Processing technology for extracting oil from metamorphic rock high pour point oil of burial hill by using combustion drive in horizontal well

A process technology and a technology for metamorphic rock, which are applied to the field of oil production using horizontal wells in fire-flooding metamorphic rock buried hill high-point oil reservoirs, can solve the problems of difficult control of heating temperature, difficult mining technology, complicated downhole process, etc., and achieve a long-term stable combustion state , the effect of expanding geological reserves and increasing recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

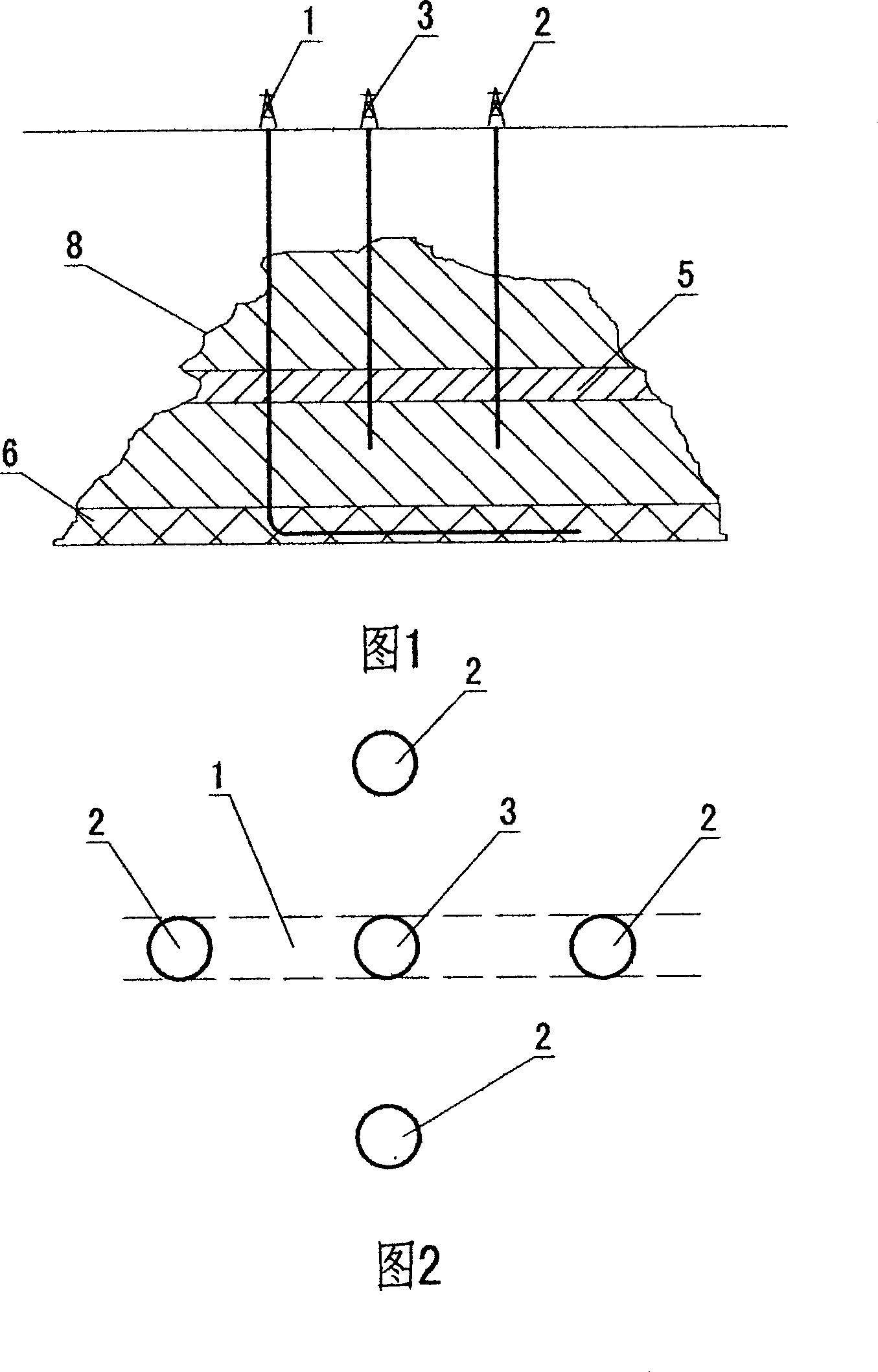

[0041] In Figure 1, the distribution of high pour point oil in metamorphic buried hills is described in the figure. Before fire flooding oil, it is necessary to clearly understand the physical parameters of the internal structural mechanism of buried hills through geological data, that is, the lithology of buried hills is metamorphic rocks, shallow-grained Migmatites, shallow grained rocks, etc., and distinguish the distribution zones of the rock surface, such as weathered zones, fracture development zones, and low-angle horizontal zones. In the distribution area of high pour point oil, generally speaking, the ground temperature above 1000 meters in buried hill rocks is less than 45 degrees Celsius, which is called immovable oil zone 5, and the interval between 1300 and 1400 meters, where the ground temperature is about 53 degrees Celsius, is the movable oil zone 6. When deploying wells, the well pattern should be deployed in the movable oil zone 6. At the same time, the oil ...

