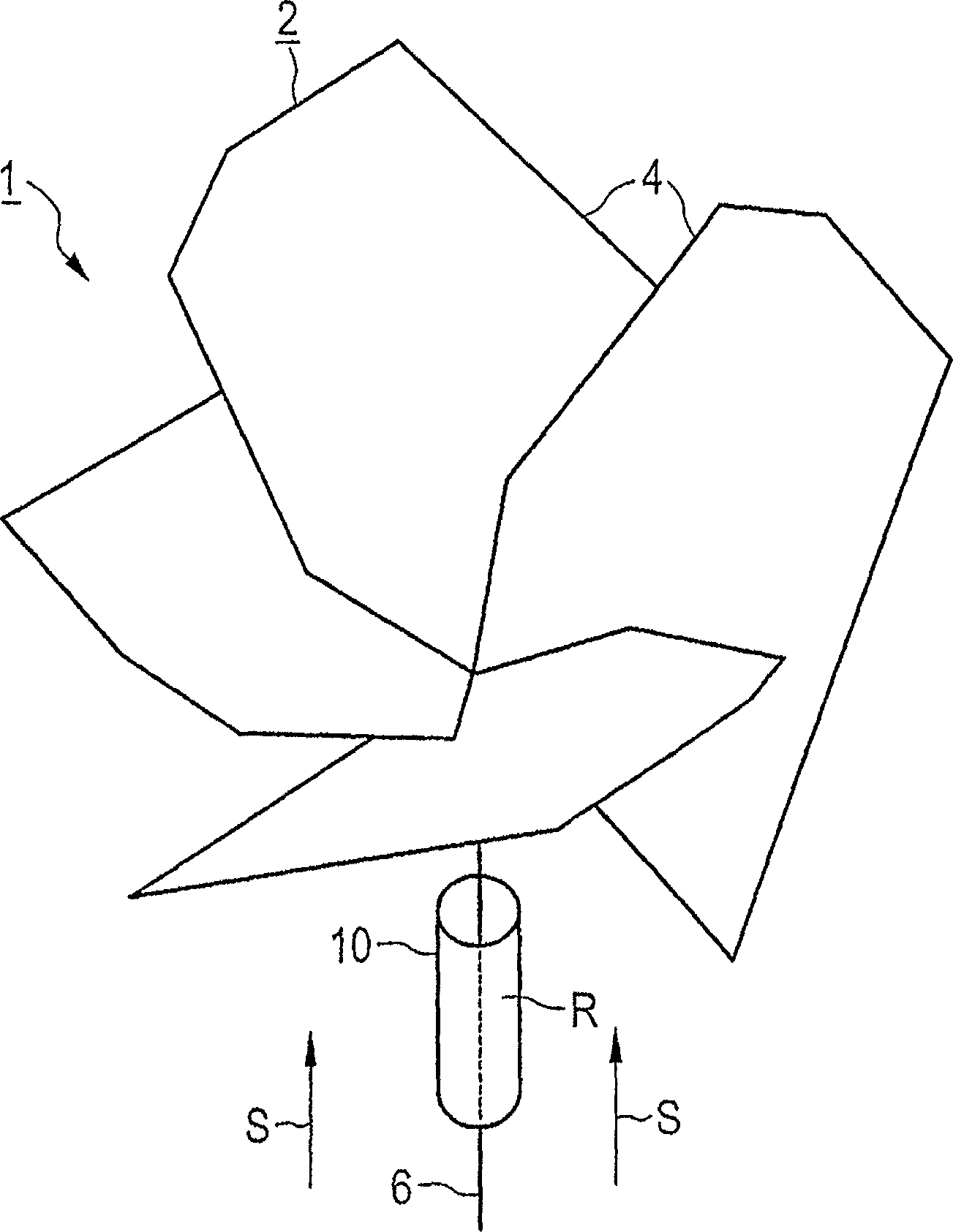

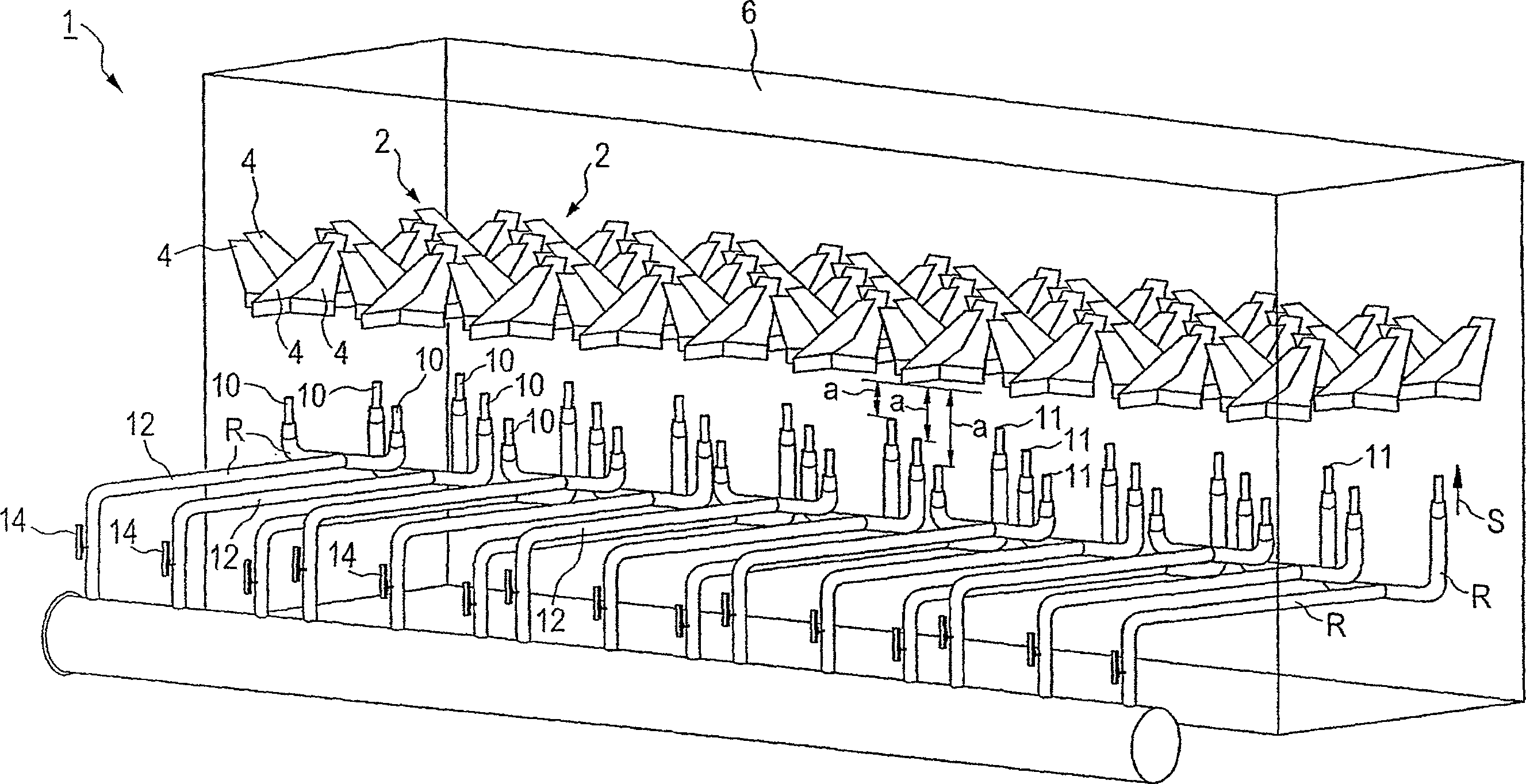

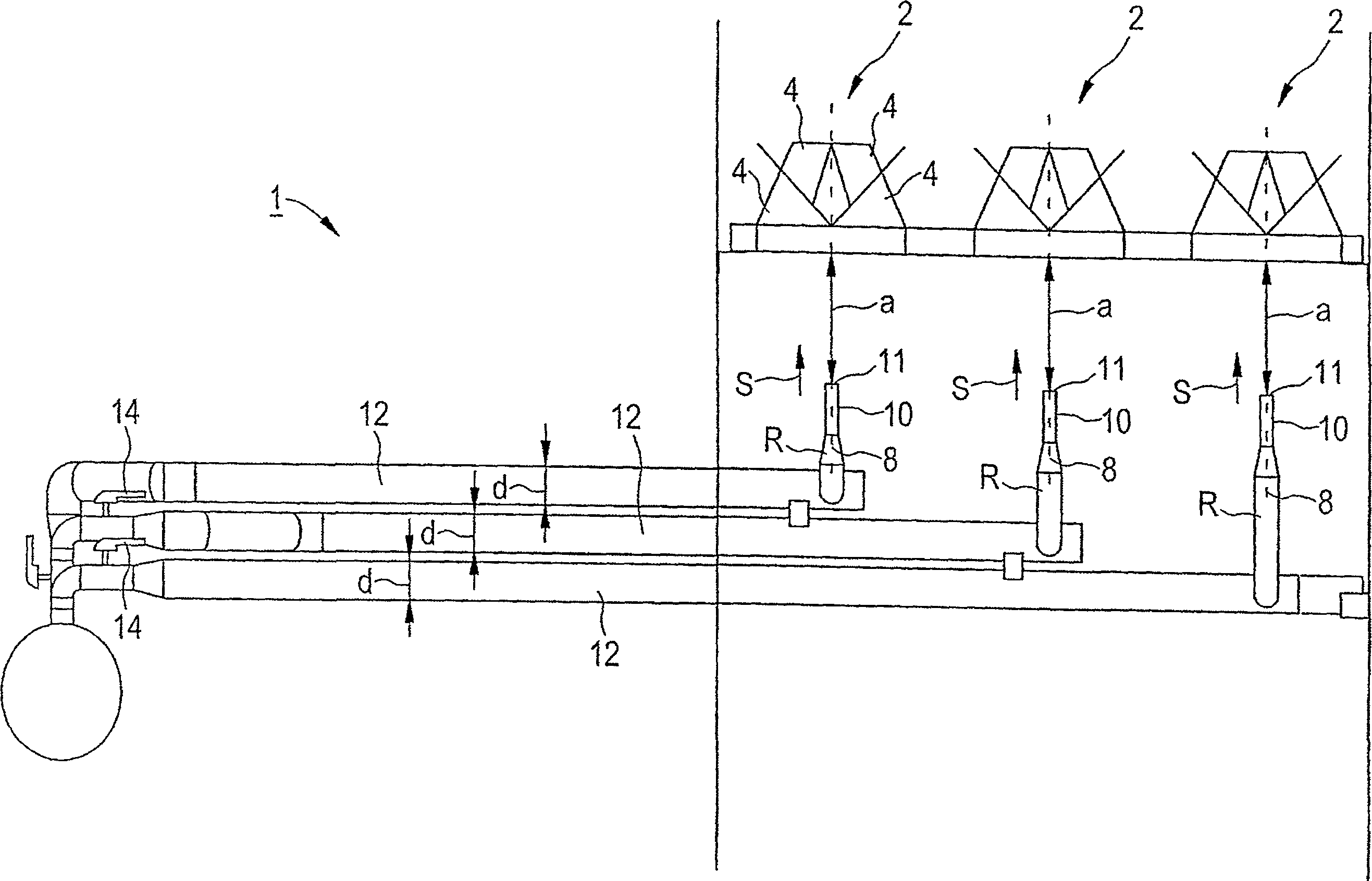

[0032] exist Figure 1 to Figure 3 The mixing system 1 shown in includes a plurality of mixing elements 2 arranged in the form of a fence in the assembly surface, in figure 1 Only one mixing element 2 is shown in the image 3 Three mixing elements 2 are shown in . In the exemplary embodiment, the mixing element 2 consists of four inclined mixing blades 4 which are arranged around the central axis 6 of the mixing element 2 . The mixing blades 4 serve to generate a vortex of the flow medium S conducted in the flow line 6 upstream of the mixing element 2 . In this way the vortex passes through the mixing blade 4 formed in the figure 2 The axial deflection of the flow duct 6 shown in and the flow medium S flowing parallel to the center axis 8 are formed in the tangential direction of the flow duct 6 and homogenize the flow medium. In order to achieve a stable mixing effect, the mixing blades 4 are arranged with one another at a constant staggered angle. In an embodiment this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap