Friction lining plates

一种摩擦衬、摩擦片的技术,应用在摩擦衬片、摩擦离合器、制动盘等方向,能够解决费事等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

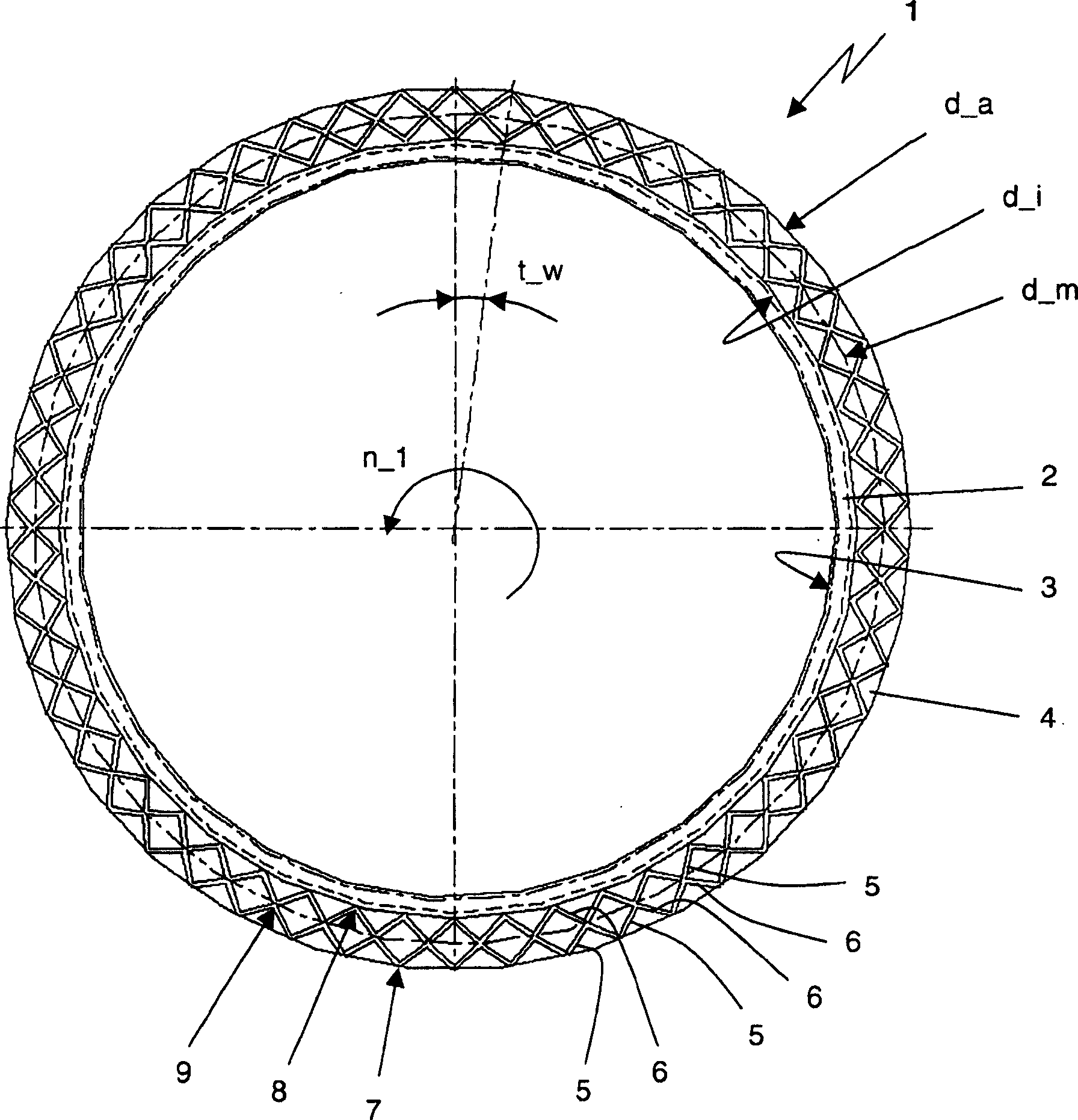

[0026] In the drawing, 1 designates a friction lining, for example in a sandwich construction, with an annular disk-shaped support plate 2 and a likewise annular disk-shaped friction lining, which is in the A flat end face of the carrier plate 2 is fixedly connected to the carrier plate, for example by means of adhesive bonding. The carrier plate 2 is made of steel, for example, and has a clamping contour 3 for a form-locking connection to a friction lining carrier (not shown here), which is located, for example, at the center of the carrier plate 2 . on the inside diameter. Of course, a corresponding clamping contour can also be provided on the outer diameter of the support plate in another configuration of the friction lining-friction lining.

[0027] The flat annular disk-shaped upper side of the friction lining forms the friction surface 4 for the friction engagement of the friction lining 1 and is geometrically defined by an outer diameter d_a and an inner diameter d_i. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com