Modularly built driver cab model range

A cab, modular technology, applied in the field of cab structure series, to achieve the effect of improved flexibility and flexible manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

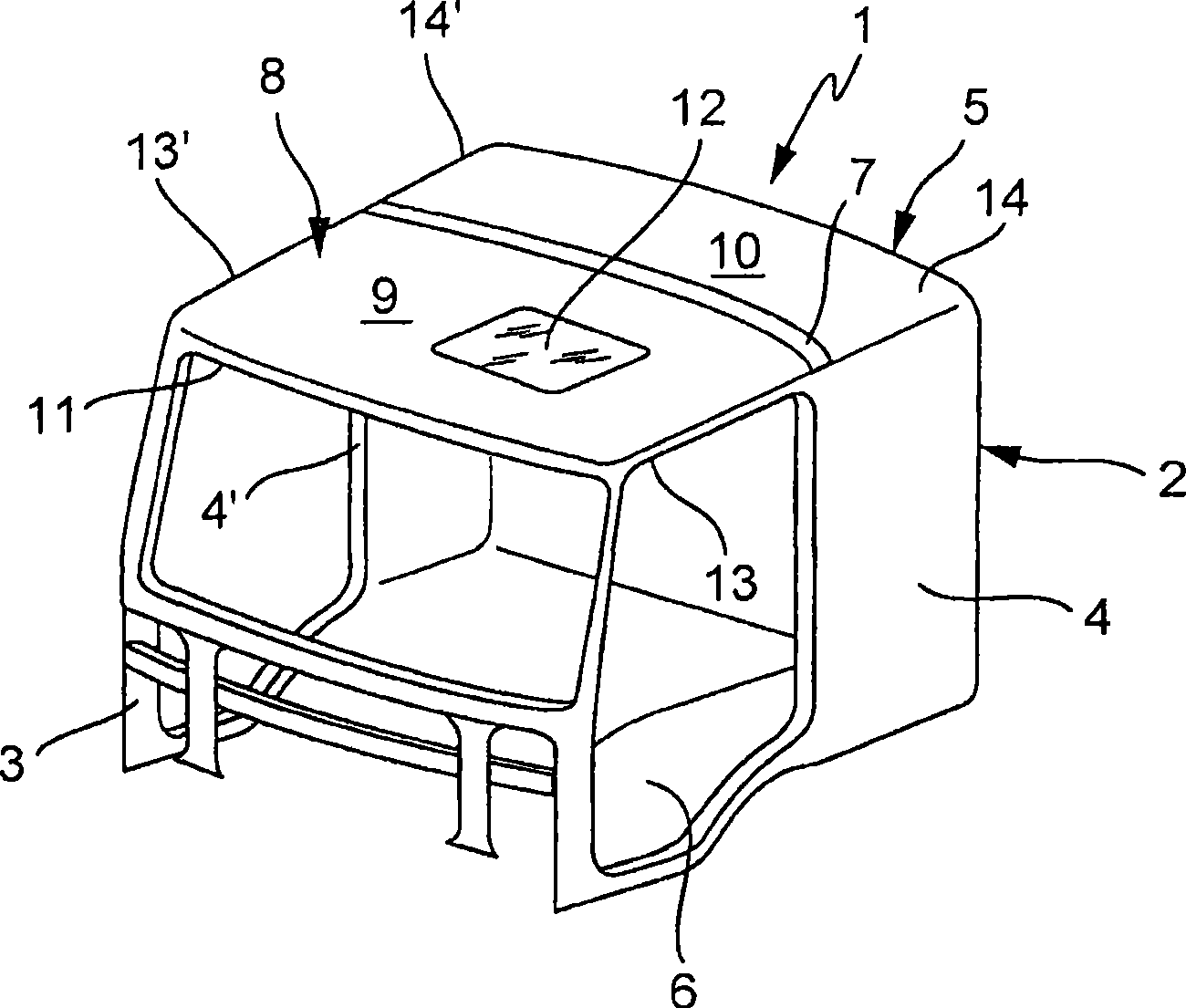

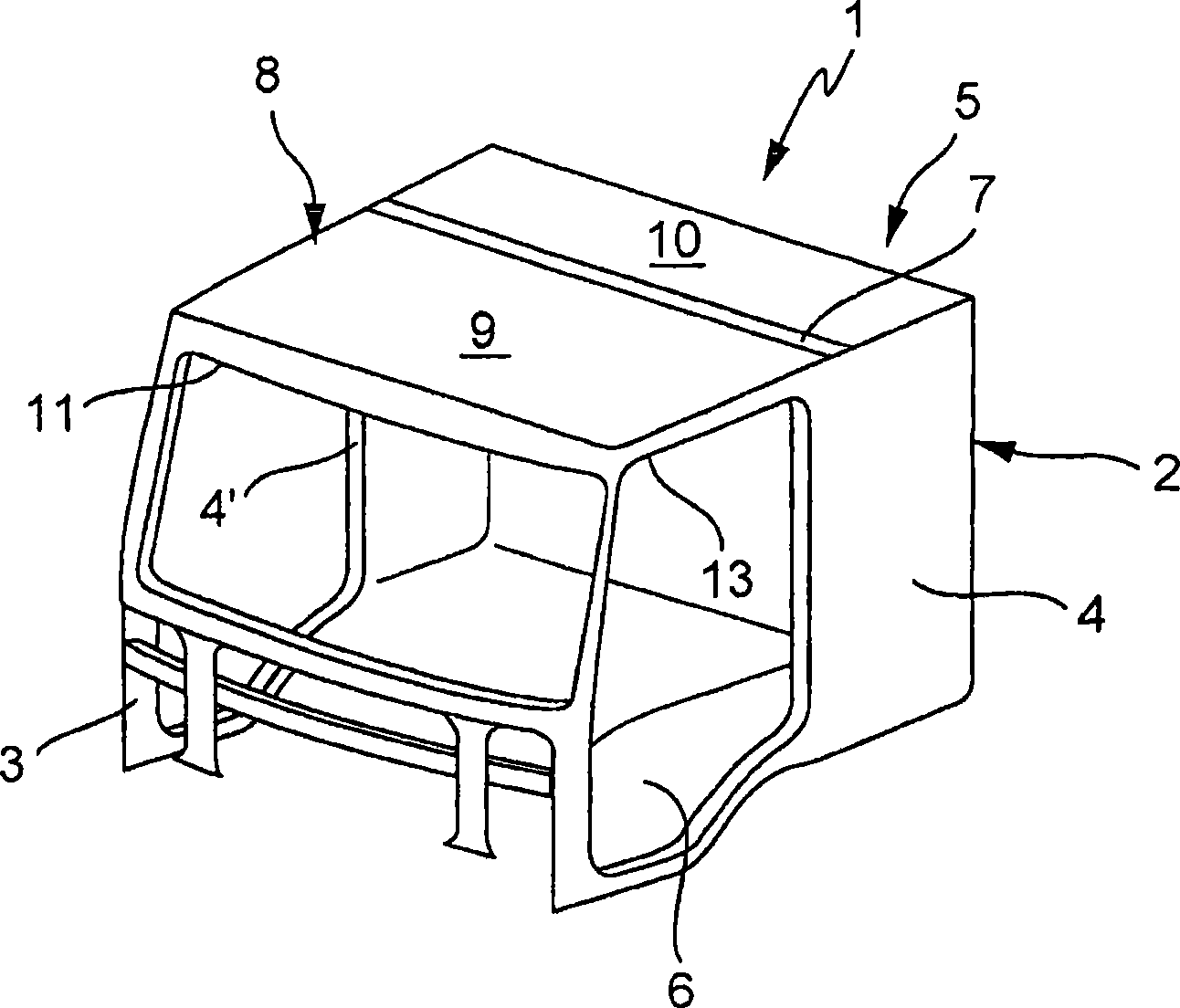

[0025] according to figure 1 , a driver's cab 1 of a modular construction according to the invention of a series of driver's cab structures for commercial vehicles has a substantially uniform base module 2, which has a front wall 3, two side walls 4, 4 ' and a rear wall 5 and a cab bottom 6. The base module 2 of the driver's cab 1 can be fitted to different vehicle chassis, not shown, so that completely different commercial vehicles can be realized. The two side walls 4 , 4 ′ each have a door opening, on which a vehicle door (not shown) can each be arranged. Furthermore, the two side walls 4 , 4 ′ are connected to one another at a front end viewed in the direction of travel by the front wall 3 and at a rear end viewed in the direction of travel by a rear wall 5 in the transverse direction of the commercial vehicle.

[0026] On the roof side, the base module 2 has a transverse bracket 7 which connects the two side walls 4 , 4 ′ and is arranged on the side walls in the region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com