Liquid crystal display unit and driving method therefor and drive device for liquid crystal display panel

A technology of a liquid crystal display device and a driving method, which is applied to static indicators, instruments, etc., can solve the problems of reducing the polarity inversion frequency and prolonging the flickering period, and achieves the effects of reducing power consumption and preventing flickering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Preferred embodiments of the present invention (hereinafter referred to as embodiments) will be described below with reference to the drawings.

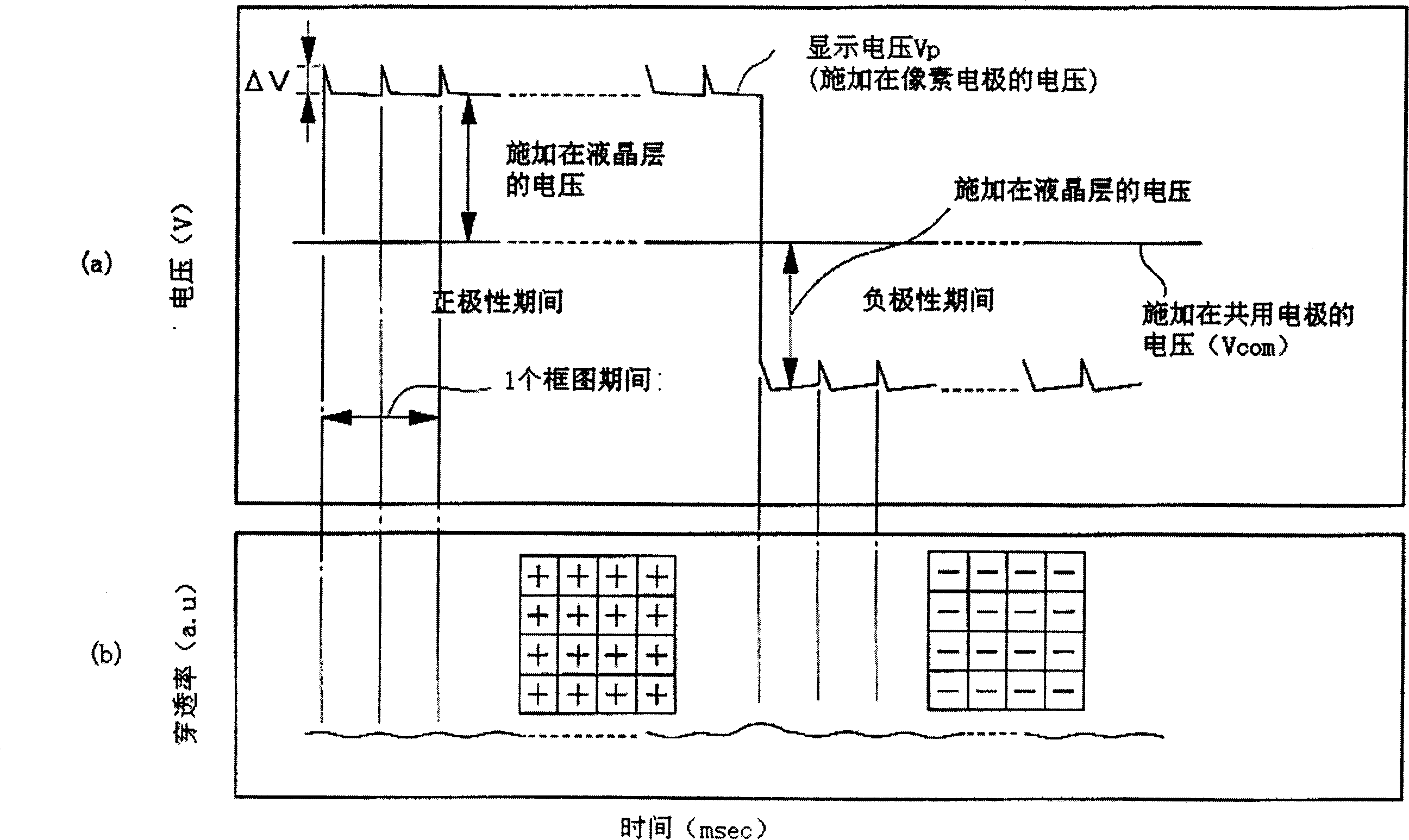

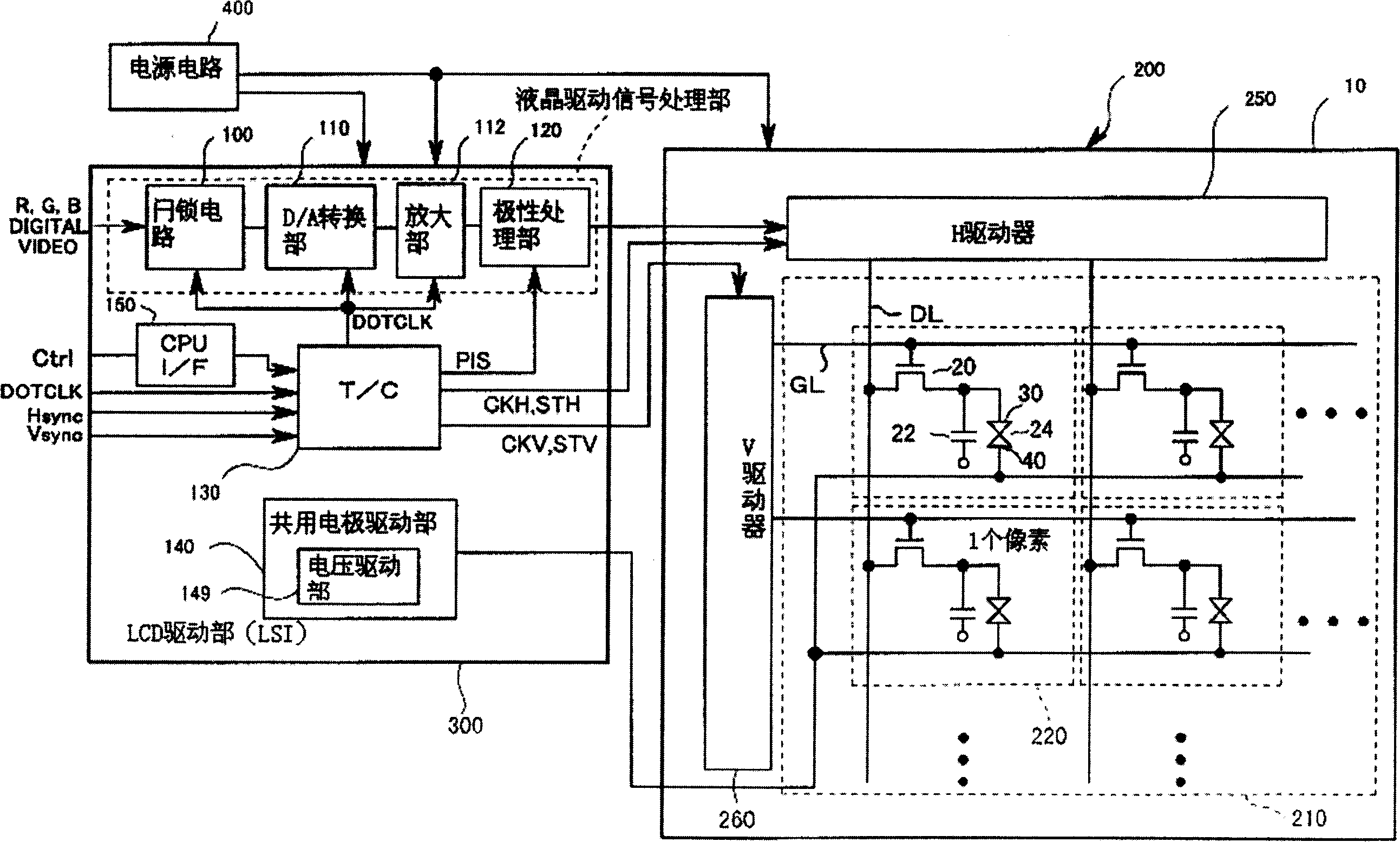

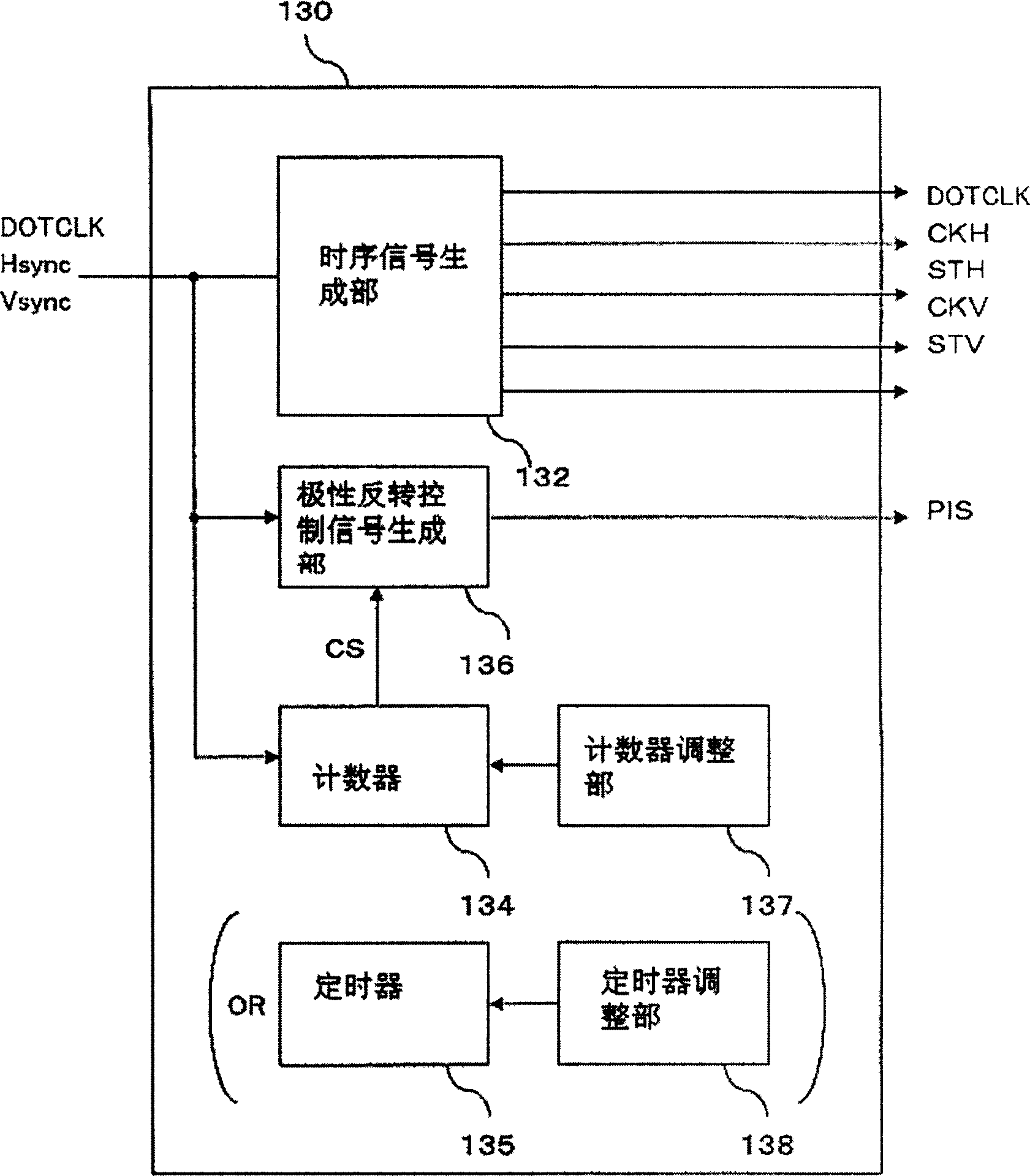

[0049] In the LCD according to the present embodiment, the polarity inversion period with respect to the reference value of the liquid crystal drive voltage is set to a period equal to or longer than two block periods. Making all the pixels constituting one screen have the same polarity means inverting the polarity for each screen, and the pixel polarity in one screen as described above is not implemented for each line or for each pixel. There are different line inversions or dot inversions etc. In addition, such polarity inversion driving is not limited to active-matrix LCDs equipped with switches such as TFTs in each pixel, but can also be applied to simple matrix-type LCDs that do not have switches. In the following, the display quality is better. , especially an active matrix LCD with better animation display quality than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com