Double-chamber blown bottle and method for manufacturing the same

A production method and cavity technology, applied in the direction of the bottle, etc., can solve the problems that the production cannot be realized and the use effect is not produced, and achieve the effects of convenient production and processing, reasonable structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

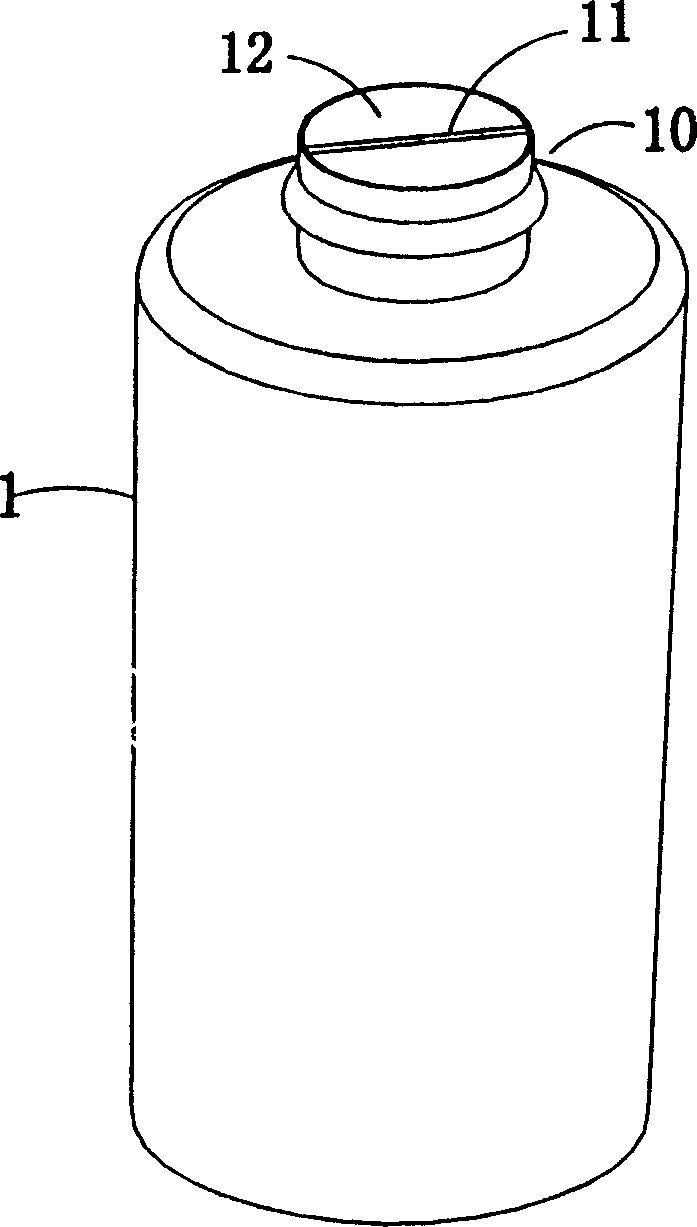

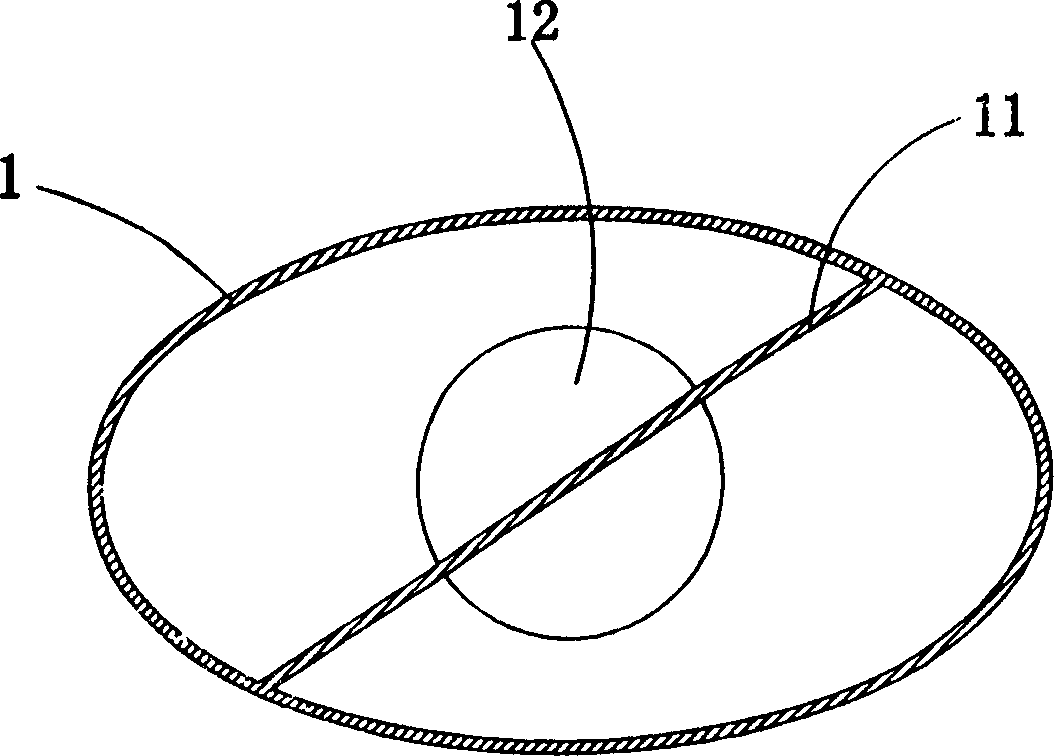

[0017] See figure 1 , 2, the bottle body 1 made by the present invention is integrally formed with a partition 11, the partition 11 separates the inner cavity and opening 12 of the bottle body 1 into two parts isolated from each other. The partitions 11 are arranged vertically. After adopting this