Heat exchanger set supporting piece, stuffing unit and closed type heat exchange tower

A technology for heat exchangers and heat exchange towers, which is applied in the direction of heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as ring-shaped stoppers falling off, and achieve simplified structure, good stability, and reduced Effect of number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

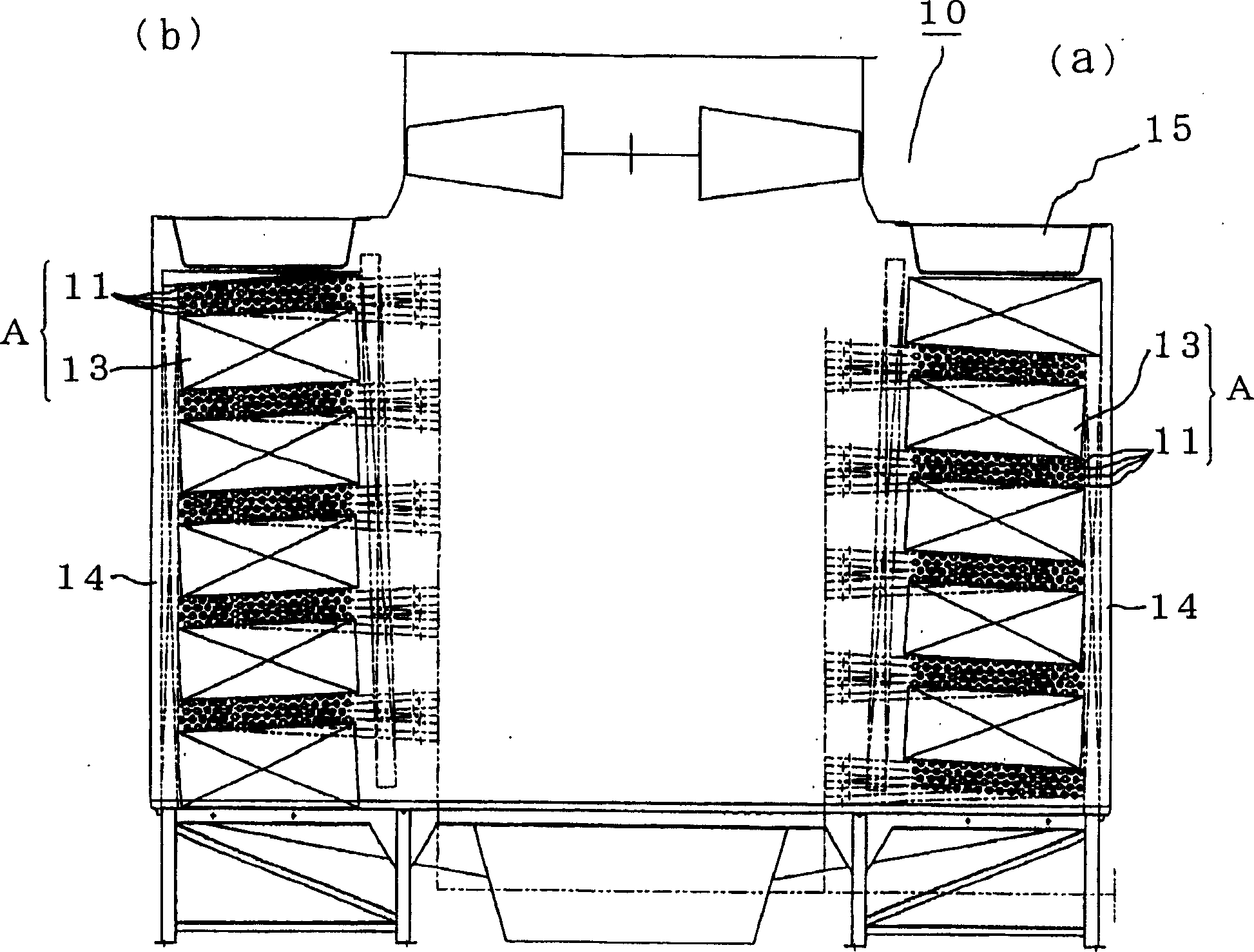

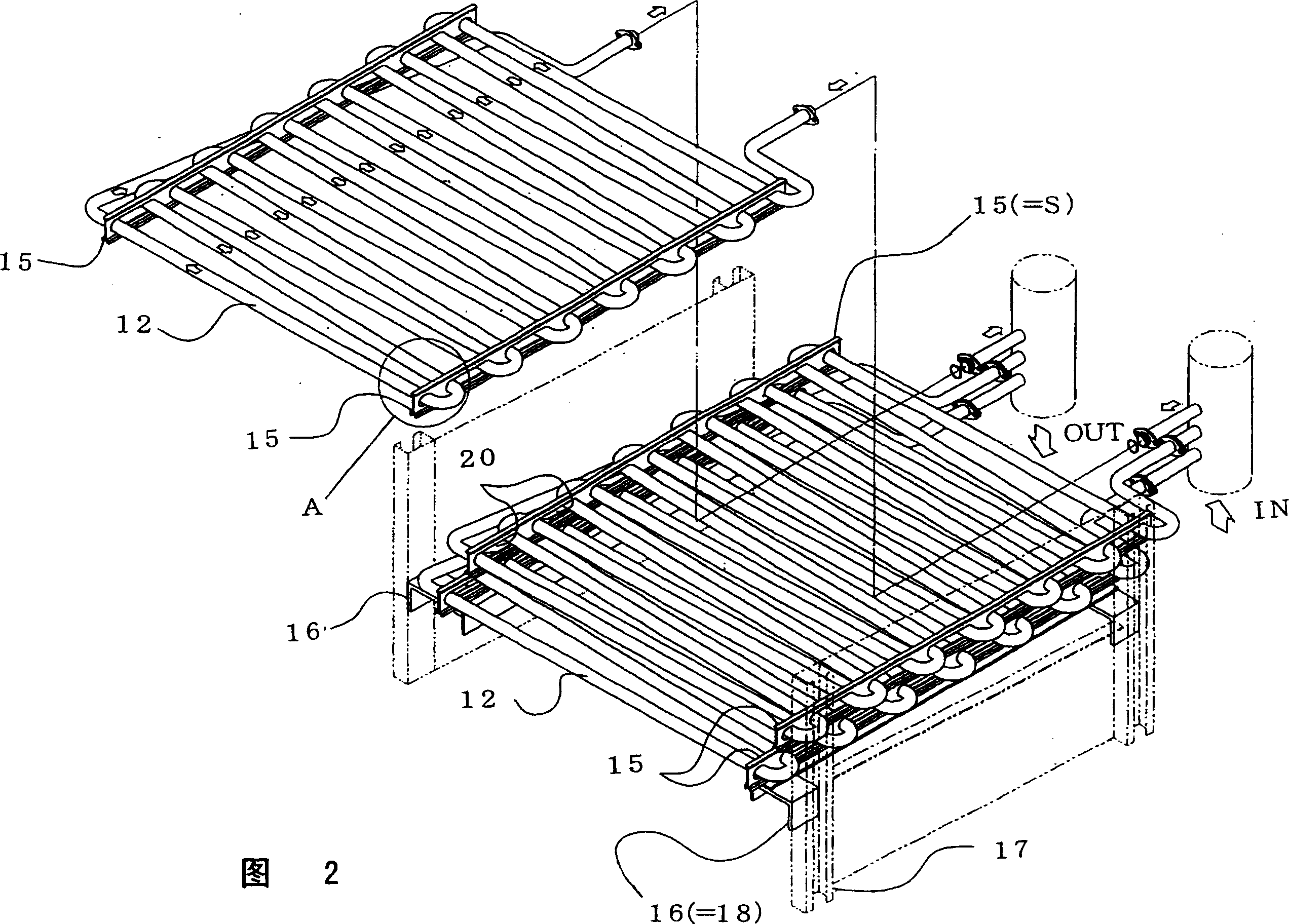

[0036] This embodiment is a representative embodiment of the heat exchanger stack support described in claims 1, 2, and 3, the packing unit described in claims 4, 5, and 6, and the heat exchange tower described in claim 8.

