Weld structure having excellent brittle crack propagation resistance and method of welding the weld structure

A technology of brittle crack propagation and welding method, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that brittle cracks do not transfer to the base material, and achieve the effect of preventing the propagation of brittle cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

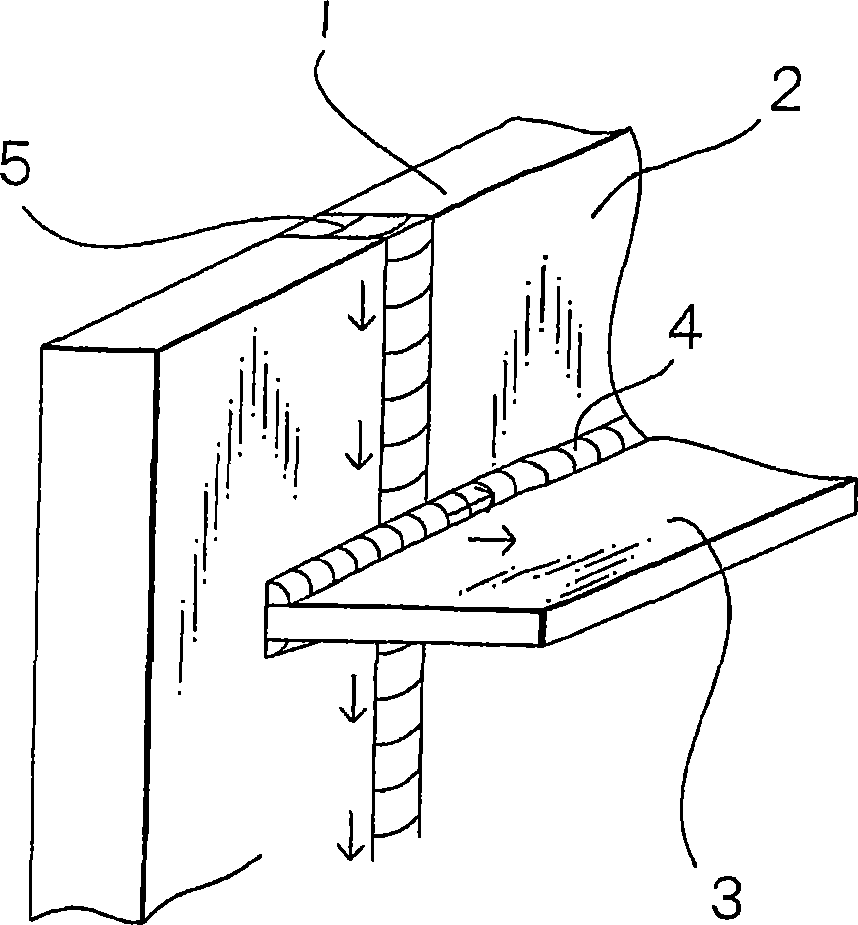

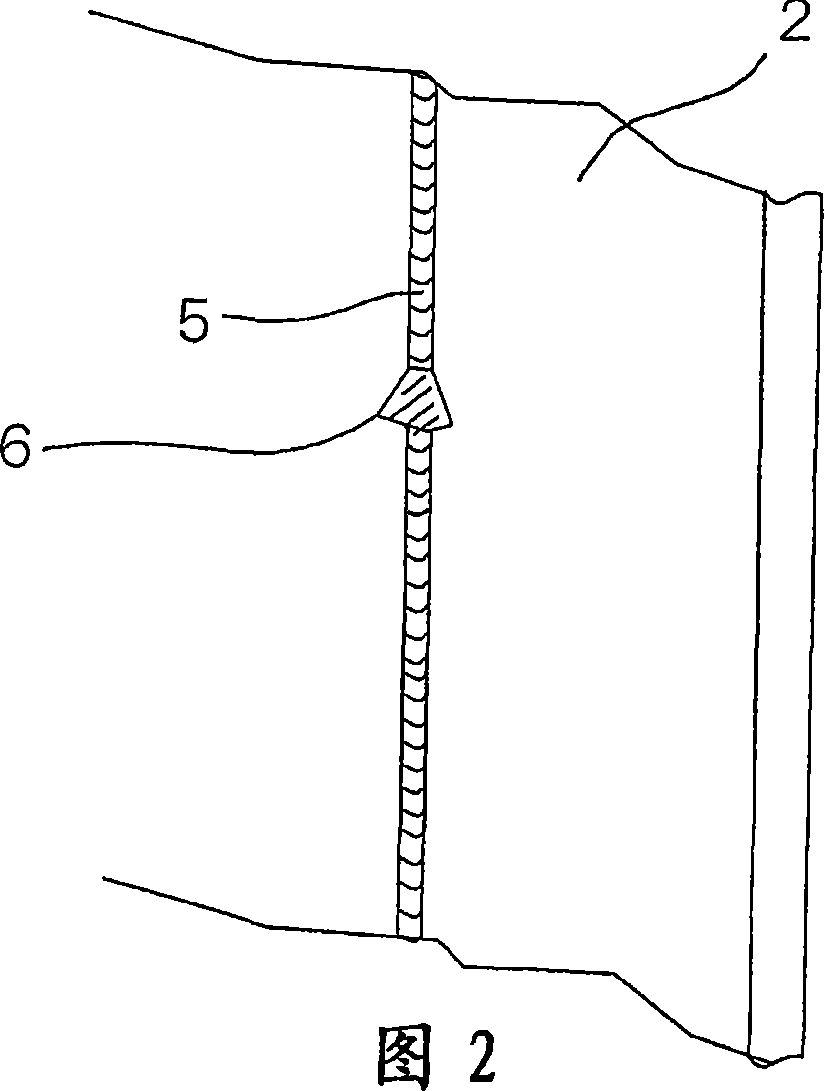

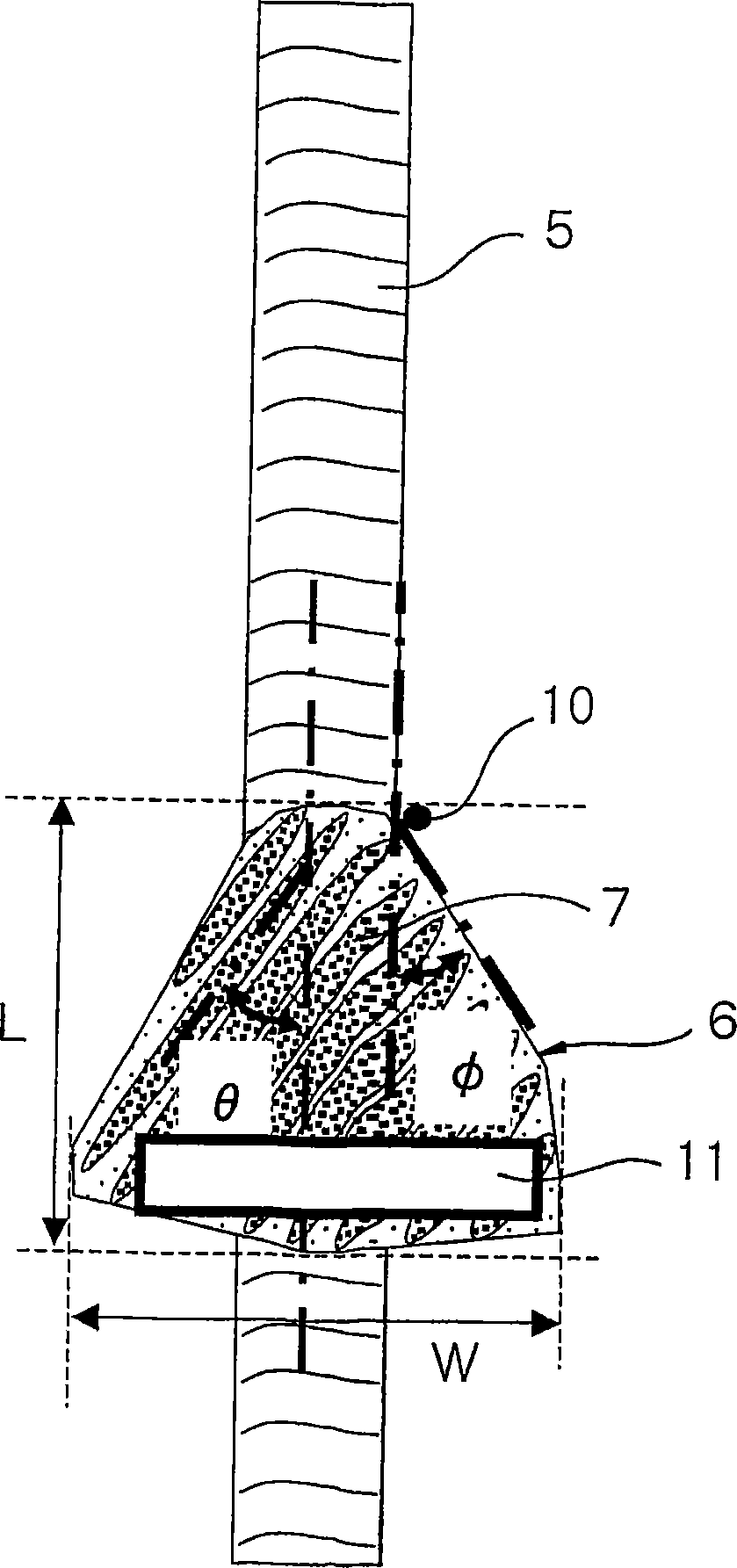

[0033] The best mode for carrying out the present invention will be described in detail with reference to FIGS. 2 to 4 .

[0034] Fig. 2 is a view showing a butt welded joint of a steel plate to which the welding method of the present invention is applied. In Figure 2, 2 represents the butt welding joint, 5 represents the butt welding area, and 6 represents the repair welding area.

[0035] The repair welding zone of the present invention is characterized in that, in the butt welded joint 2 (the heat-affected zone of the butt weld zone 5 and the steel plate 1) that has the possibility of brittle crack propagation as shown in FIG. In the region, a part of the butt welding joint 2 (the heat-affected zone of the welding region 5 and the steel plate 1) in the region is removed by gouging or machining, and then the part is repaired by welding with a welding material with excellent toughness, thereby The repair welding forms a repair welding zone 6 having a toughness higher than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com