structure, the bottle body 1 of the present invention has two independent cavities, and different products can be respectively placed without interference.

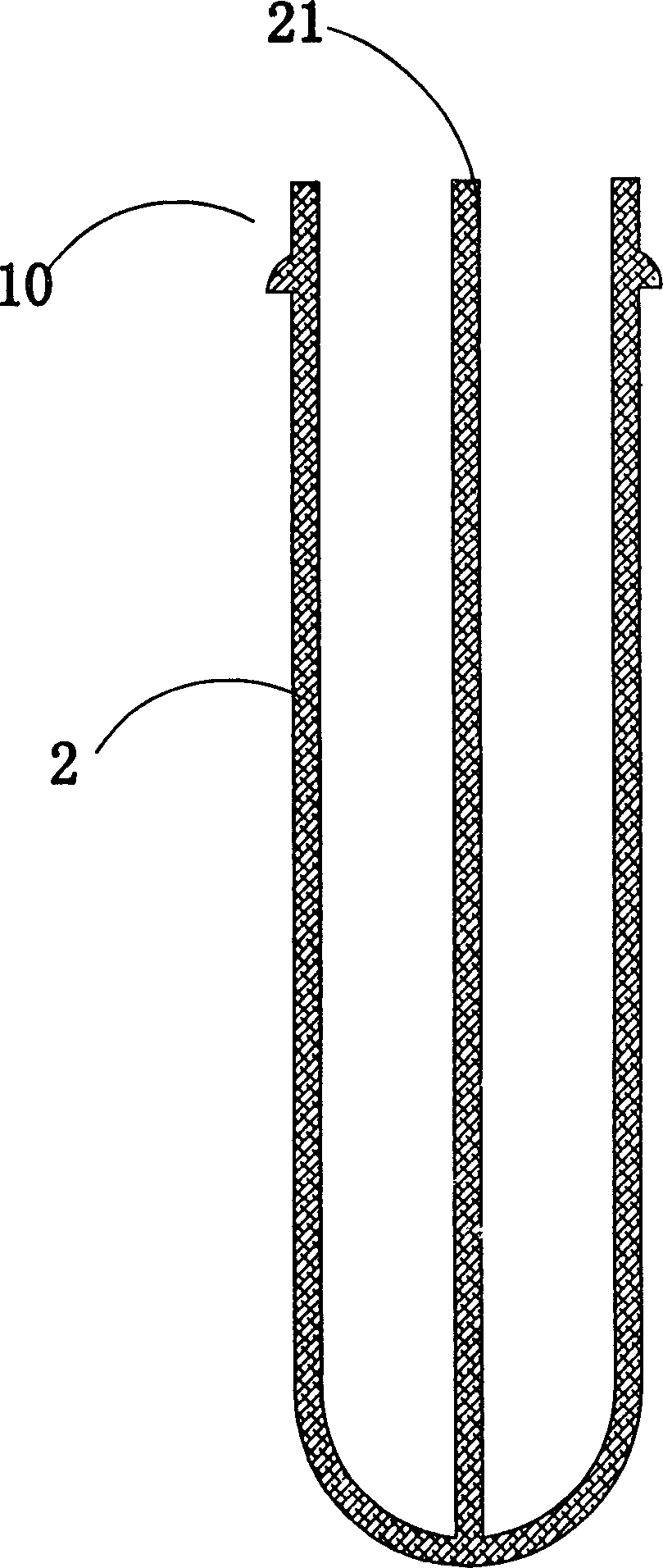

[0018] When making the present invention, the first step is to make double empty test tube bottle base 2.

[0019] See image 3 , the injection molded double-empty test tube preform 2 is internally formed with a combined tube wall 21, and the combined tube wall 21 separates the inner cavity and opening of the double-empty test tube preform 2 into two parts that are isolated from each other. The combined tube wall 21 forms the partition 11 in the bottle body 1 after blow molding. The opening 10 of the bottle body 1 is directl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap