Printing device and use method thereof

A printing device and printing board technology, applied in the direction of conductive pattern formation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

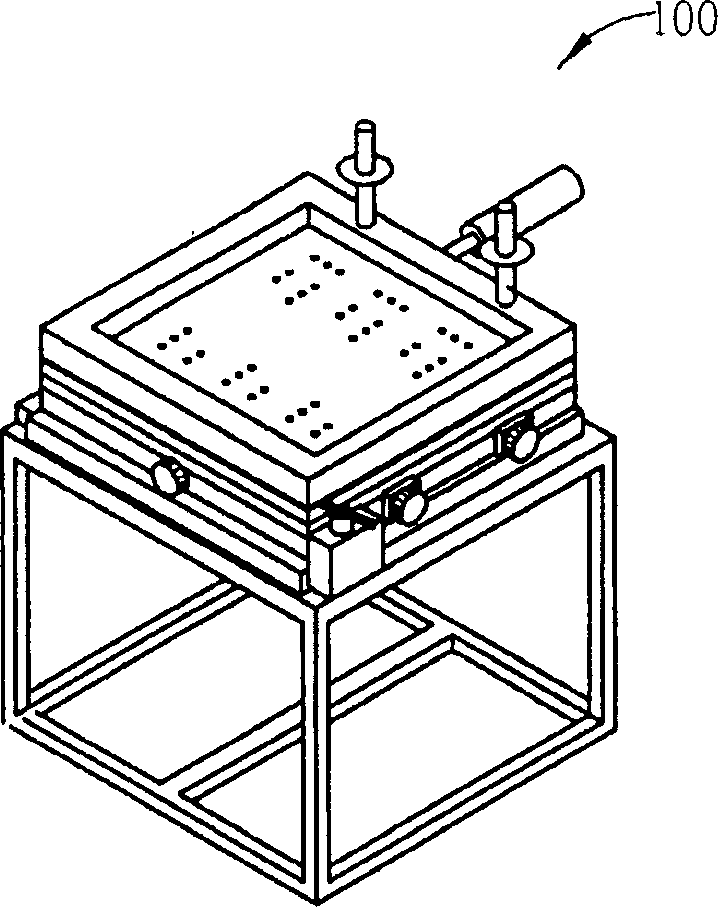

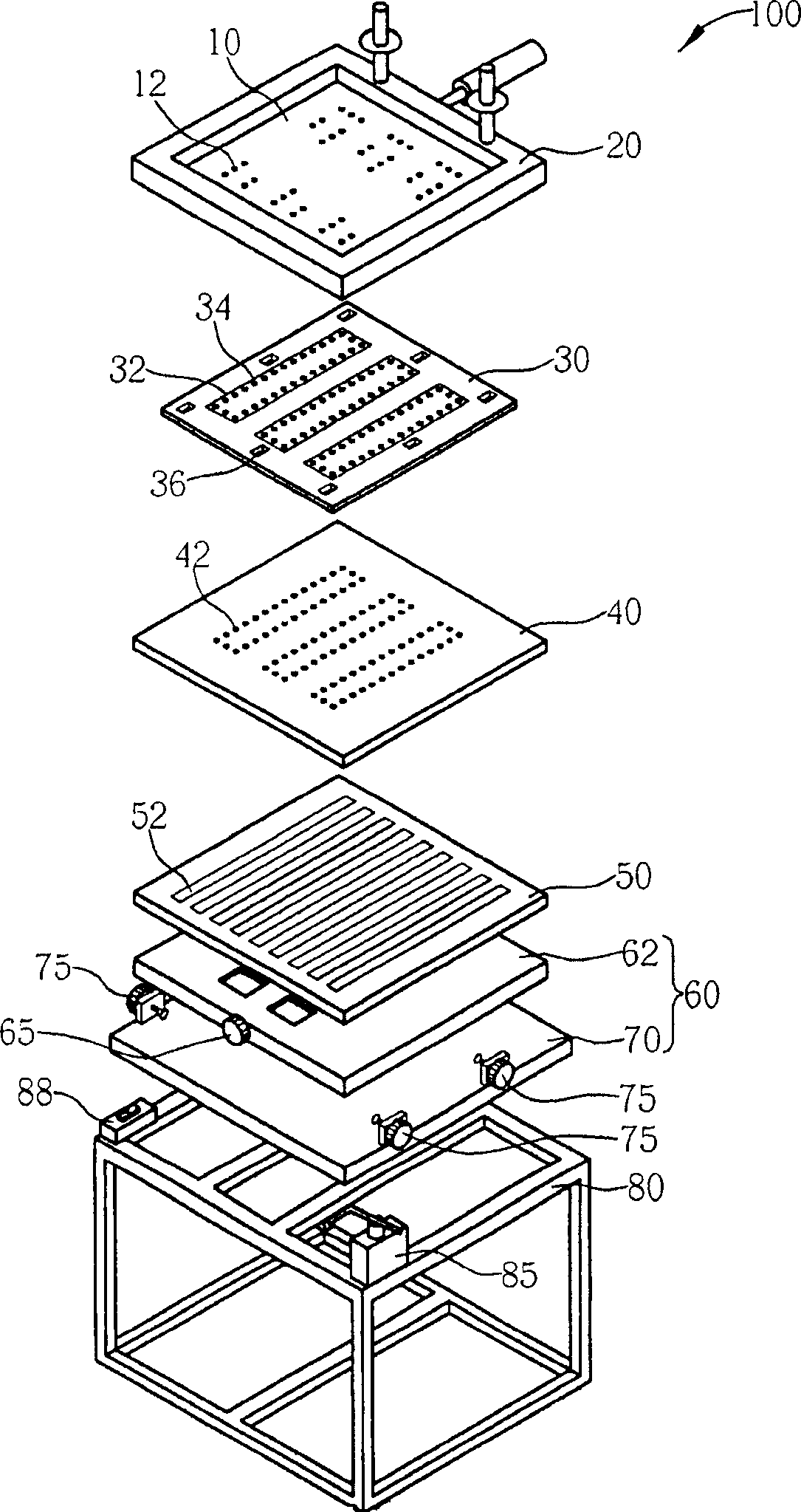

[0028] Please refer to figure 1 and figure 2 , figure 1 It is a schematic structural diagram of a printing device 100 in a preferred embodiment of the present invention, figure 2 It is an exploded schematic view of each component of the structure of the printing device 100 according to the preferred embodiment of the present invention. Such as figure 2 As shown, the structure of the printing device 100 of the present invention includes a printing plate 10 , a printing plate supporting and fixing module 20 , a loading plate 30 , an upper template 40 , a lower template 50 , a fine-tuning module 60 and a support frame 80 .

[0029] The surface of the printing plate 10 includes at least one printing opening 12 . The printing openings 12 can be set correspondingly according to the positions of the pads on the surface of the circuit board (not shown) where the solder paste is to be printed, so that during the printing process, the solder paste can be printed onto the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com