Multi-mode Distributed Control Electrolyzer Control System Based on PLC

A distributed control and control system technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of complex control, operation, management, restricting performance and application, and difficult quality assurance, so as to improve control reliability, Powerful data storage function, reducing the effect of cable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

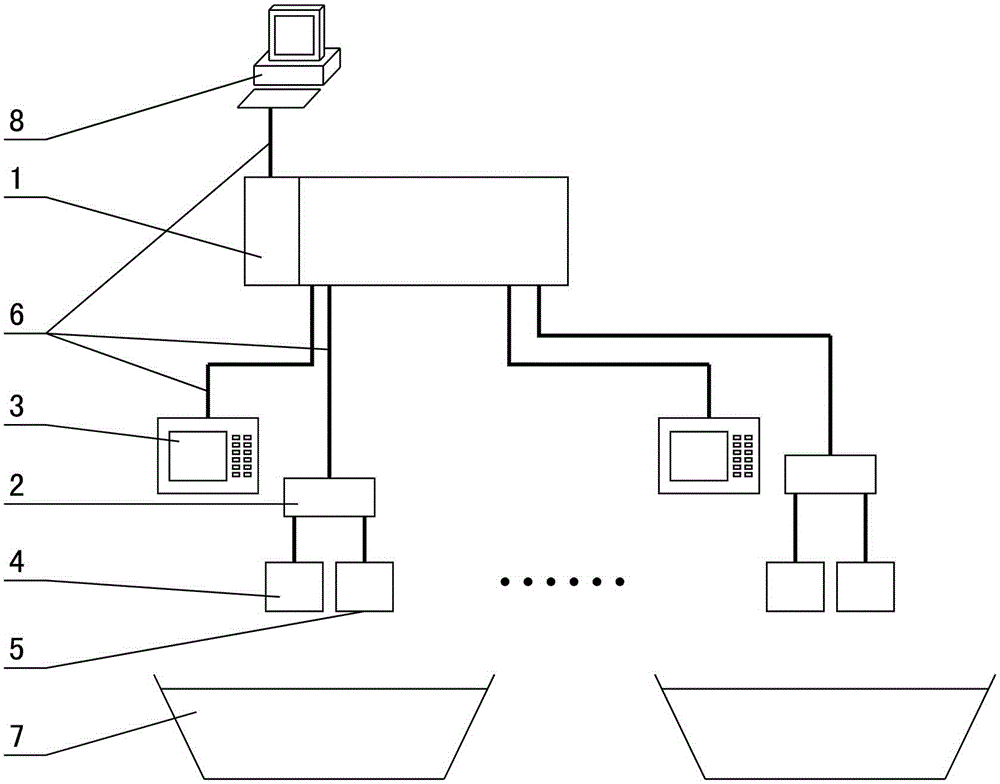

[0015] As shown in the figure, the present invention is based on the multi-mode distributed control electrolytic cell control system composed of PLC, which is composed of the following structure: PLC1, which is used to receive the signal collected by the remote I / O acquisition module 2 and pass it to the anode lifting control module after processing 4 and the shelling and cutting control module 5; the I / O acquisition module 2 is used to collect the signal of the electrolytic cell 7 and transmit it to PLC1; the anode lifting control module 4 is used to receive the control signal of PLC1; the shelling and cutting The control module 5 is used to receive the control signal of PLC1; the electrolytic cell information display module 3 is used to receive the display signal of PLC1; there are 3-5 electrolytic cells 7.

[0016] PLC1 is connected to remote I / O acquisition module 2 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com