Sheet feeding device and image forming apparatus

A paper conveying and paper technology, applied in the field of image forming devices, can solve the problem that the paper loading capacity of the main bottom plate and the sub bottom plate cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

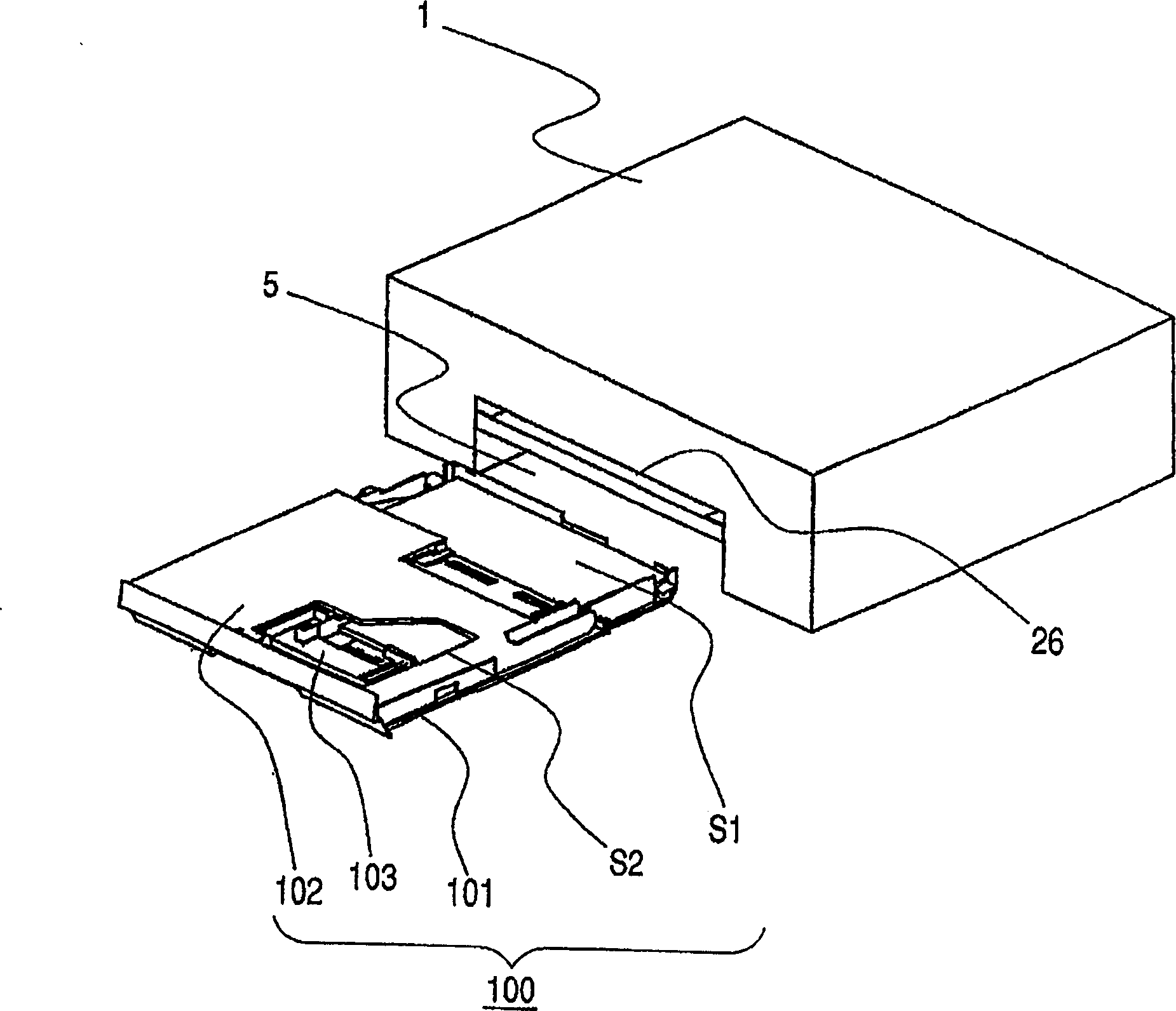

[0033] Such as figure 1 As shown, the paper feeding cassette (paper storage unit) 100 constituting the paper conveying device can be attached or detached from the cassette insertion opening 5 opened on the front surface of the printer main body 1 with the paper S stored therein. The printed paper S is discharged from the paper discharge port 26 .

