Snail-type vertical centripetal straight-tooth shaft drived non-equal-torque cylinder electric dual-power engine

An engine and shaft drive technology, applied in the field of torque cylinder electric dual-power engine, can solve problems such as energy loss, torque imbalance, etc., achieve the effect of balanced driving force, simple realization, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail below in conjunction with specific embodiment:

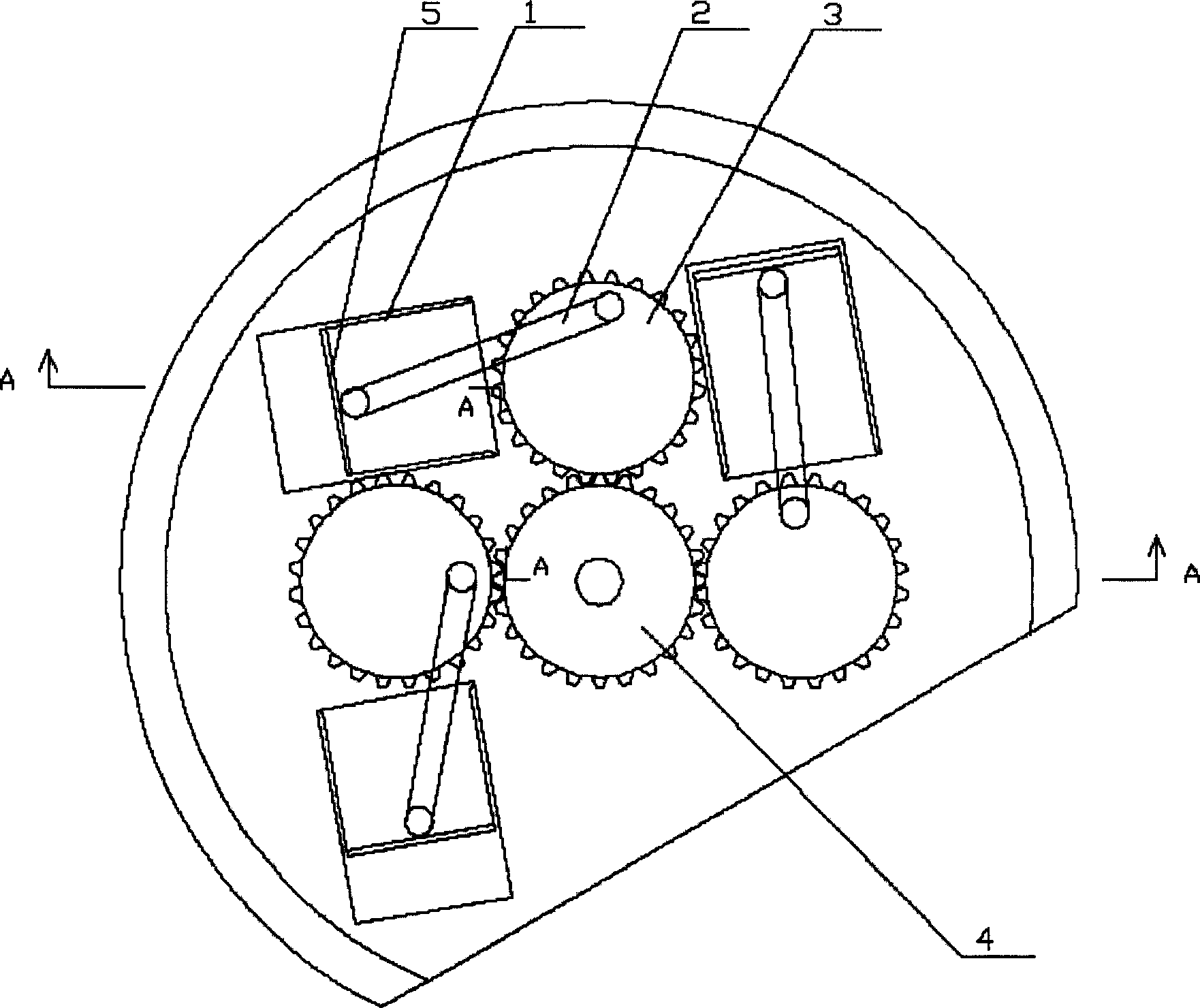