Embodiment 2

[0043]Determine the horizontal production well 1 well position according to the geological data in embodiment 1:

[0044] The horizontal oil production well 1 is selected in the formation dip angle and the vertical micro-fracture development section, and the direction of the horizontal well section should be perpendicular to the direction of the rock fractures, so as to maximize the oil drainage area through the formation fractures.

[0045] The oil well is deep and located at a position with a ground temperature above 45 degrees Celsius. The high pour point oil at this position is in a state of natural flow in the movable oil zone 6 of the formation.

[0046] In the stratum development zone, the fracture dip angle is less than 30 degrees, which is the best horizontal well location area.

Embodiment 3

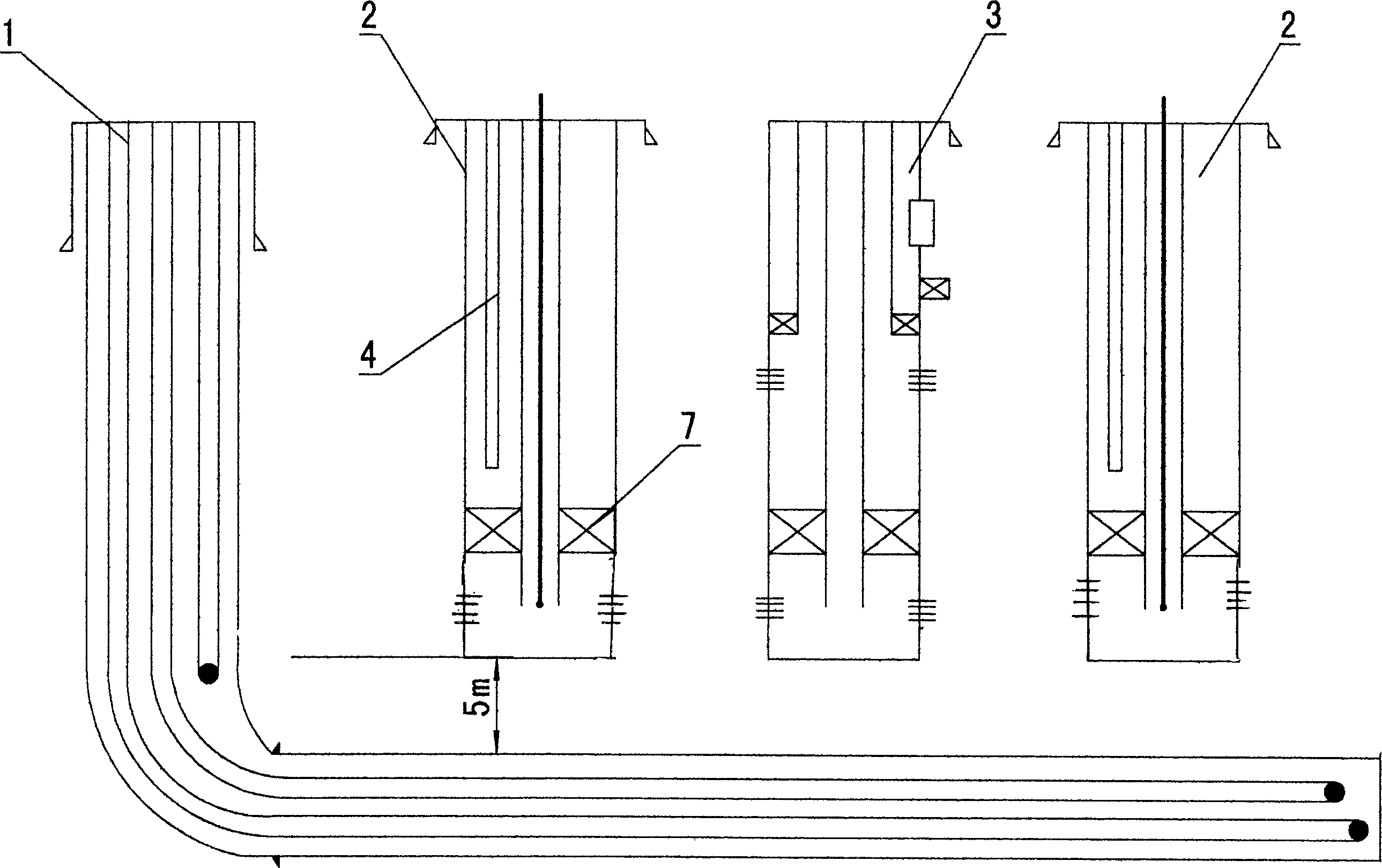

[0048] Determination of ignition wells for fire flooding (Fig. 2):

[0049] When the high pour point oil in fire-flooded metamorphic rock buried hill horizontal well 1 produces oil, in addition to drilling horizontal well 1 to produce oil, it is also necessary to drill air injection well 3 and gas production well 2 above the horizontal section of the horizontal well. Air is injected into well 3, and gas production well 2 is ventilated to form a thermal field to heat up the high pour point oil, and then it is in a stable flow state. During oil production, it is produced from oil production horizontal well 1 ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com