Diesel particulate filter

A filter, diesel engine technology, applied in the direction of dispersed particle filtration, machine/engine, mechanical equipment, etc., can solve the problems of DPF damage, rising combustion temperature, etc., to avoid the deterioration of working state and fuel consumption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

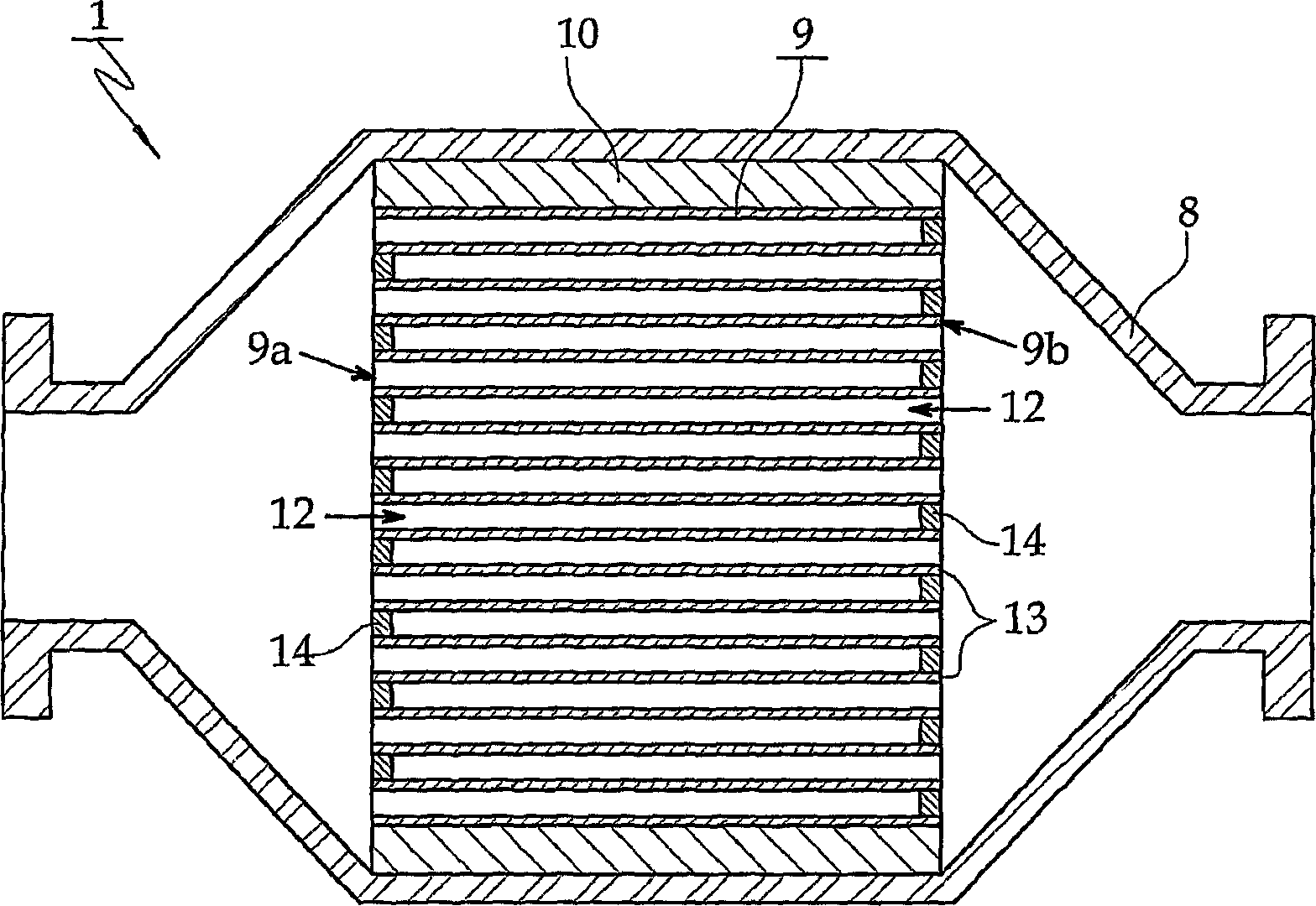

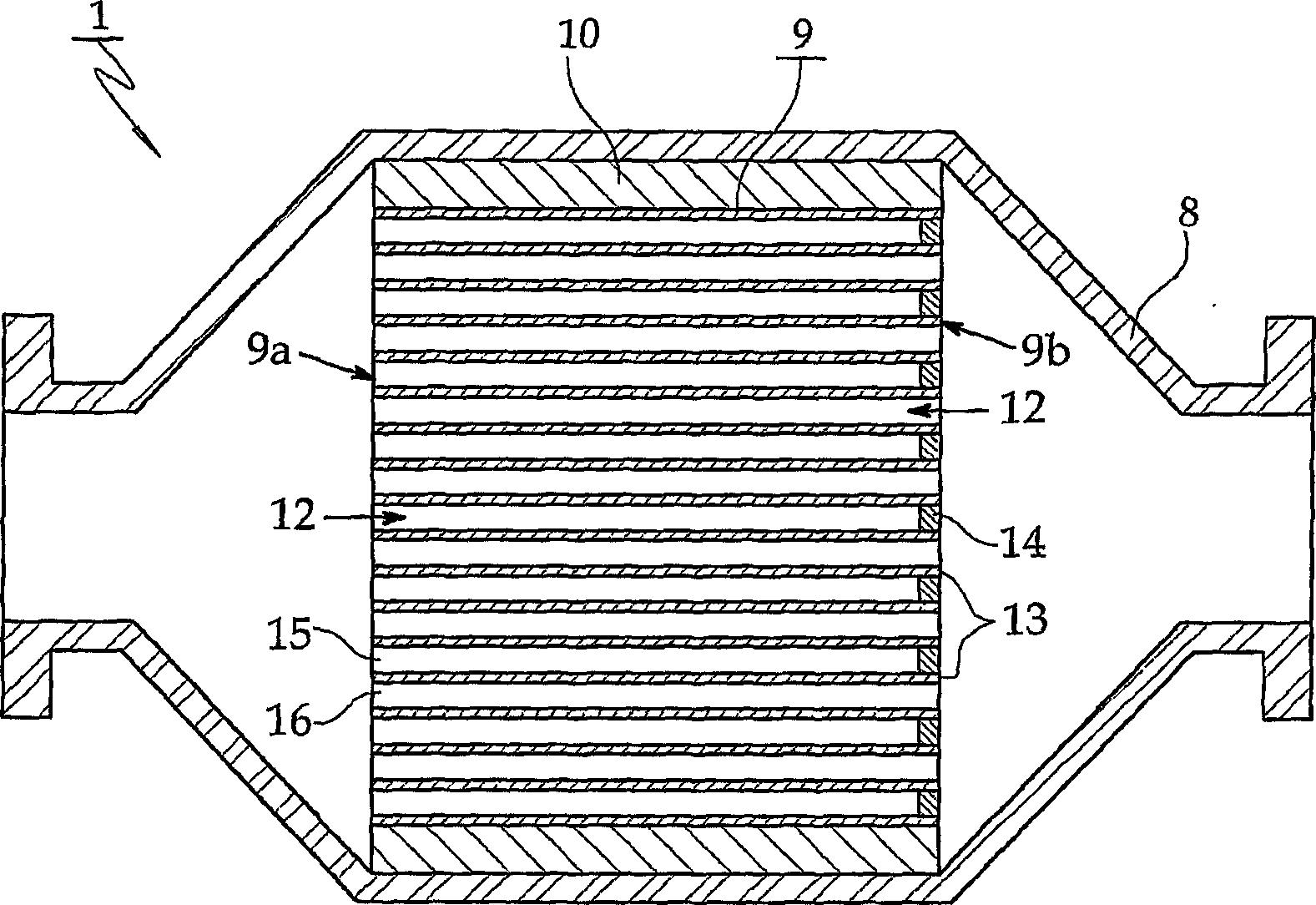

[0030] image 3 is a cross-sectional view of a housing with a filter structure according to the present invention.

[0031]In a cylindrical filter structure, one end of the cylindrical filter structure from which the discharge enters is completely open, and the other end of the cylindrical filter structure from which the discharge exits is partially sealed. The plurality of penetrating cells 12 are composed of sealed cells 15 and open cells 16 . All permeable cells are open at their entry ends. Half of the permeable cells are sealed at their outflow ends by sealant 14 and the remaining half of the permeable cells are open at their outflow ends. The open cells 16 and the sealed cells 15 are provided in substantially equal numbers, and the open cells may be arranged adjacent to the sealed cells so that they form a checkerboard pattern in the cross-section of the filter structure. Alternatively, the open cells may be arranged in a circle around the center of the filter structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com