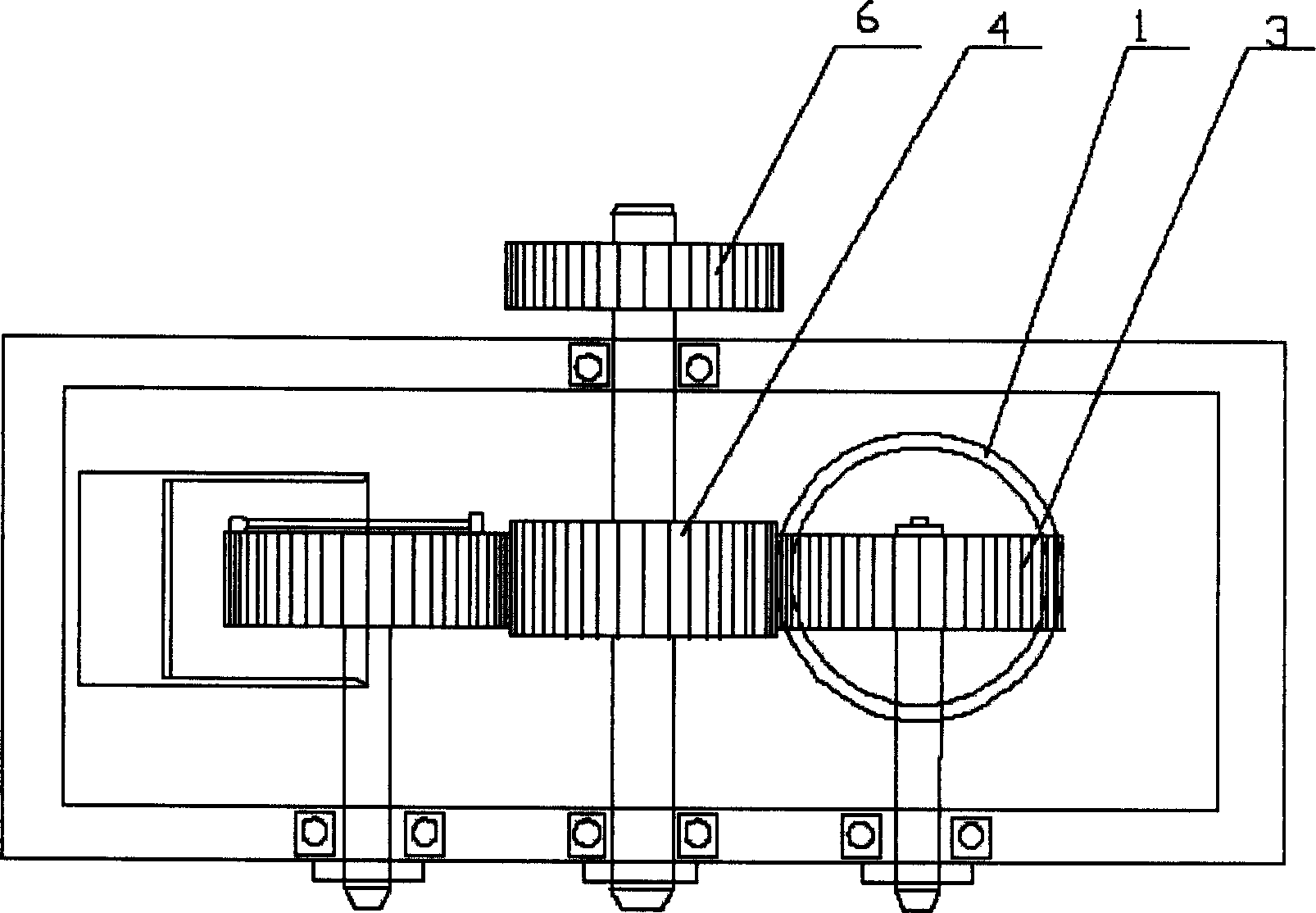

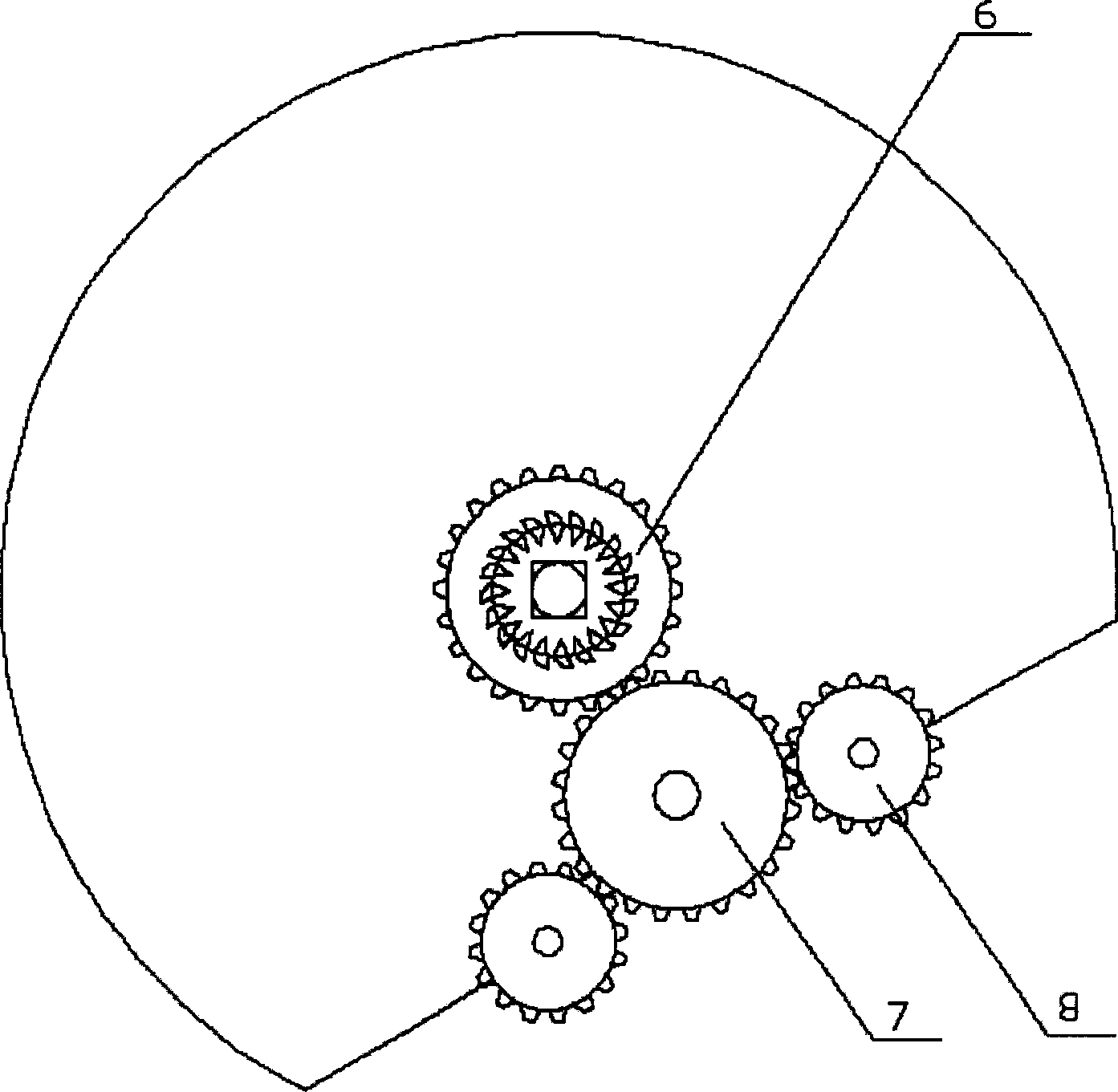

[0039] Such as figure 1 , figure 2 , image 3 Shown, the present invention comprises and comprises center straight drive shaft 4, eccentric shaft movable gear plate 3, cylinder 1, piston 5, transmission push-pull chain bar 2, the output main drive one-way gear 6 outside the machine, and engine is snail-shaped, and its interior There are multiple cylinders 1 arranged in a vertical ring in the engine. There is a piston 5 that can slide horizontally inside the cylinder 1. The piston 5 is linked with the transmission push-pull chain rod 2. The front end of the transmission push-pull chain rod 2 is fastened by screws and connected to the On the eccentric shaft on the eccentric shaft moving gear plate 3, the eccentric shaft moving gear plate 3 converts the reciprocating pull of the transmission push-pull chain rod 2 into circular motion, and the eccentric shaft moving gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com