Dual-ring sealing washer and its mfg. method

A manufacturing method and ring sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as accidents, losses, and loss of sealing performance, and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

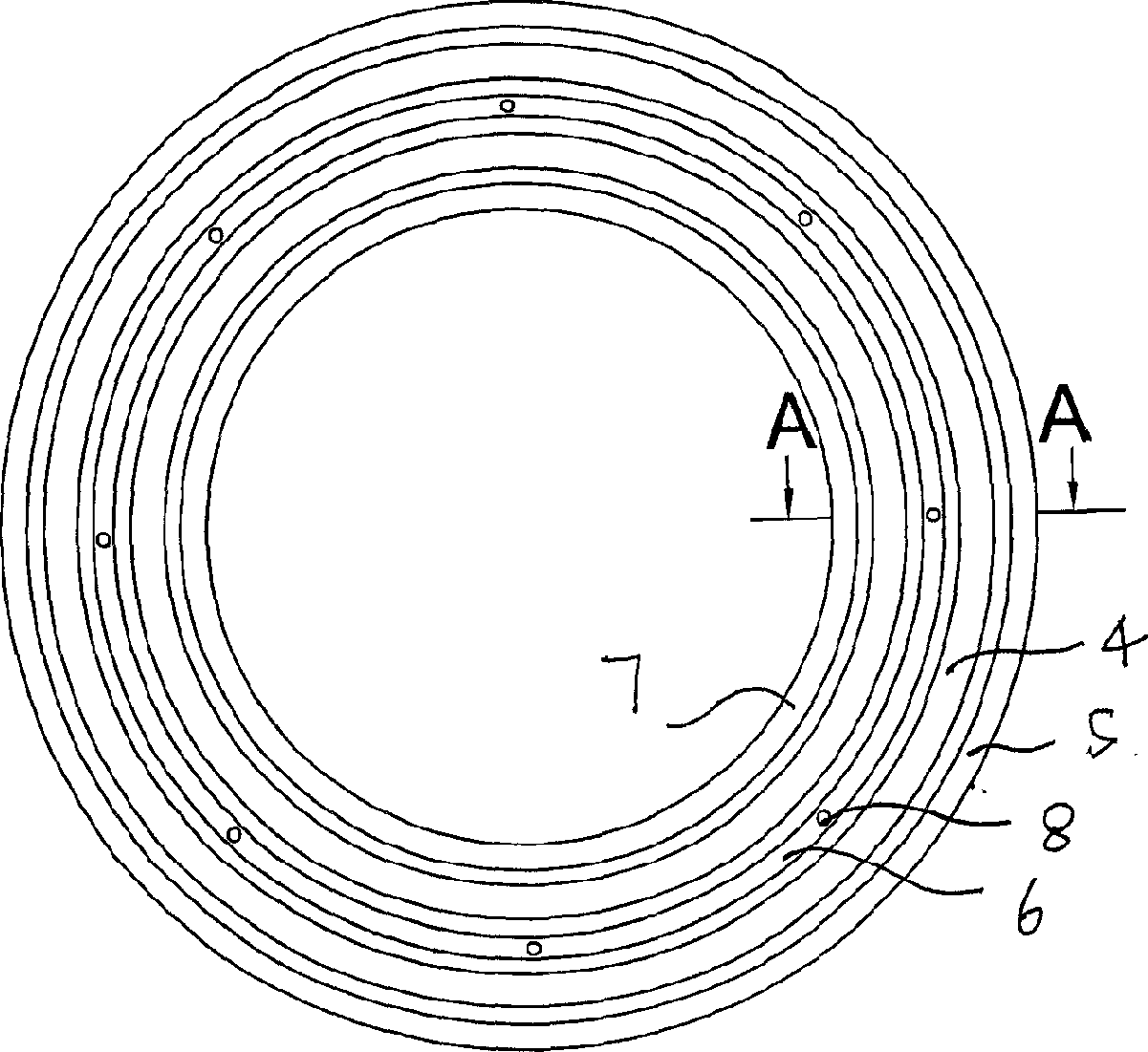

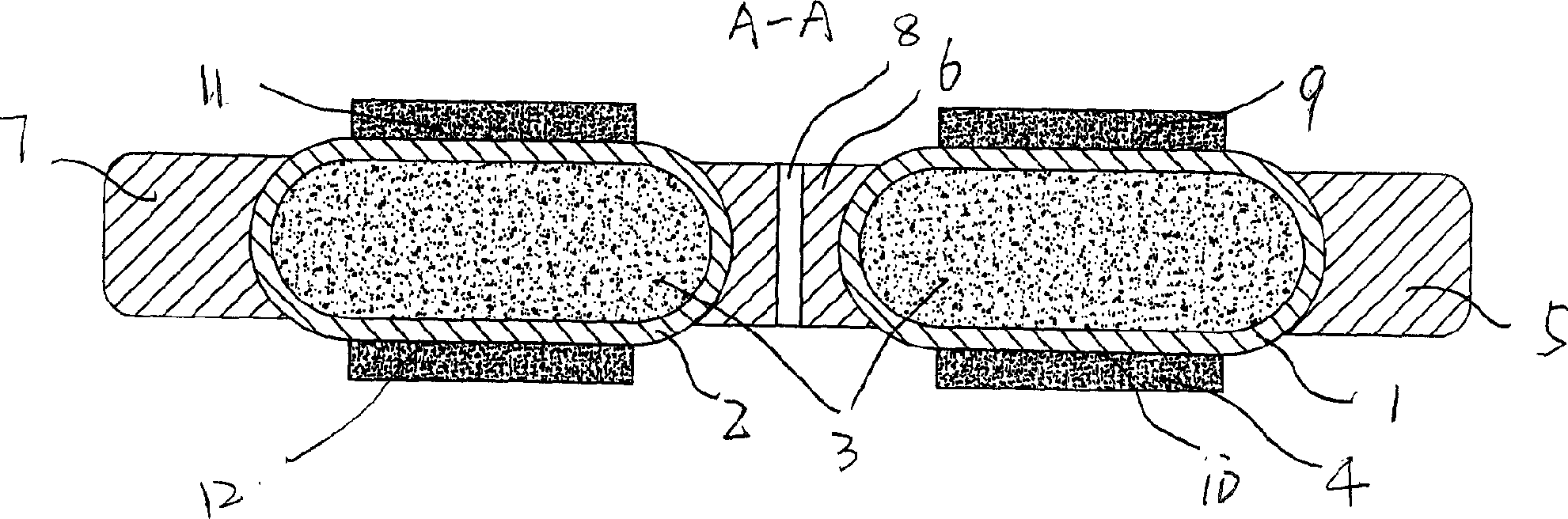

[0022] See attached figure 1 to attach figure 2 , a double-ring sealing gasket, including an annular outer metal tube 1, an annular inner metal tube 2 concentrically arranged with the outer metal tube 1, and filling in the inner chambers of the outer metal tube 1 and the inner metal tube 2 respectively The flexible sealing filler 3, the restricting middle ring 6 located between the outer metal tube 1 and the inner metal tube 2, the cladding 4 covering the upper and lower surfaces of the outer metal tube 1 and the inner metal tube 2 respectively, the outer metal tube 1 is provided with Restricting the outer ring 5, the inside of the inner metal pipe 2 is provided with a restricting inner ring 7, the outer metal pipe 1 is clamped between the restricting outer ring 5 and the restricting middle ring 6, and the inner metal pipe 2 is clamped between the restricting middle ring 6 and the restricting inner ring 7 Among them, the outer metal pipe 1, the inner metal pipe 2, the restri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com