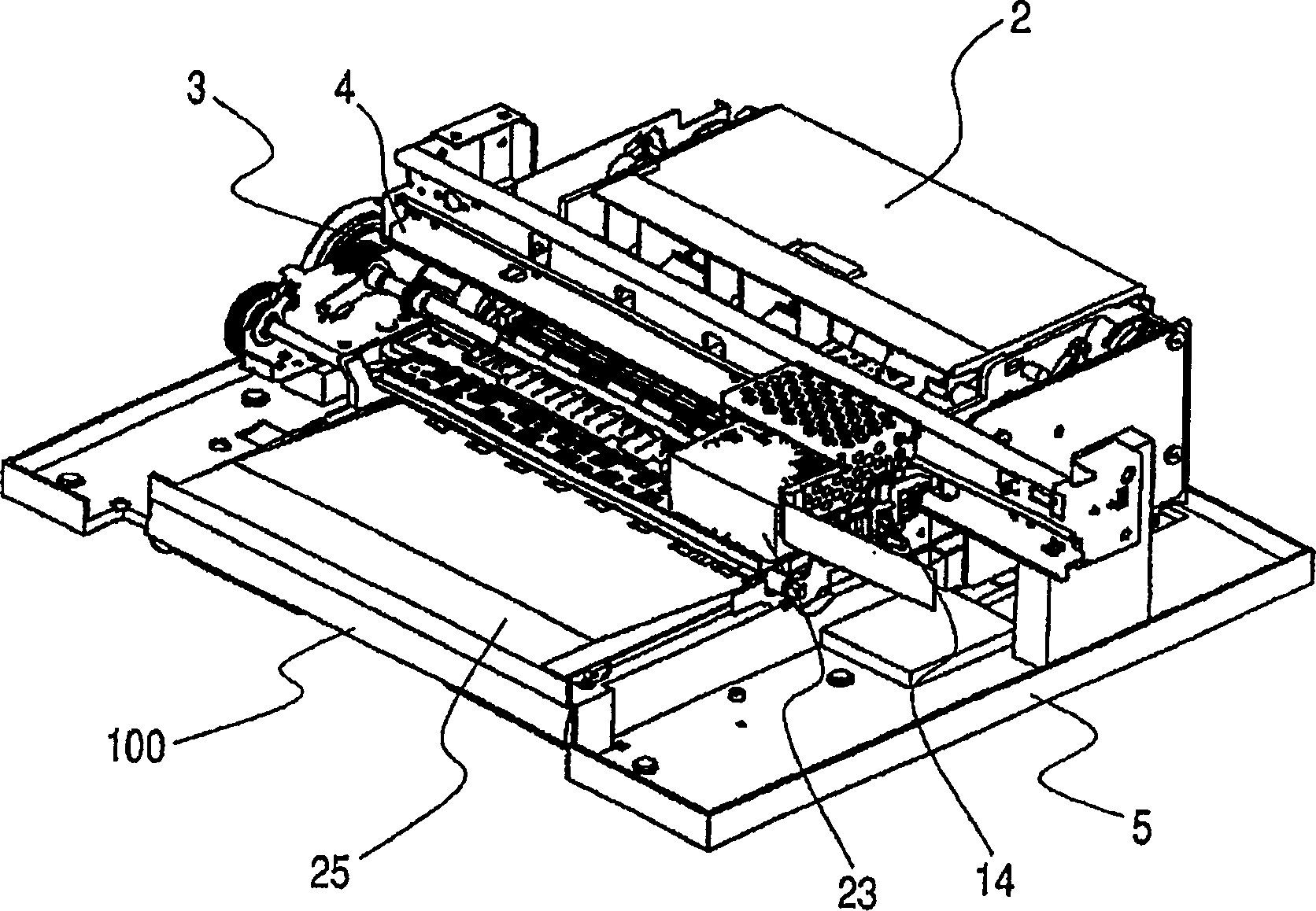

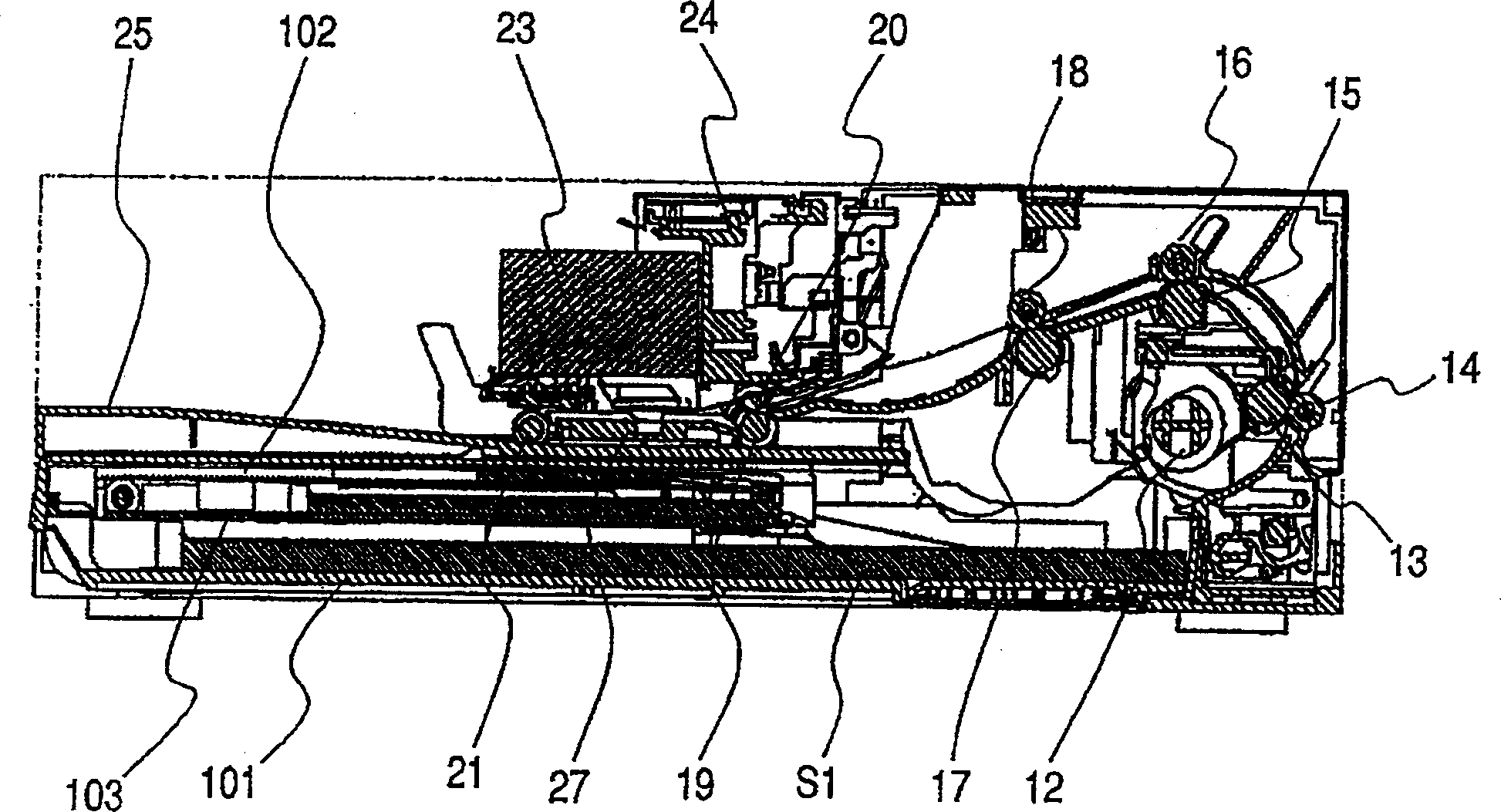

[0034] of the internal structure of the printer body 1 figure 2 Among them, there is a paper feeding unit 2 constituting a paper feeding device together with a detachable paper feeding cassette 100 below the mechanical part, and the paper S fed from the paper feeding cassette 100 is sent to the LF unit 3 . The CR unit 4 has a carriage 14 on which a recording head 23 for printing is mounted, and is a mechanism for reciprocating the carriage 14 in the sub-scanning direction of the sheet S. As shown in FIG. The paper feeding unit 2 and the CR unit 4 have their own independent drive motors, and work together to perform printing opera...

no. 2 Embodiment approach

[0055] Figure 14 A second embodiment that can also be called an application example of the above-mentioned first embodiment is shown. In the configuration shown in the first embodiment, the cover 102 is rotated about the pin shaft 102a, and can be removed from the standing posture substantially perpendicular to the main case 101 . On the other hand, in this second embodiment, the structure is a structure in which the cover 102 is lifted up vertically and removed from the state where the main case 101 is blocked. Thus, the main box 101 and the sub-box 103 are stacked vertically, the cover 102 is positioned on the main box 101 by the position pin 101d, and the cover body does not move when the sub-box 103 is moved. Therefore, in this second embodiment, when the paper feeding cassette 100 is taken out from the printer main body 1, the cover 102 can be easily detached from the main cassette 101, and the work when replenishing the main cassette 101 with paper S1 can be improved. ...

no. 3 Embodiment approach

[0063] the following, Figure 15 ~ Figure 18 3rd embodiment is shown. In addition, the same code|symbol is attached|subjected to the same or common member as the member shown in 1st, 2nd embodiment, and the description of the overlapping part is abbreviate|omitted.

[0064] Such as Figure 15 As shown, the paper discharge tray 200 for stacking the paper S discharged after being printed in the printer main body 1 is arranged directly above the above-mentioned paper feeding cassette 100 . A paper discharge panel 199 a is provided, and the paper discharge panel 199 a also serves as a partition between the lower paper feeding cassette 100 and constitutes the paper discharge tray 200 . The paper discharge panel 199a is integrally formed, is provided on the frame base 202 of the printer main body 1, and is used for stacking the discharged paper S.

[0065] Figure 16 Indicates the paper feed path (paper transport path) during printing. The components and devices for picking up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com