Sheet member with frame body

A frame body, plate technology, applied in vehicle parts, engine components, engine sealing, etc., can solve problems such as improper application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

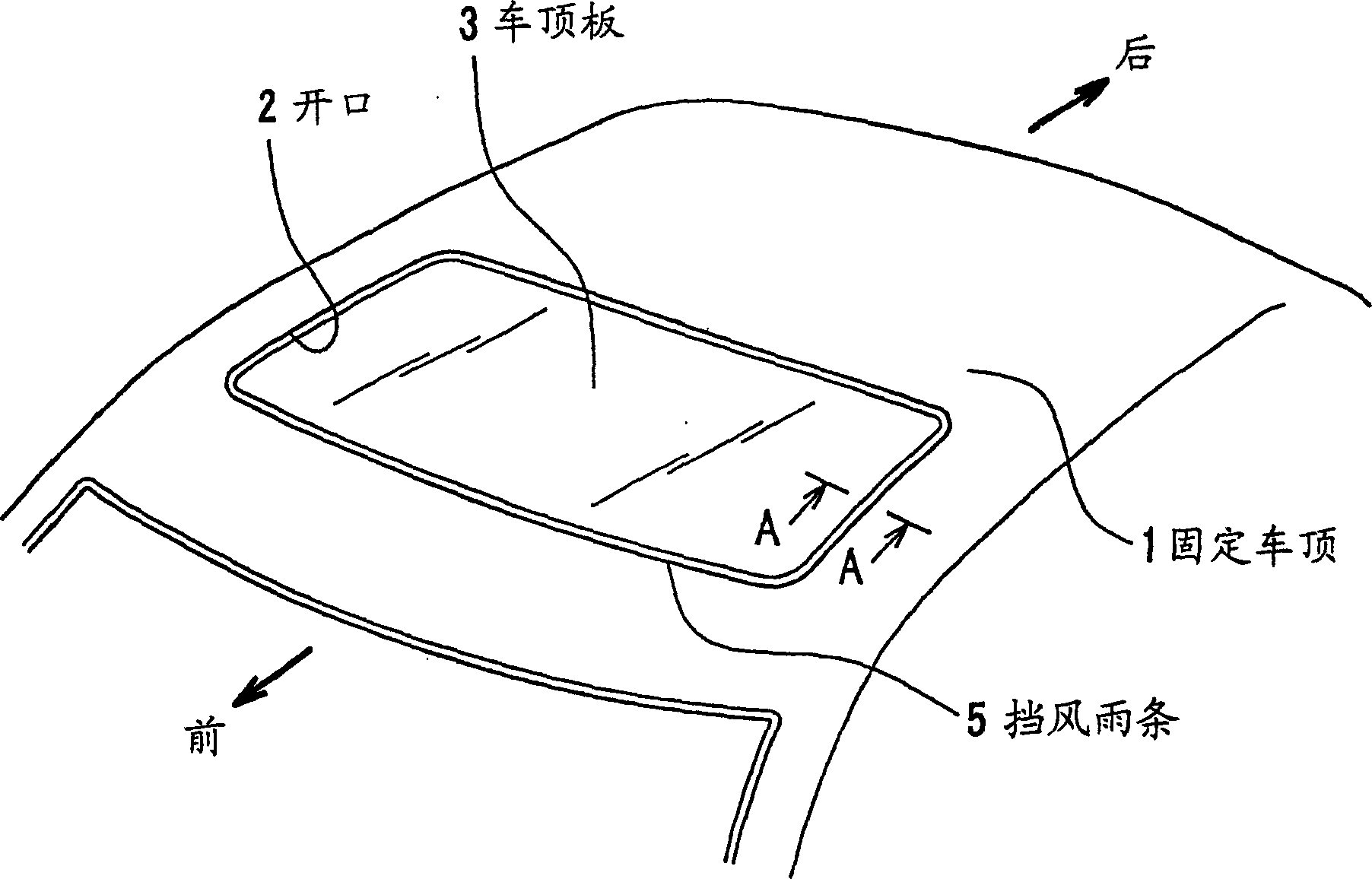

[0021] The following describes a case where a panel is assumed to be a roof panel in a vehicle sunroof apparatus. figure 1 is an external perspective view of a sunroof device, which includes a roof panel 3 that closes a rectangular opening 2 formed in a fixed roof when closed, and whose rear end slopes upward or downward when opened, and rearward sports. In one embodiment of the invention, the roof panel 3 is made of glass.

