Super thin composite decorating board and its fixing method onto wall

A fixing method and decorative panel technology, applied in covering/lining, construction, building construction, etc., can solve the problems of waste of resources, low safety performance, easy to fall off, etc., and achieve convenient installation and assembly, wide range of use, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A fixing method between an ultra-thin composite decorative board and a wall, comprising:

[0045] a. Dragon skeleton preparation step: used to fix the dragon skeleton on the wall surface;

[0046] b. Preparatory steps for the decorative board: it is used to fix and paste the fixing board on the back of the panel, and make the protruding part of the fixing board protrude from the side of the panel;

[0047] c. The first installation step: used to fix the protruding part to the keel frame;

[0048] d. The second installation step: it is used to align the recessed part of another decorative board with the protruding part of the fixed decorative board, so that the panel side of the fixed decorative board is aligned with the panel side of the other decorative board Lean, and fix the protruding portion of the other decorative plate to the keel frame.

[0049] Trim panel preparation steps include: It includes:

[0050] Panel preparation step: used to process the panel;

[...

Embodiment 2

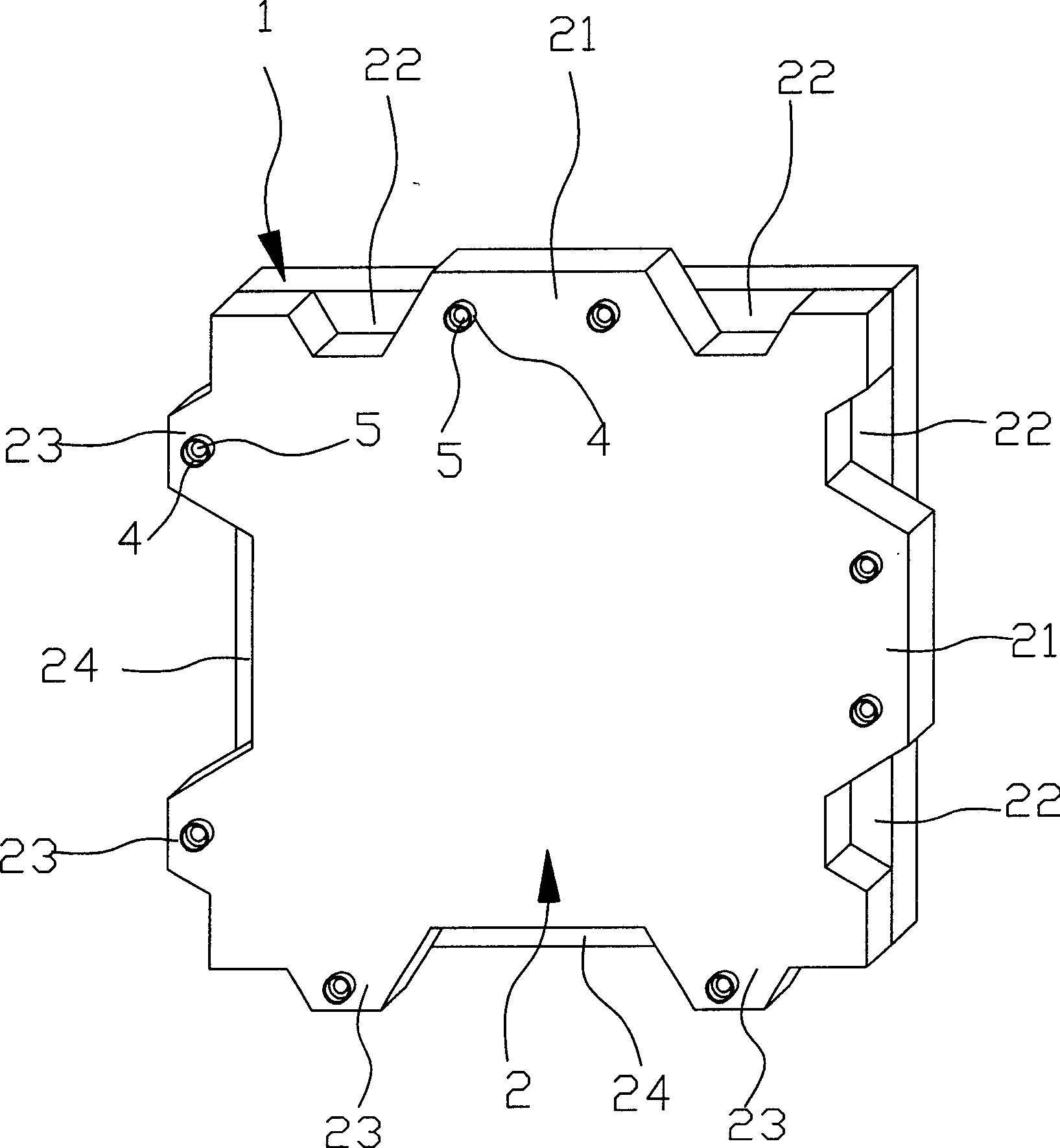

[0056] An ultra-thin composite board, such as figure 1 , 2, including a panel 1, a fixed plate 2, eight positioning columns 3, eight washers 4.

[0057] The panel 1 is a stone plate with a thickness of 3mm-6mm. The stone slab is a marble stone slab or a granite stone slab. This embodiment takes stone slabs as an example, but is not limited to stone slabs. Others such as ceramic tiles, mosaics, or aluminum-plastic panels are also applicable to this technical solution.