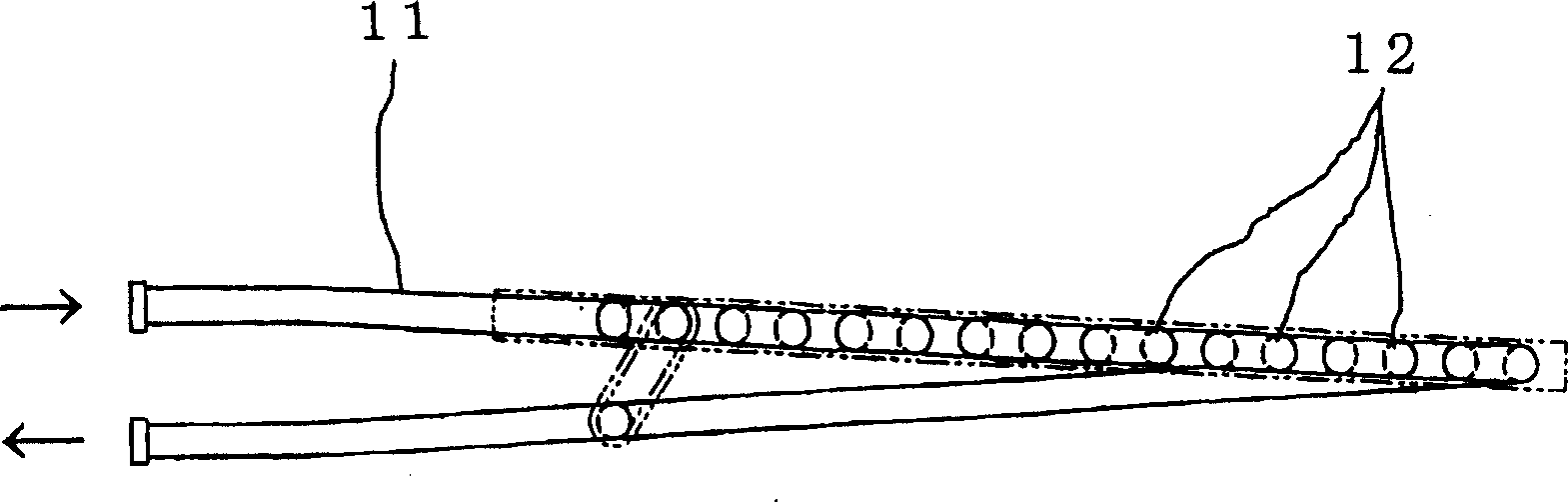

[0037] exist figure 1 (a), Figure 2, image 3 , Figure 4 , Figure 5Among them, the heat exchange tower 10 is filled with filler units A layered up and down in its frame. The filler unit A includes a closed heat exchanger 11 and a corrugated-plate-shaped filler 13 made of synthetic resin, and a plurality of fillers 13 are arranged side by side at intervals in the width direction of the external air inlet 14 . The plurality of straight pipe portions in each of the aforementioned hermetic heat exchangers 11 are parallel to each other, and are arranged substantially in parallel in the width direction of the external air inlet 14 .

[0038] The spray water sprayed on the packing unit A is directly contacted with the external air flow, and the spray water ...

Embodiment approach 2

[0059] Structures and functions different from Embodiment 1 are as follows.

[0060] exist figure 1 (b) In the present embodiment shown on one side, each filler unit A has a multi-layer closed heat exchanger 11 on the top and a filler 13 on the bottom. On the straight pipe part 12 of the multi-layer closed heat exchanger 11 in the packing unit A of the upper layer, all the spreading water is in contact with a straight pipe part of a certain layer of the upper and lower layers at least once, in the case of 4 layers shown in the figure , in contact with at least two layers, in fact at least three times with the straight pipe portion 12, and then flow to the filling member 13 below, under the direct contact with the external air flow accompanied by the flow, and the effect of latent heat generated by evaporation Next, the spreading water is cooled.

[0061] This action is repeated in each layer of filler unit A.

[0062] The spreading water is made to flow onto the filler 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com