Dispenser having rotary actuator assembly

A dispenser and actuator technology, applied to engine components, valve operation/release devices, valve details, etc., to solve problems such as dispensing interruptions, dynamic seal wear, and loose seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

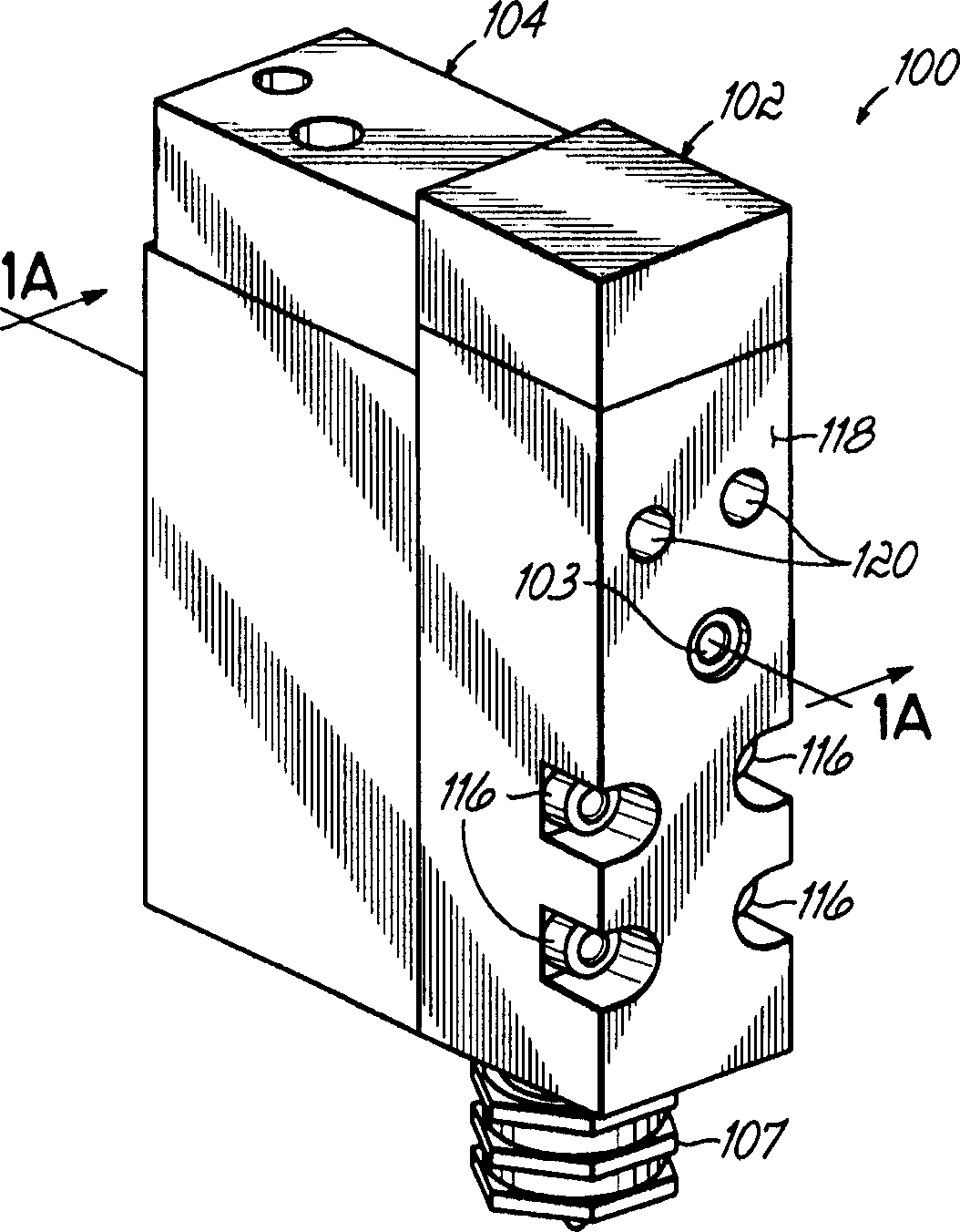

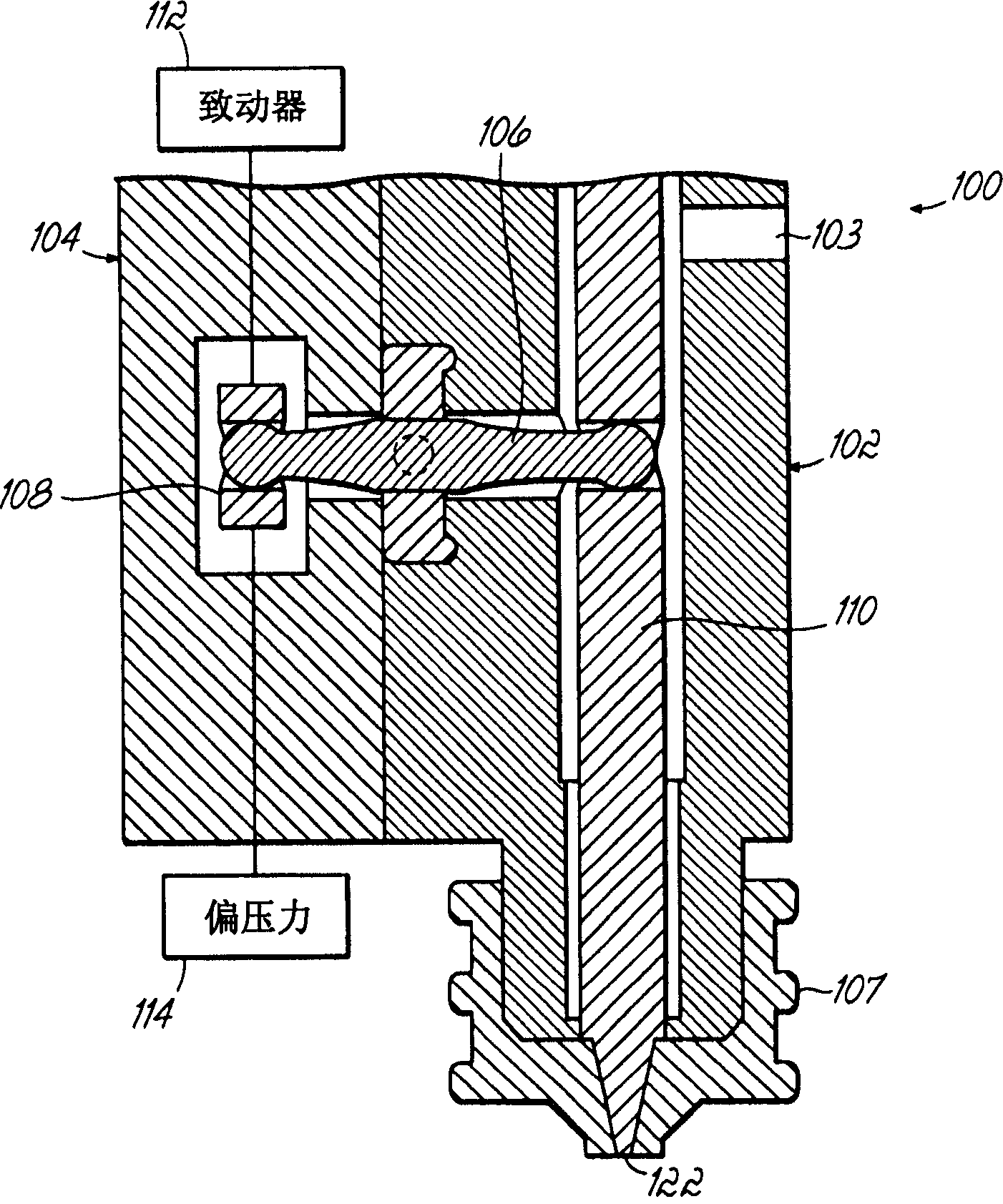

[0030] figure 1 is a schematic illustration of an example dispenser according to the invention. Unlike existing dispensers, the dispenser of the present invention includes a hydraulic section 102 and an actuating section 104 arranged side by side rather than vertically. Since the hydraulic section 102 is often connected to a heated manifold or other heated components, this side-by-side arrangement thermally isolates the actuating section 104 from such heated components. As a result, the O-rings and other seals in the actuating portion 104 are not exposed to high temperatures as in prior art dispensers. Also, other electrical components such as solenoids are not exposed to high temperatures. This allows the solenoid to be coupled closer to the actuating portion, reducing response time. Overall, this side-by-side arrangement will enhance reliability and performance relative to traditional vertically arranged dispensers.