[0058] The fixing plate 2 is fixedly attached to the lower surface of the main body layer of the panel 1 . In the four sides of fixed plate 2. The first side is opposite to the third side, and the second side is opposite to the fourth side; both the first side and the second side have a first protruding part 21 and a concavity protruding from the side of the panel 1 Two second recessed portions 22 on the side of the panel 1; the third side and the fourth side both have two second protruding portions 23 protr...

Embodiment 3

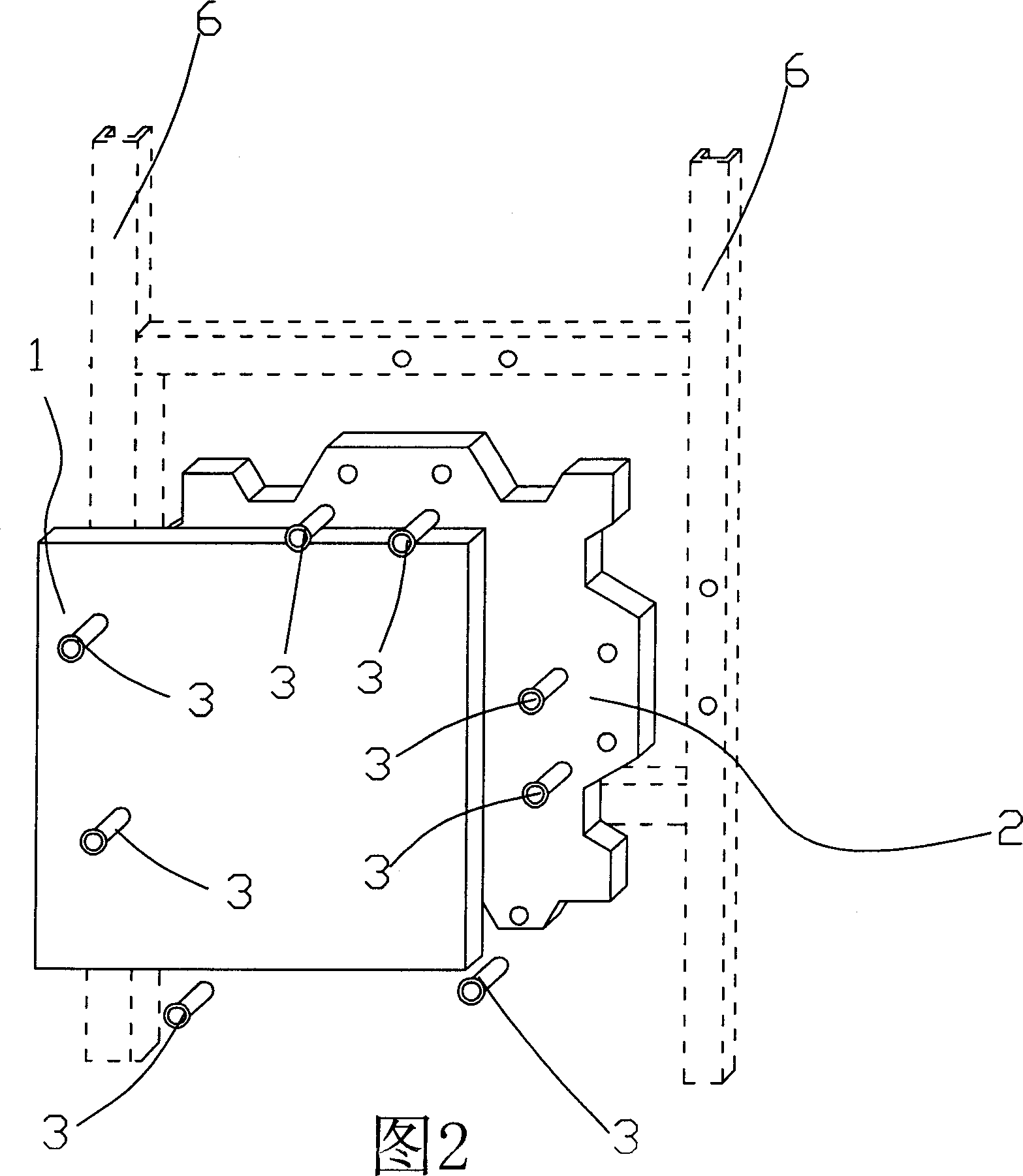

[0065] A fixing device between an ultra-thin composite decorative board and a wall, comprising:

[0066] Several decorative panels: its structure is as described in Embodiment 1;

[0067] Several dragon skeletons: they are fixed and attached to the wall surface;

[0068] several screws or bolts;

[0069] The fixing plate 2 is attached to the keel frame 6 , and the screw 3 passes through the positioning through hole 5 of the fixing plate 2 and is fixedly screwed on the keel frame 6 . The keel frame 6 generally includes several main angle steel columns and transverse angle steel columns fixedly connected between the two general angle steel columns. Or it also includes a vertical angle steel column fixedly connected between two horizontal angle steel columns.

[0070] For two adjacent decorative boards, the protruding part of one decorative board is inserted into the recessed part of the other decorative board.

[0071] When splicing the ultra-thin composite stone plate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com