Heat resisting and pressure resisting safe electric detonator for oil well

A safe electrical and voltage-resistant technology, applied in the field of blasting, can solve problems such as the inability to meet the safety requirements of electric detonators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

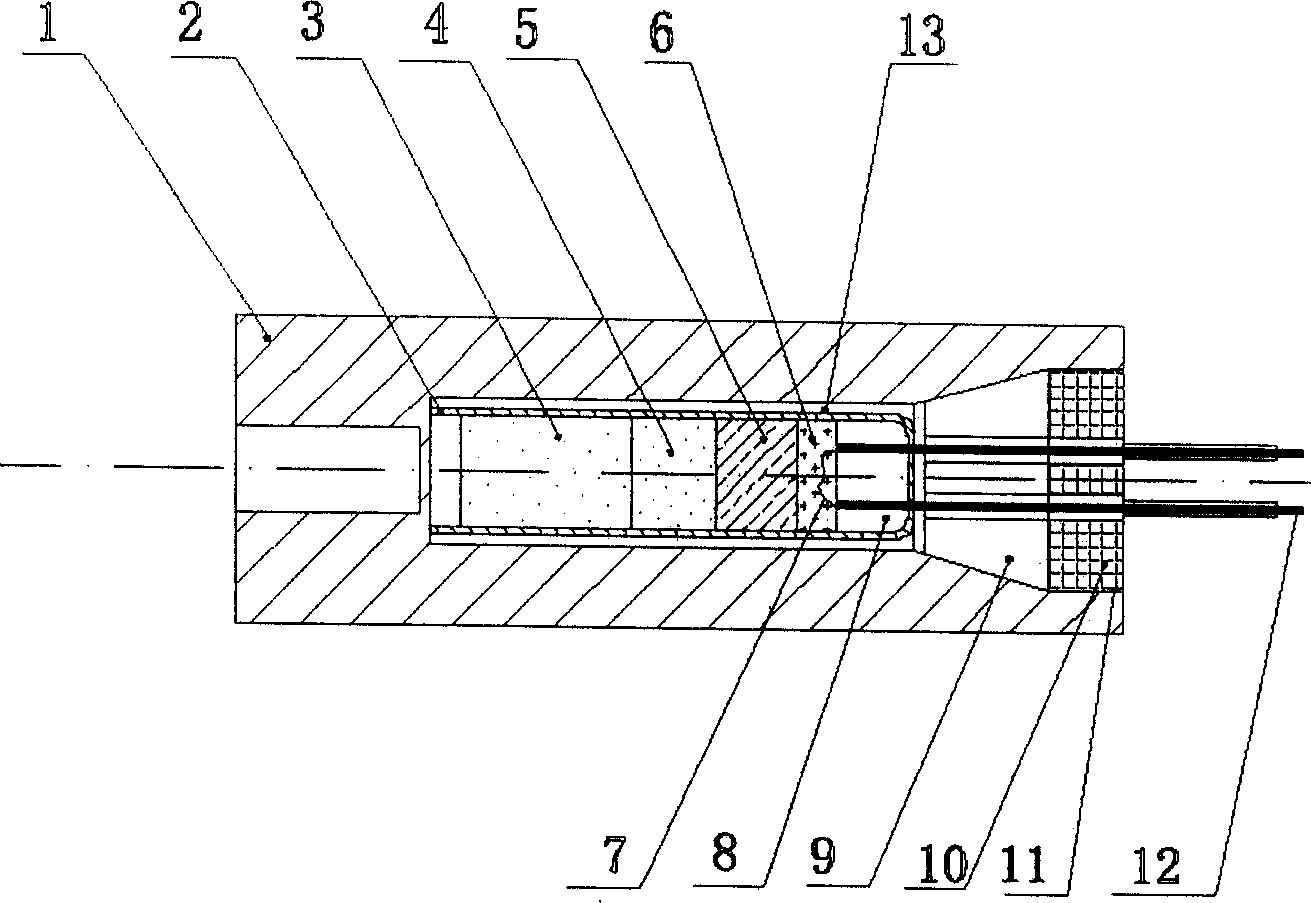

[0015] The charging process is the flip-chip method. First put the glass electrode plug (8) with the nickel-chromium bridge wire (7) welded and the foot wire (12) inside into the common industrial detonator shell (2), and the foot wire (12) is preferably bonded to the glass The Dumet wire; then the detonator shell (2) is packed into the powder pressing mold, and the first layer of charge at one end of the nickel-chromium bridge wire (7) is an ignition powder (6), and the ignition powder is a granular potassium picrate crystal; The second charge next to the ignition powder (6) is the primer (5), the primer is carboxymethyl cellulose lead nitride, its crystal form is a spherical or elliptical polymer crystal, and it has the performance of high temperature resistance above 230°C ; The third layer of charge next to the primer is loose explosive (4), the fourth layer of charge next to the loose explosive is heat-resistant explosive (3), and the loose explosive and heat-resistant ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com