Electrical connector

A technology of electrical connectors and sensors, applied in the direction of connections, inductors, circuits, etc., can solve problems such as connector arcing, connector pollution, abnormal equipment, etc., achieve effective electromagnetic coupling, reduce complexity, eliminate mechanical and The effect of the need for electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

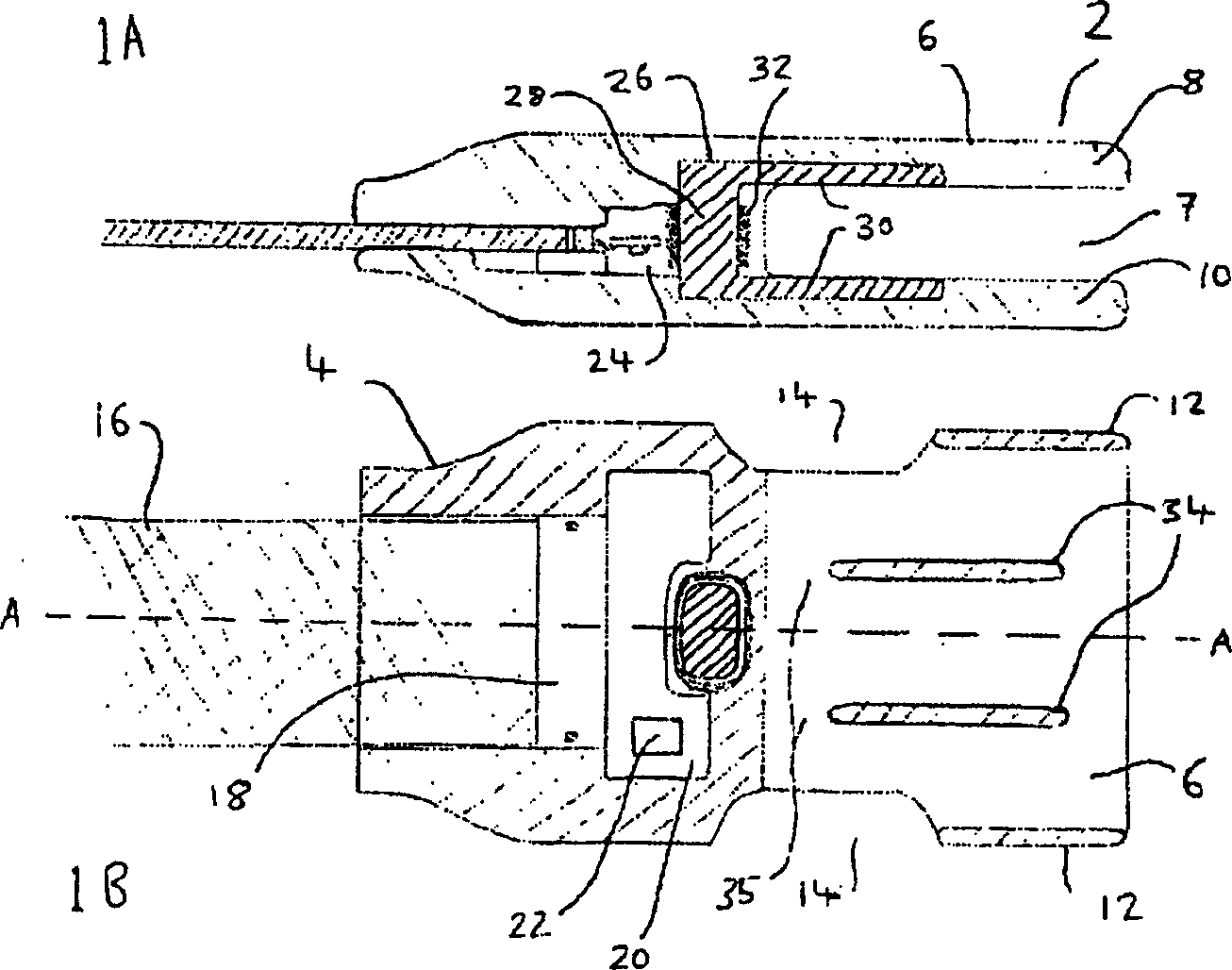

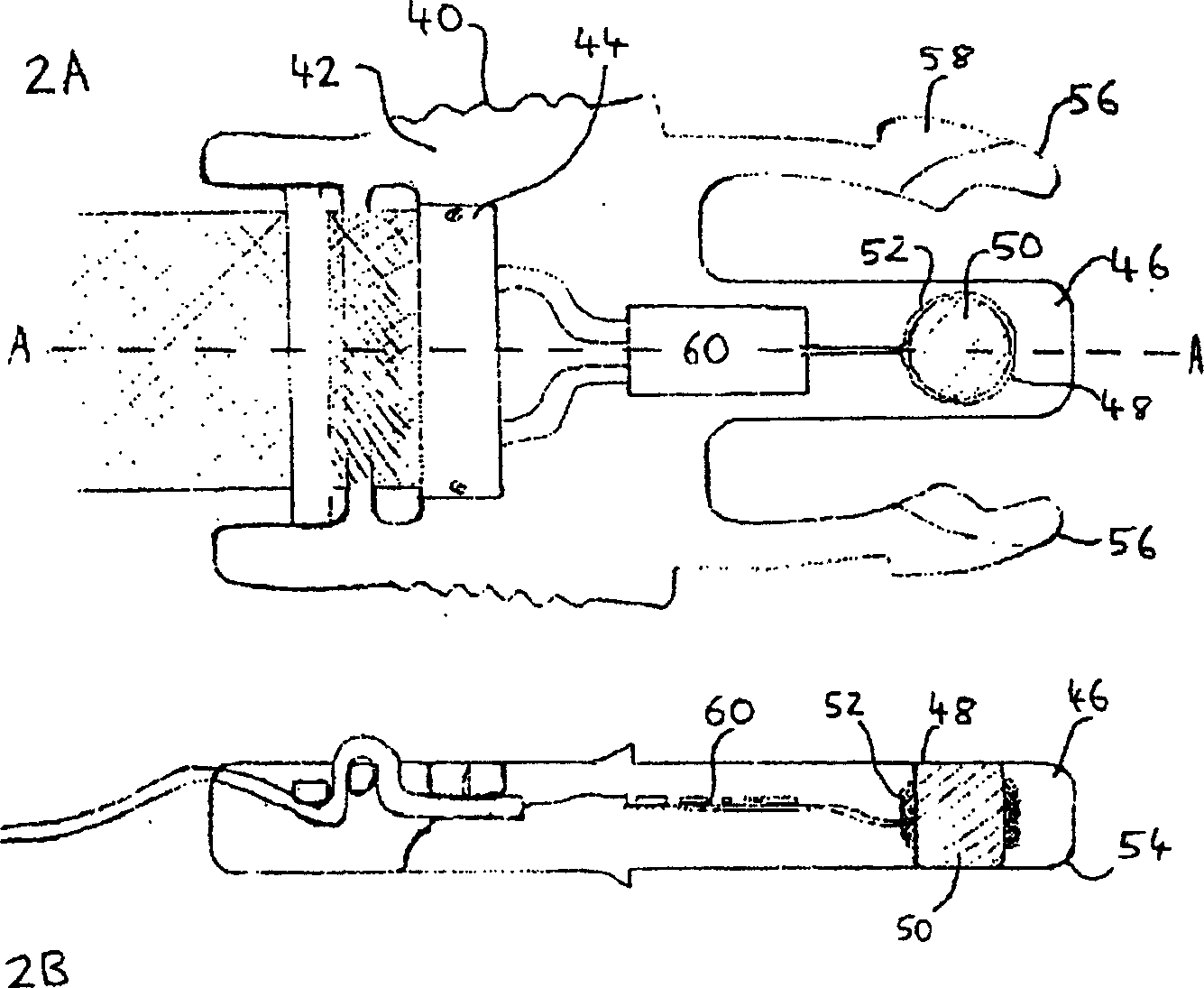

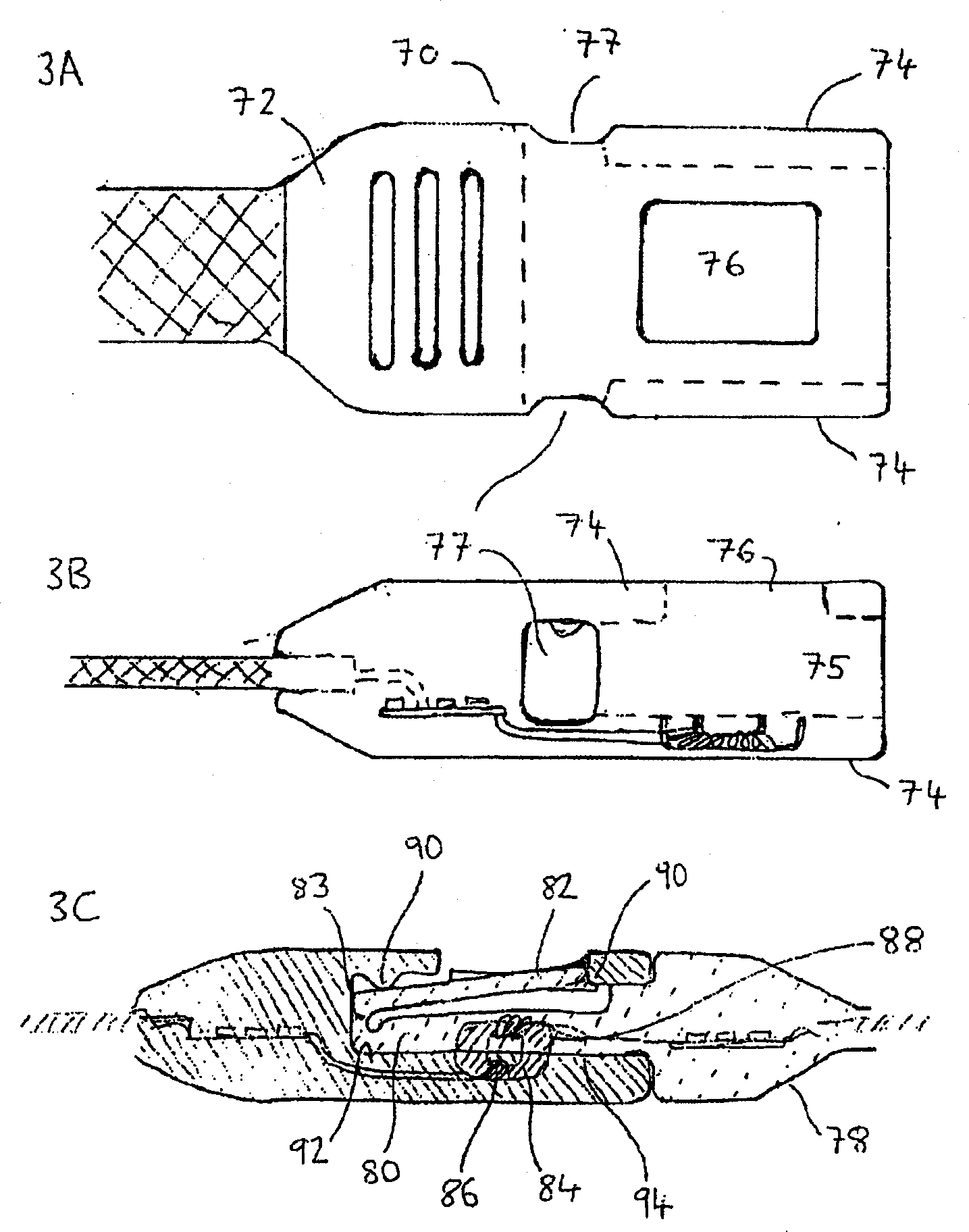

[0093] figure 1 A denotes the socket portion 2 of the non-contact connector of the present invention. The connectors have a structure similar to press-release clips or hooks generally found on rucksacks (see figure 2 Tongue 40 in . The socket part has a base 4 and a wall 6 extending from the bottom to define a socket 7 . The smooth curve of the slot portion makes it more comfortable for the user to use and carry. The socket walls include opposing upper walls 8 and lower walls 10 extending from the base, and two opposing walls 12 extending from the outlet of the socket to approximately the middle along the length of the socket. This arrangement provides a gap 14 between the base 4 and the side wall 12 on each side of the slot. These notches 14 act as pawls, and they cooperate with snap locks 56 at the tongue (see figure 2 ) work together. Such detents may also be provided, for example, by holes or openings in the socket walls, or by, for example, indentations or protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com