Diffraction element and optical disk device

A diffractive element, center position technology, applied in beam guiding device, optical recording head, recording/reproducing with optical method, etc., can solve problems such as inability to prevent astigmatism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

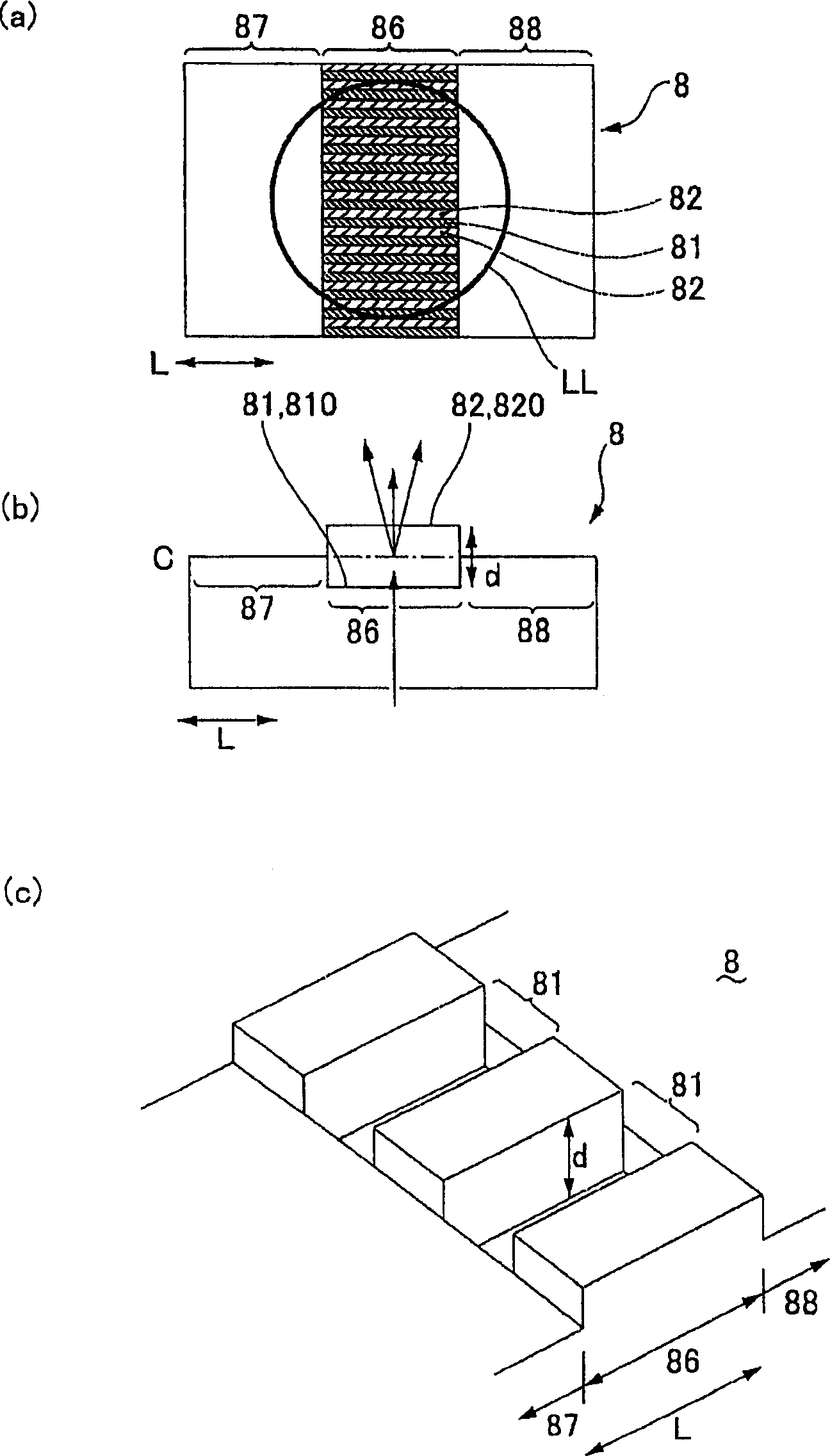

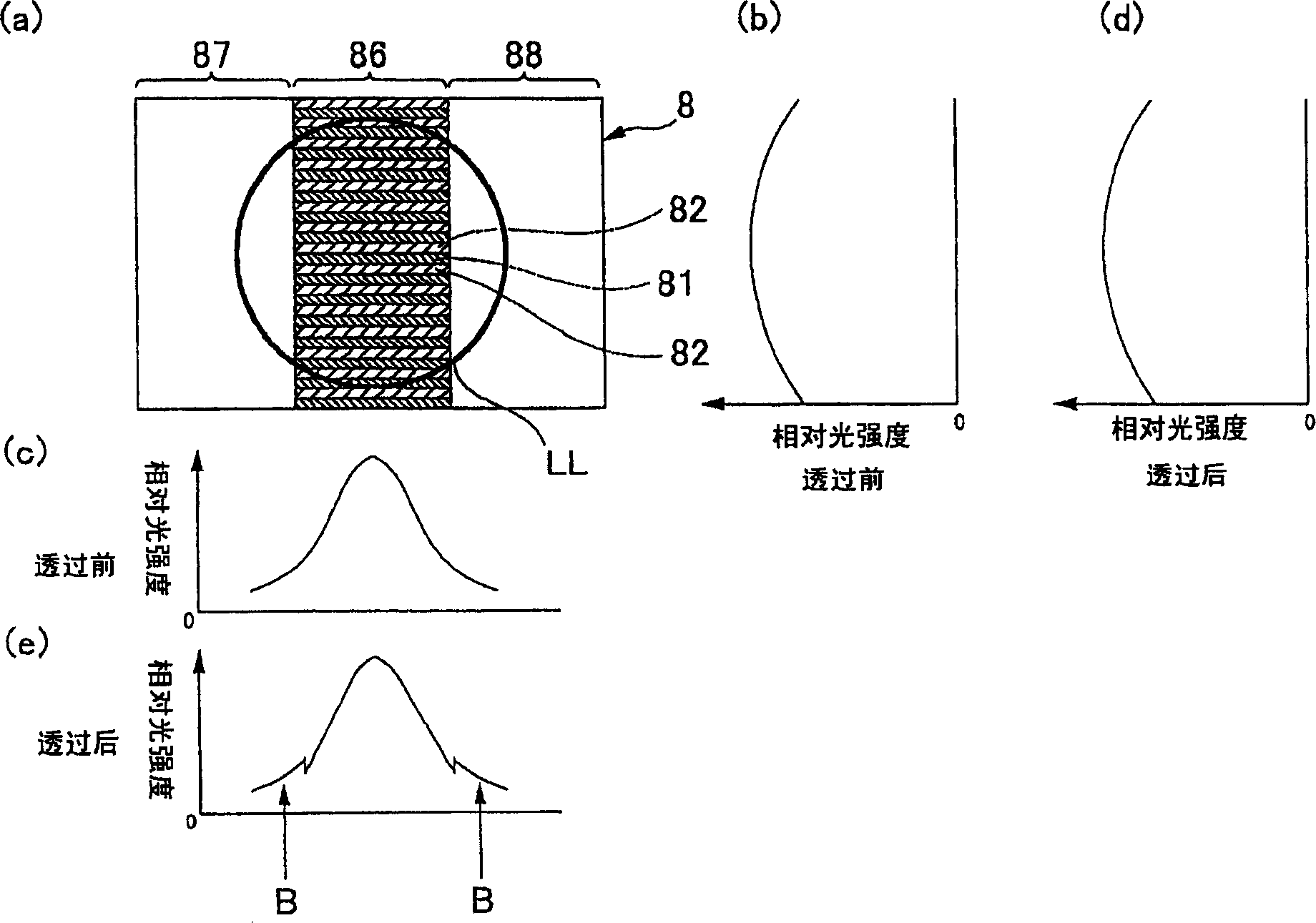

[0051] Figure 5 (a) and (b) are respectively a plan view of a diffraction element in another embodiment 1; and a cross-sectional view when the diffraction element is cut along the longitudinal direction of the groove portion. in addition, Figure 6 (a) and (b) are respectively a plan view of a diffraction element according to another embodiment 2; and a cross-sectional view when the diffraction element is cut along the longitudinal direction of the groove portion. In Embodiments 1 and 2 described below, since the basic configuration is the same as that of Embodiment 1, common parts are described with the same reference numerals.

[0052] Such as Figure 5 (a), (b) and Figure 6 As shown in (a) and (b), in the optical disc device 1 of the other embodiments 1 and 2, as in the above-mentioned embodiment, a plurality of grooves and ridges are formed in the center of the diffraction element 8 and arranged alternately. The grid area 86 is formed, and the two sides of the grid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com