Stone-made cinerary casket supersonic mould and sculptering method

An ultrasonic wave and urn technology, which is applied in the field of stone urn carving molds and manufacturing methods, can solve problems such as environmental and human damage that cannot be solved, and achieve the effect of maintaining artistic style, unique structure, and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

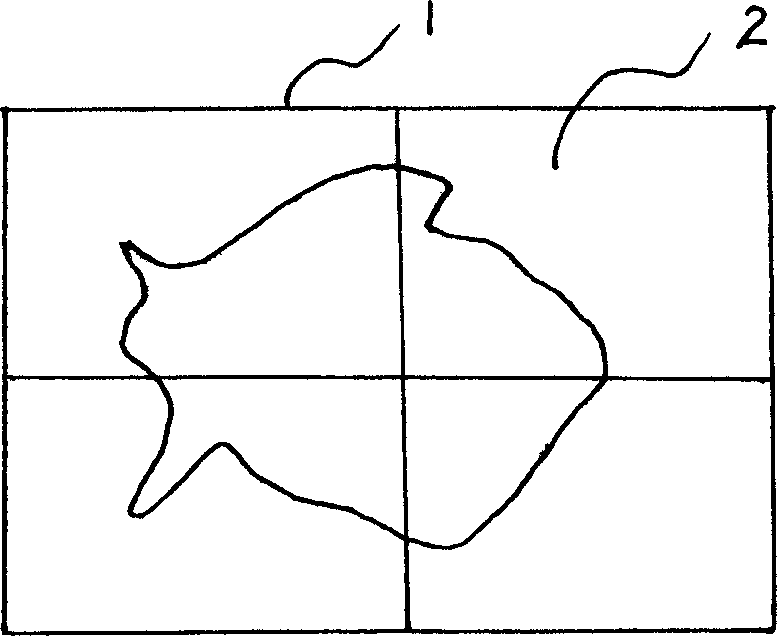

[0010] Embodiment 1: with reference to attached figure 2 . In the ultrasonic mold for a stone urn, the convex and concave mold pattern of the ultrasonic mold 1 is composed of two or more sub-molds 2, and the two or more sub-molds 2 form a round pot-shaped ultrasonic mold or a planar ultrasonic mold. The processing and manufacture of the ultrasonic mold 1 is a prior art, and will not be described here.

Embodiment 2

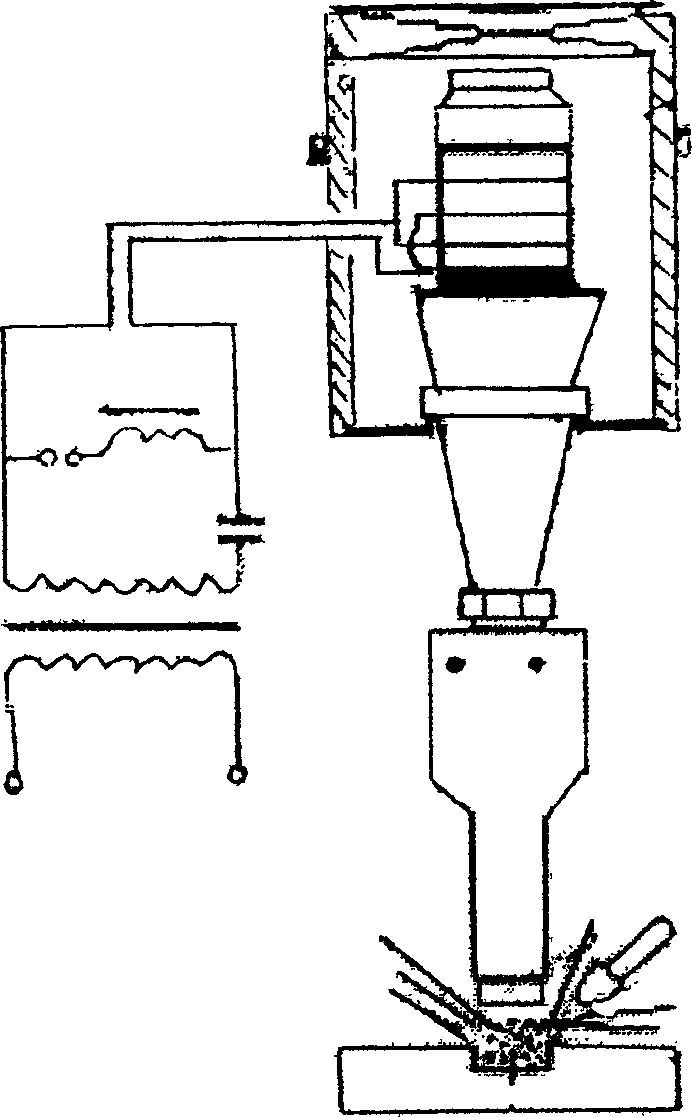

[0011] Embodiment 2 refers to the appended figure 1 with 2 . On the basis of Example 1, the engraving method of the stone urn ultrasonic mold and the use of engraving tools: use engraving tools for ultrasonic engraving, not only the quality of the engraving tools must be good, but also the reasonable connection and installation with the ultrasonic processing machine can make the ultrasonic Engraving went smoothly. Generally speaking, the engraving tool can be fixed on the lower end of the horn of the ultrasonic processing machine by means of welding or screw connection, and it should be considered that the antinode position of the vibration should be basically at the end surface processed by the engraving tool. The weight of the sculpting tool can affect the resonant frequency. Therefore, when the engraving tool is not large, the influence of the engraving tool on ultrasonic vibration can be ignored; when the engraving tool is large and heavy enough, this factor should be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com