Heat radiator, auxiliary jig and heat radiator manufacturing method

A technology of heat dissipation device and manufacturing method, which is applied in cooling/ventilation/heating transformation, instrumentation, electrical digital data processing, etc., and can solve problems such as reduced heat dissipation efficiency, poor fin uniformity, and poor parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

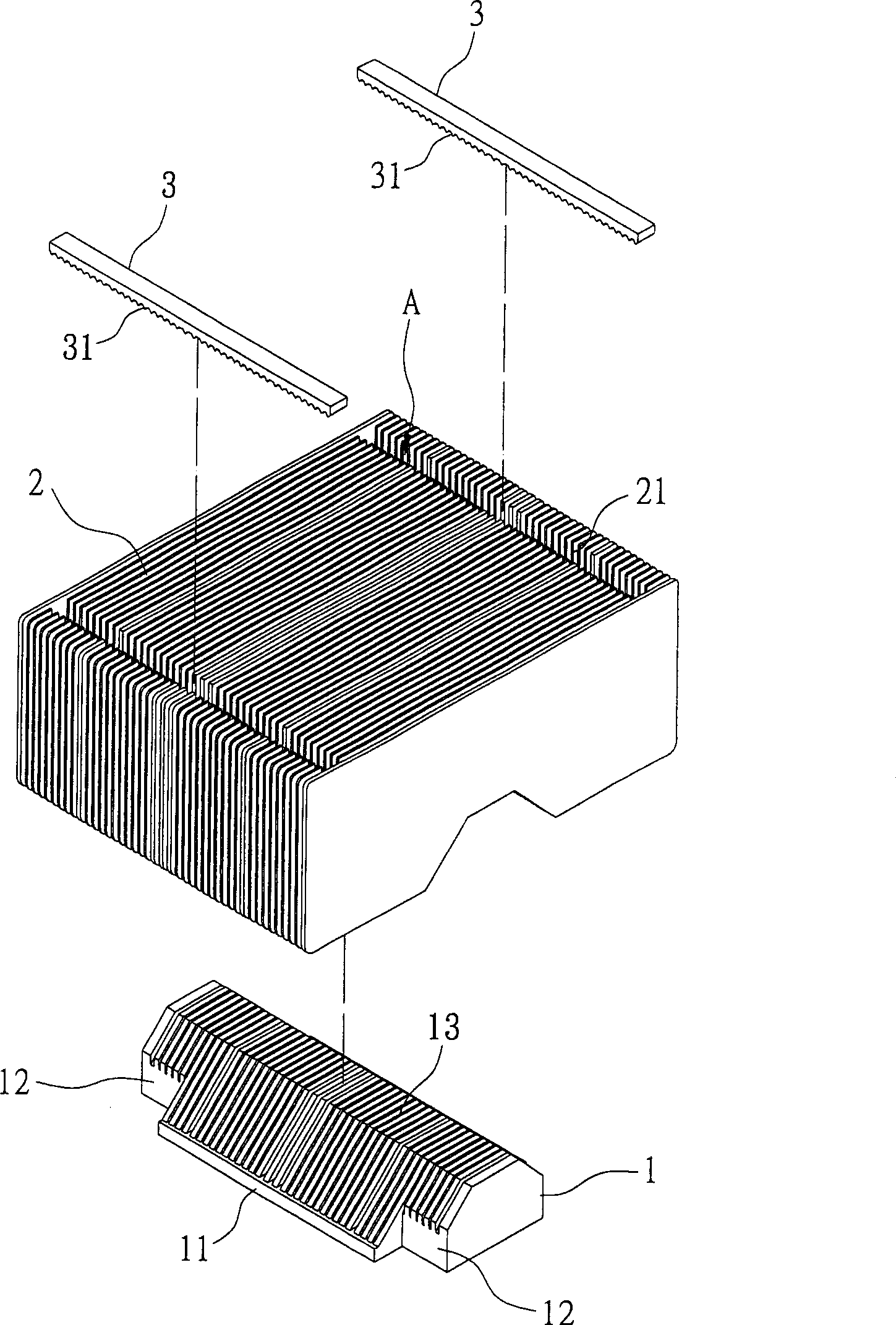

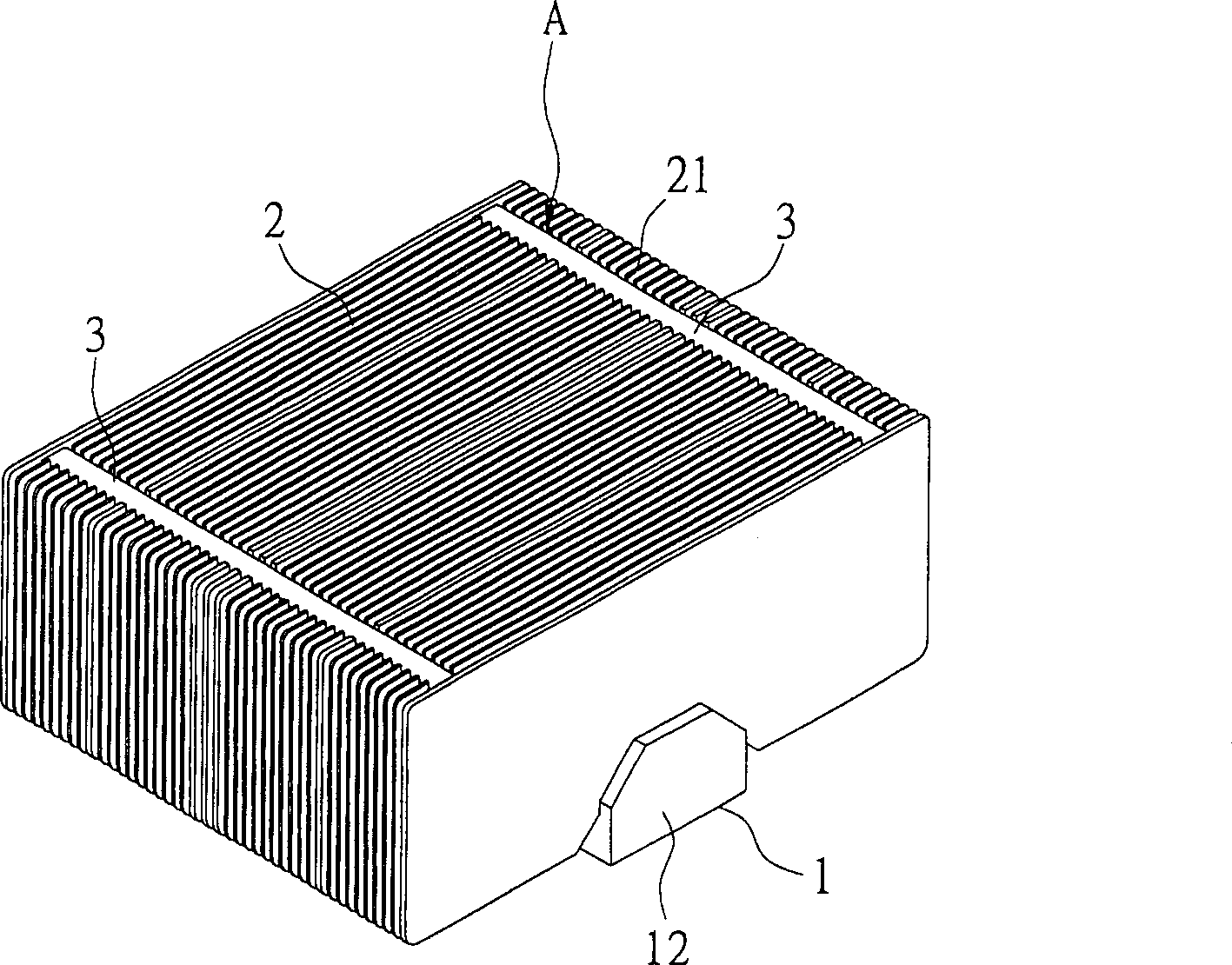

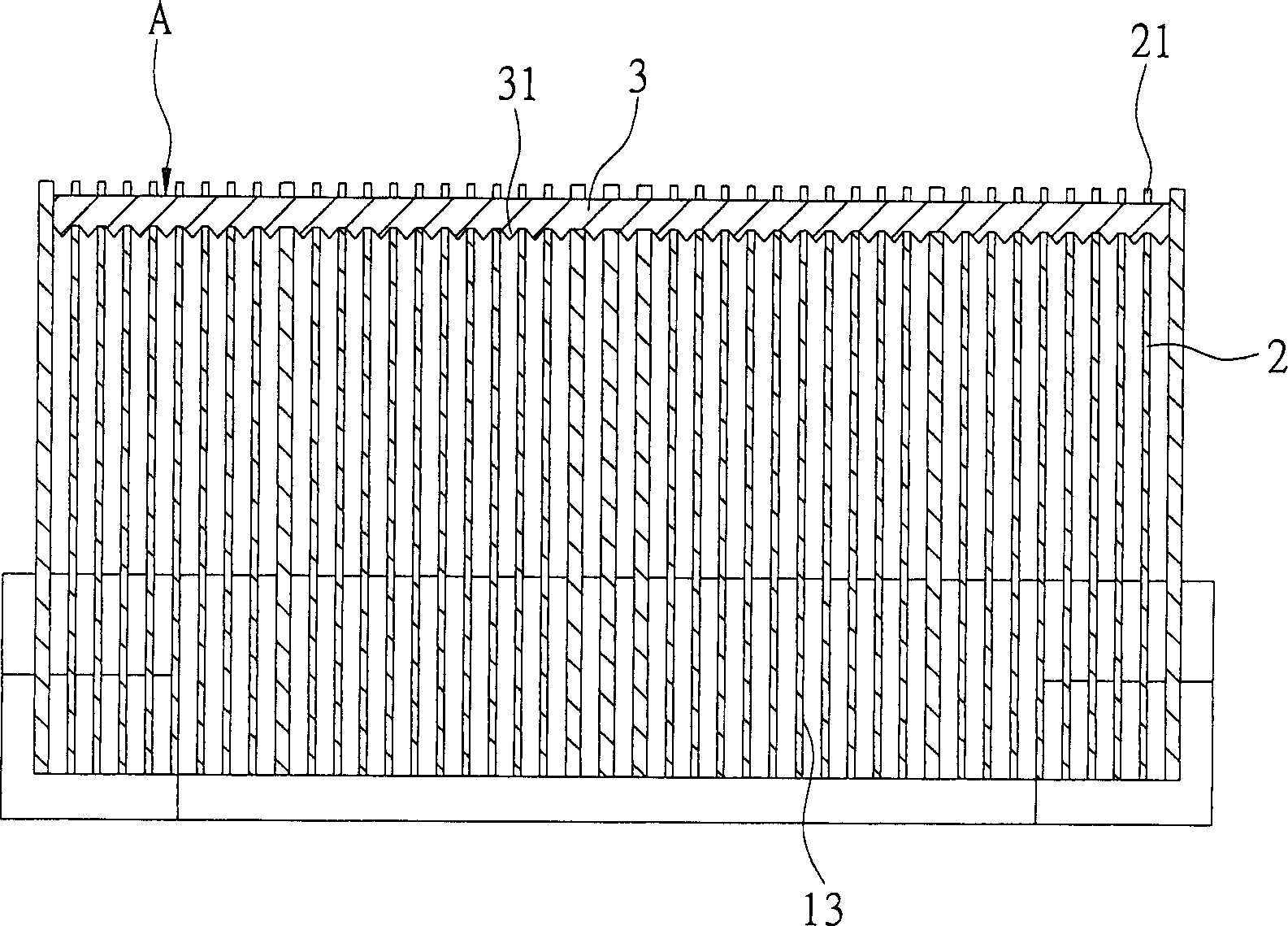

[0019] see Figure 1 to Figure 3 , the present invention is to provide a heat sink that can produce better parallelism, which includes a base 1, a plurality of fins 2 and at least one support device 3, wherein the base 1 is made of copper or aluminum and other thermal conductivity It is made of good metal material. In this embodiment, the base 1 includes a central section 11 and wing sections 12 respectively extending from two corresponding sides of the central section 11 . The base 1 is provided with a plurality of parallel grooves 13, and the plurality of grooves 13 are equidistantly arranged on the central section 11 and the wing section 12, and the top edge and two ends of each groove 13 are open. shape, which is convenient for assembling the plurality of fins 2 described above.

[0020] The plurality of fins 2 are sheets, and the plurality of fins 2 are made of metal materials with good thermal conductivity such as copper or aluminum, and the top edges of the plurality o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap