Method of manufacturing an axially collapsible drive shaft assembly

A compressing flower, axial technology, applied in the direction of shafts, couplings, shafts and bearings, etc., can solve difficult, expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

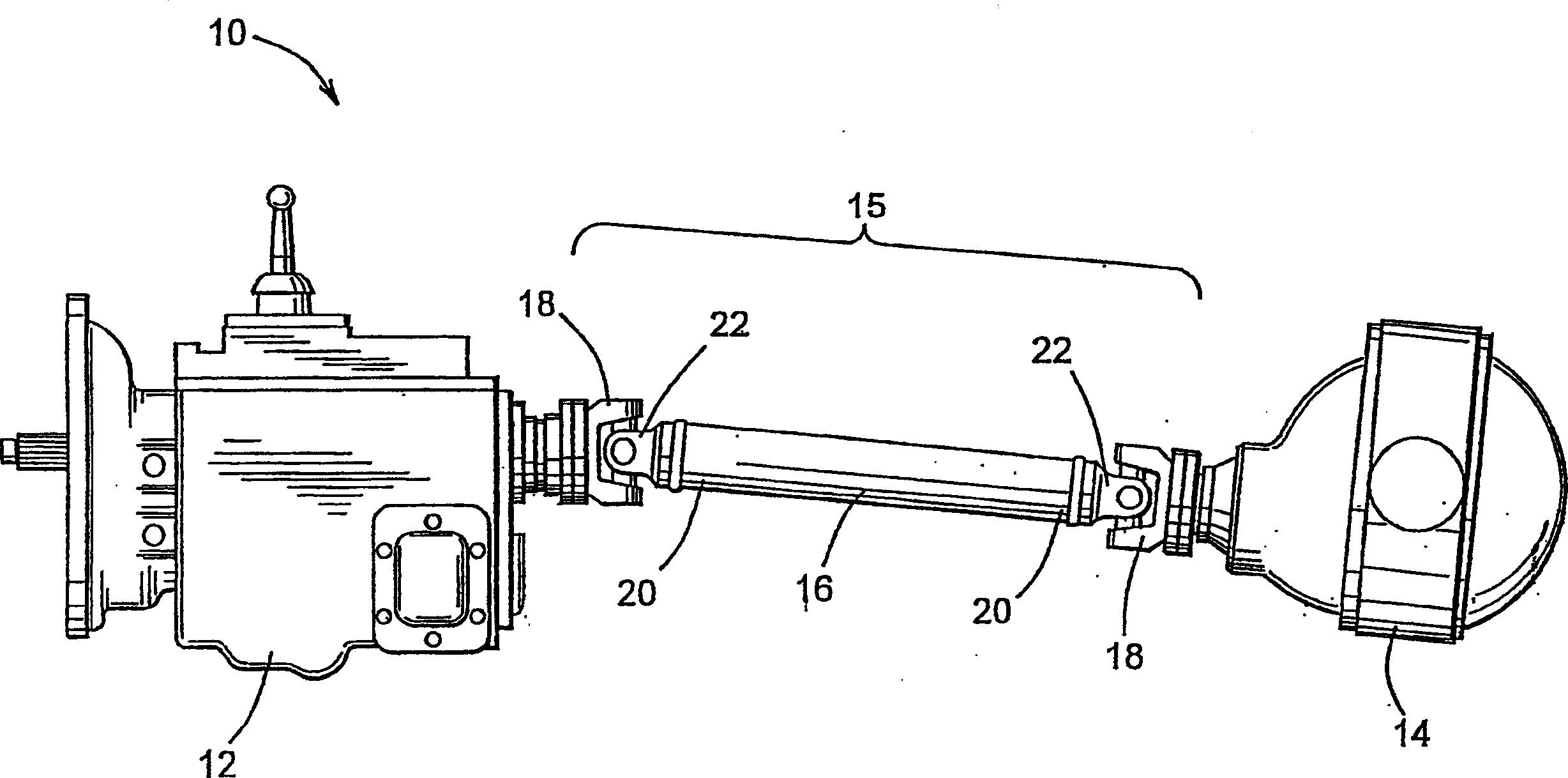

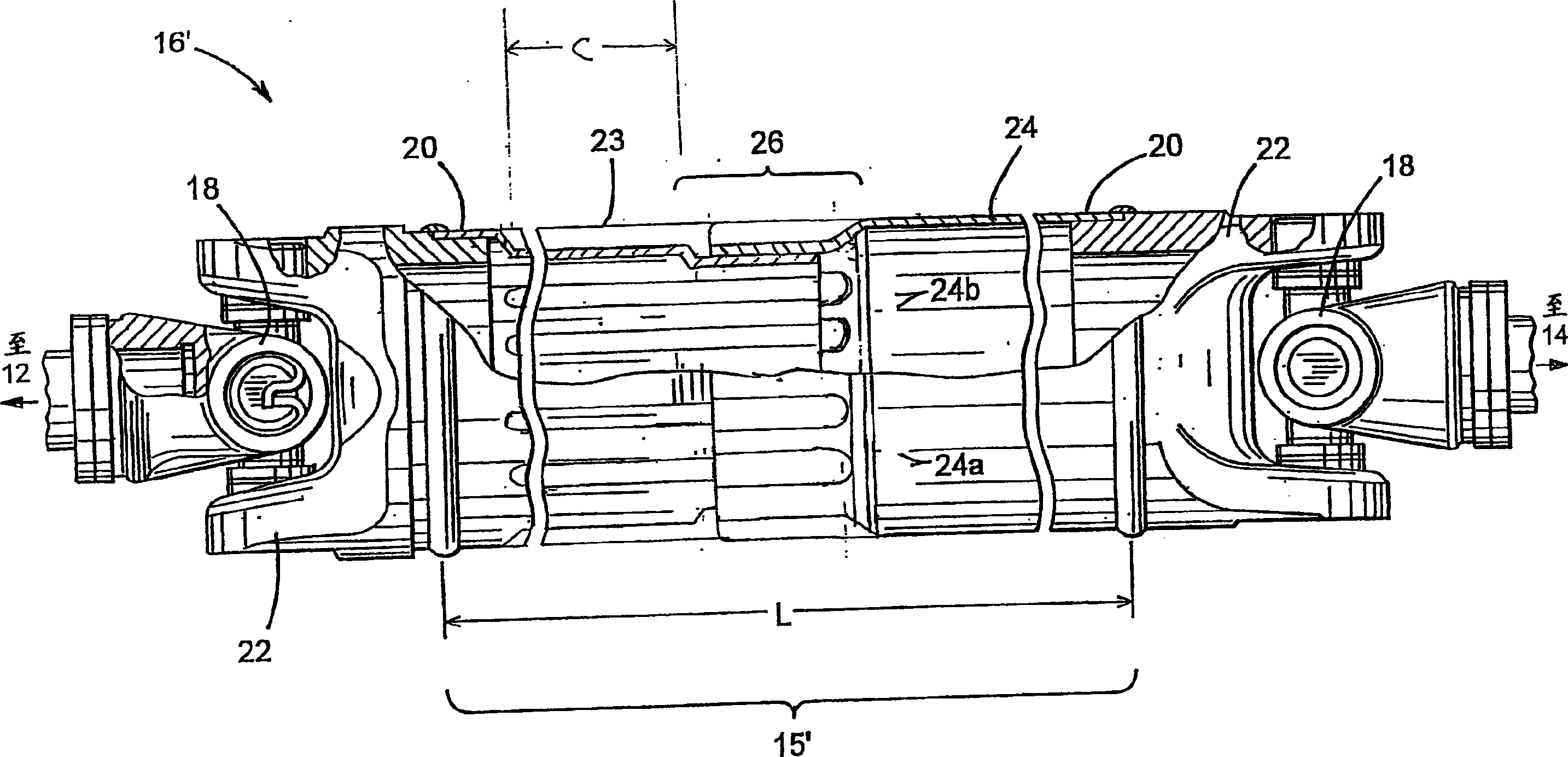

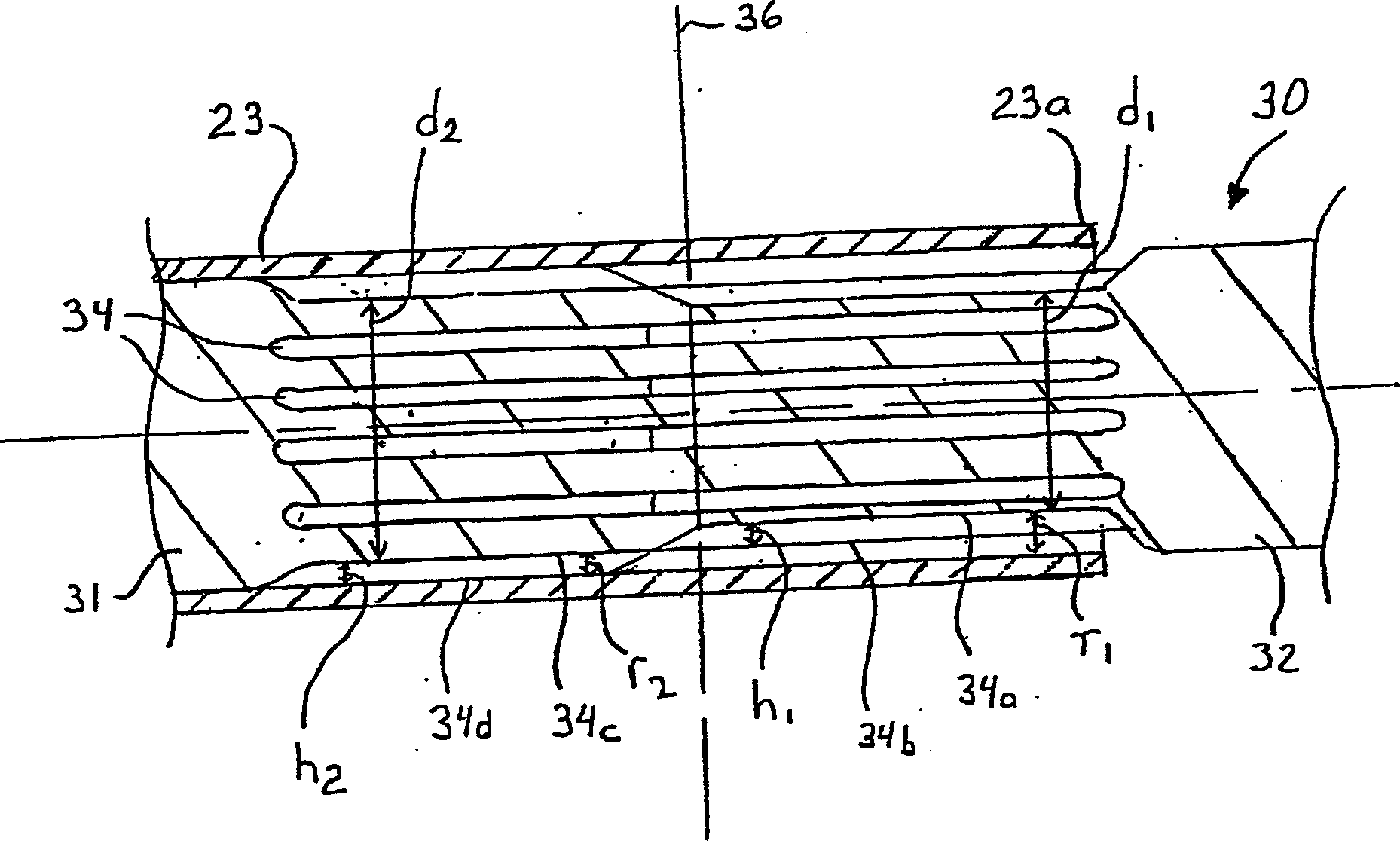

[0022] Referring now to the drawings, there is shown in FIG. 1 a conventional vehicle driveline of the prior art, indicated generally at 10 . A prior art driveline 10 includes a transmission 12 coupled to an axle assembly 14 via a driveshaft assembly 15 . The propshaft assembly 15 includes an elongated cylindrical propshaft tube 16 . As is typical in conventional vehicle drivelines 10 , the output shaft (not shown) of the transmission 12 and the input shaft (not shown) of the axle assembly 14 are not coaxially aligned. Accordingly, universal joints 18 are employed at each end 20 of propshaft tube 16 to rotatably connect propshaft tube 16 at an angle to the output shaft of transmission 12 and the input shaft of axle assembly 14 .

[0023] The connection between the end 20 of the propshaft tube 16 and the universal joint 18 is typically accomplished by a pair of end fittings 22, such as pipe yokes or slide yokes. The end 20 of the drive shaft tube 16 is open and adapted to rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com