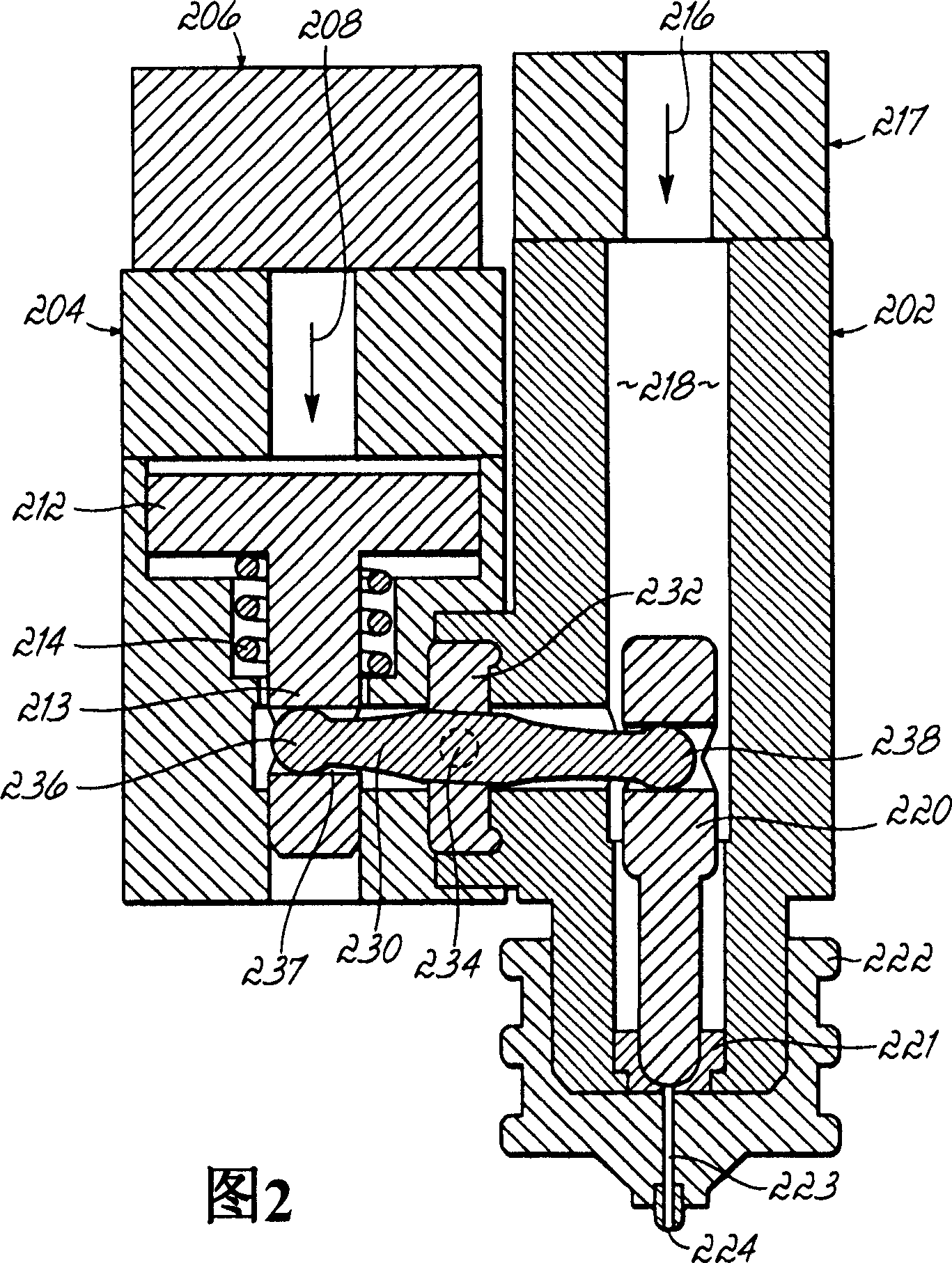

[0031] Such as Figure 1A , an example dispenser acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com