Fuel injection valve

A technology of fuel injection and fuel oil, which is applied in the direction of fuel injection devices, fuel injection valves driven by fluid pressure, engine components, etc. It can solve the problems of temporary changes in the lifting amount of the armature stopper and easy lifting, etc., so as to improve the service life , reduced friction, long-term reliable and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in more detail below with reference to these figures.

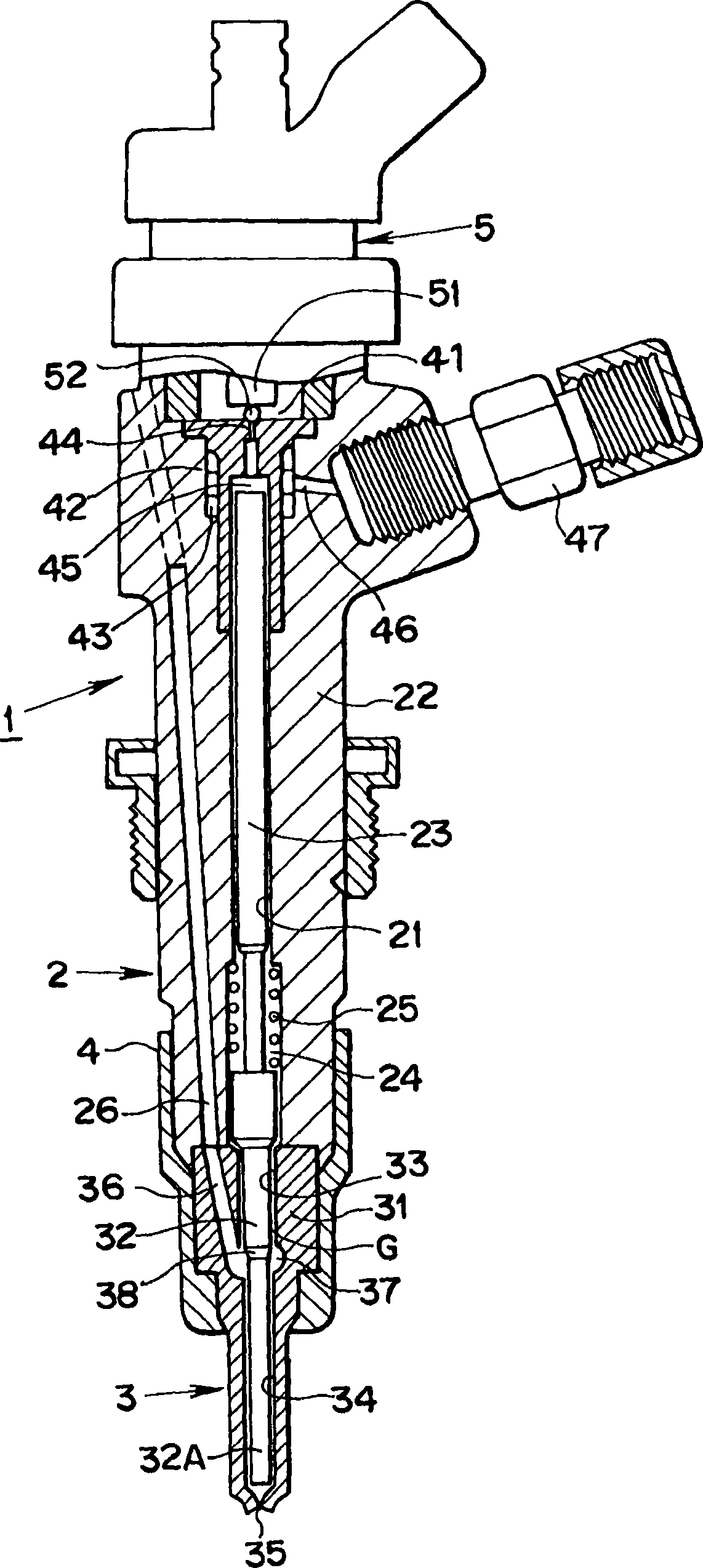

[0016] figure 1 is a sectional view showing an example of an embodiment of the fuel injection valve according to the present invention. Denoted by reference numeral 1 is a fuel injection valve used in a common rail system for injecting / supplying fuel to a diesel internal combustion engine. This fuel injection valve 1 is mounted on a cylinder of an unshown diesel internal combustion engine, and is used to directly inject / supply only the required amount of high-pressure fuel supplied from the unshown common rail into the inside of the cylinder and at a desired timing . The fuel injection valve 1 includes a fuel injection nozzle bracket 2, the fuel injection nozzle 3 is fixed on the front end of the fuel injection nozzle bracket 2 by a fastening nut 4, and the solenoid valve 5 is arranged on the rear end of the fuel injection nozzle bracket 2.

[0017] The nozzle holder 2 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com