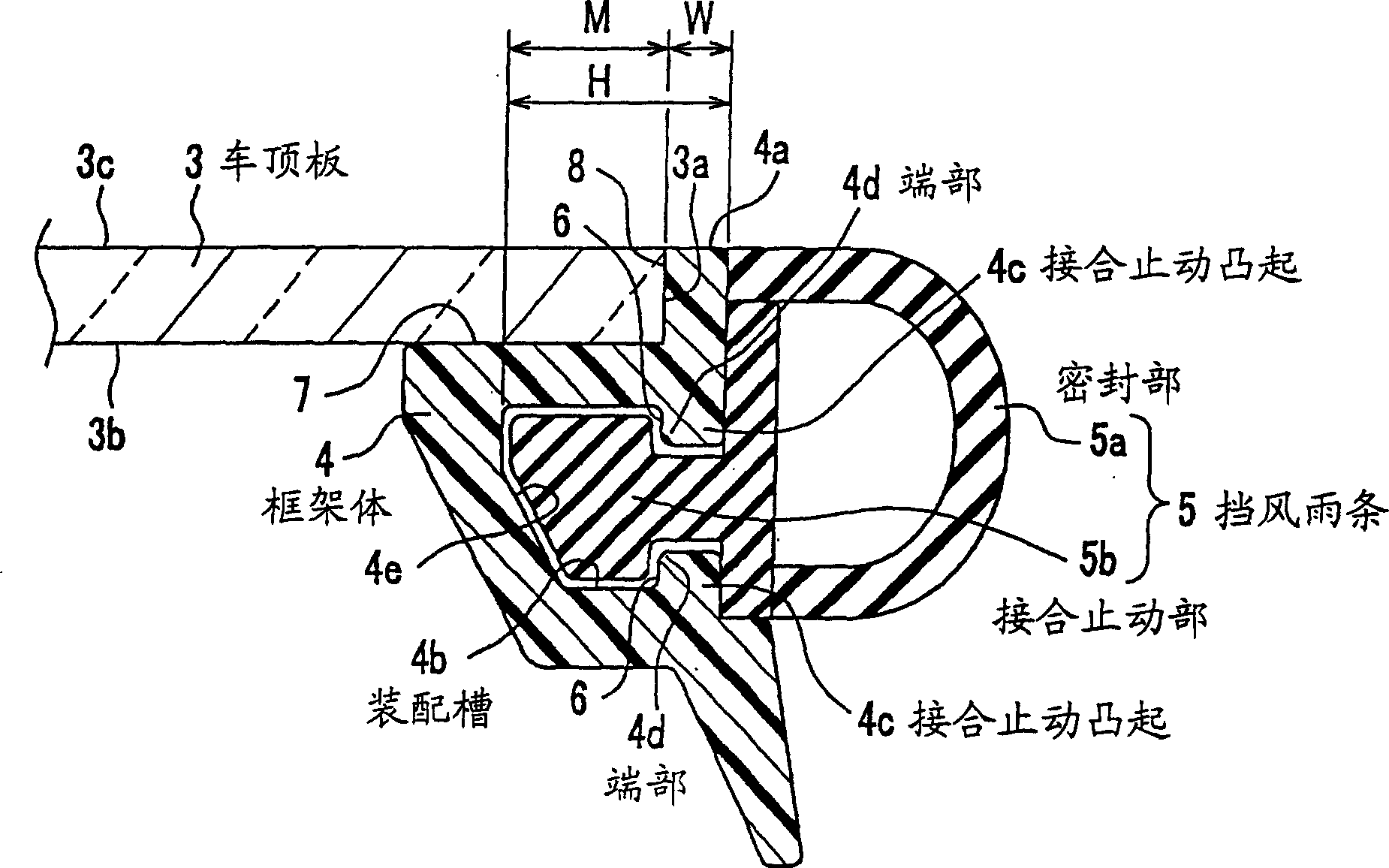

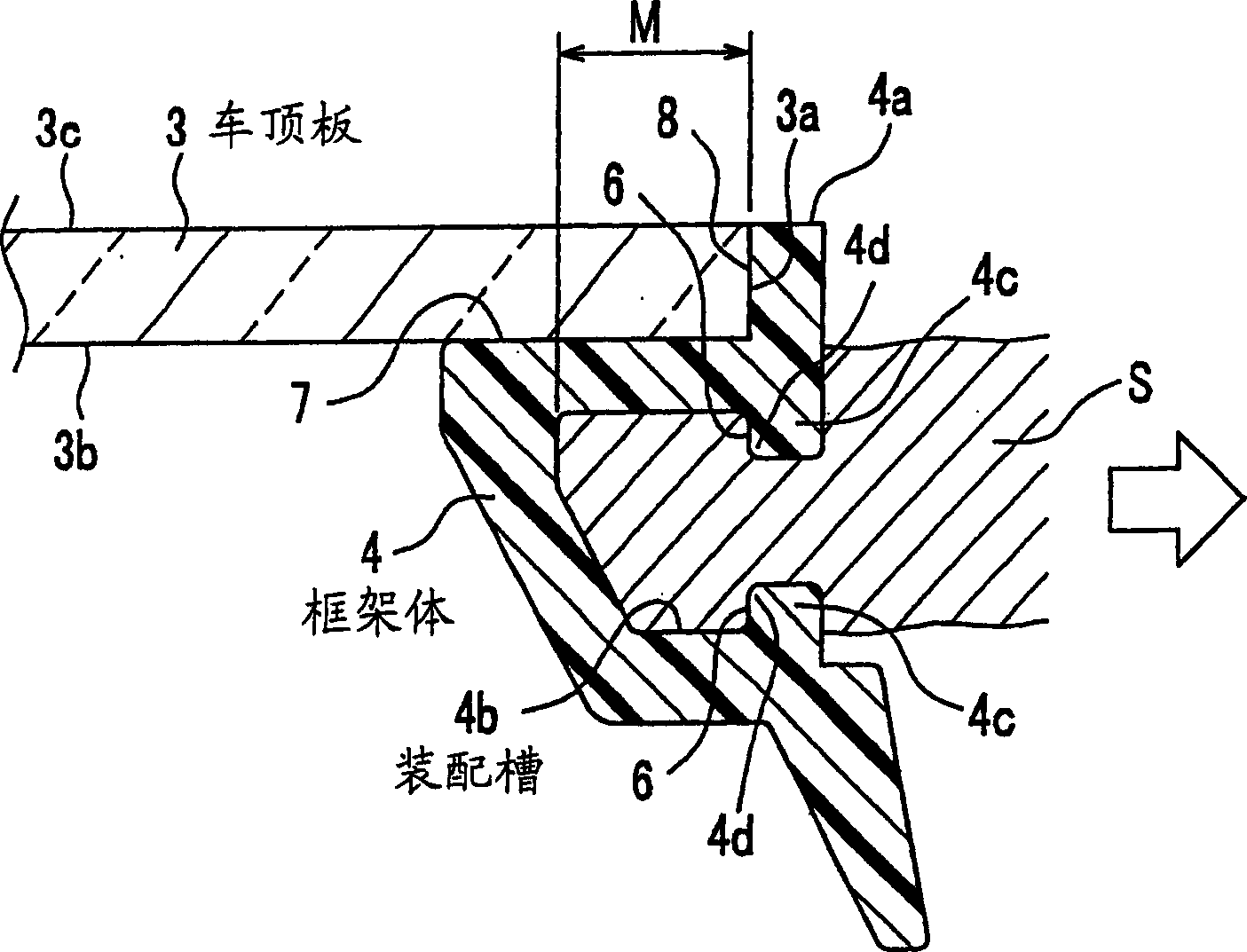

[0022] figure 2 yes figure 1 A-A sectional view in . On the edge of the roof panel 3 there is integrally provided a frame body 4 which is made of a resin material by injection molding on the base body. More precisely, the frame body 4 is attached to the entire surface of the end surface 3a of the roof panel 3 and around the bottom surface 3b of the panel 3, and the top surface 4a of the frame body 4 and the top surface 3c of the panel 3 are formed to be the same surface (aligned with each other). flat surface). Injection molding on a substrate incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com