Computer device of color separation for bamboo strips automatically

A bamboo chip and color separation technology, which is applied in the field of automatic bamboo chip computer color separation equipment, can solve the problems of difficult to find skilled workers, high quality, human eye damage, etc., and achieve the effect of high degree of automation, high production efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

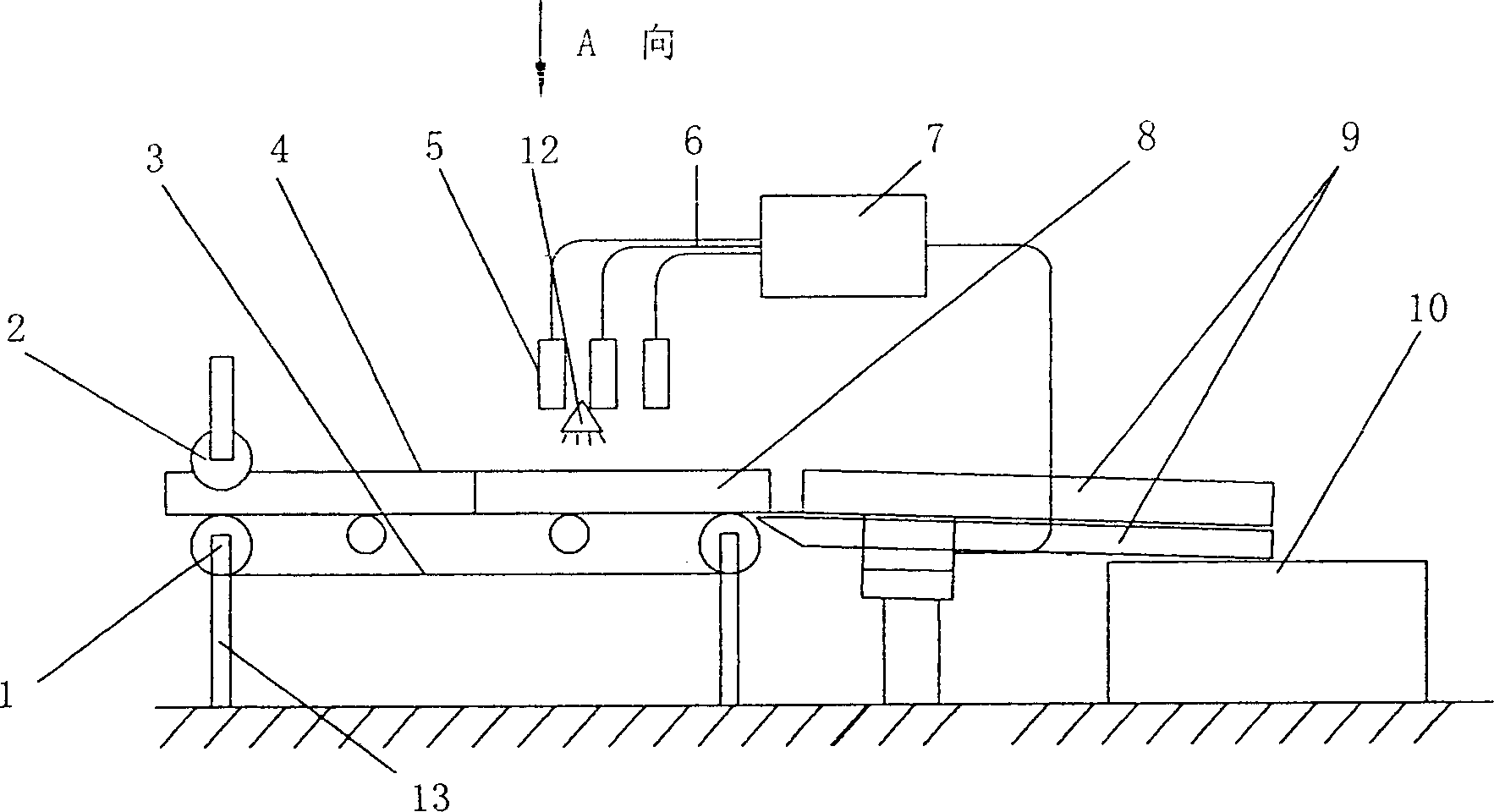

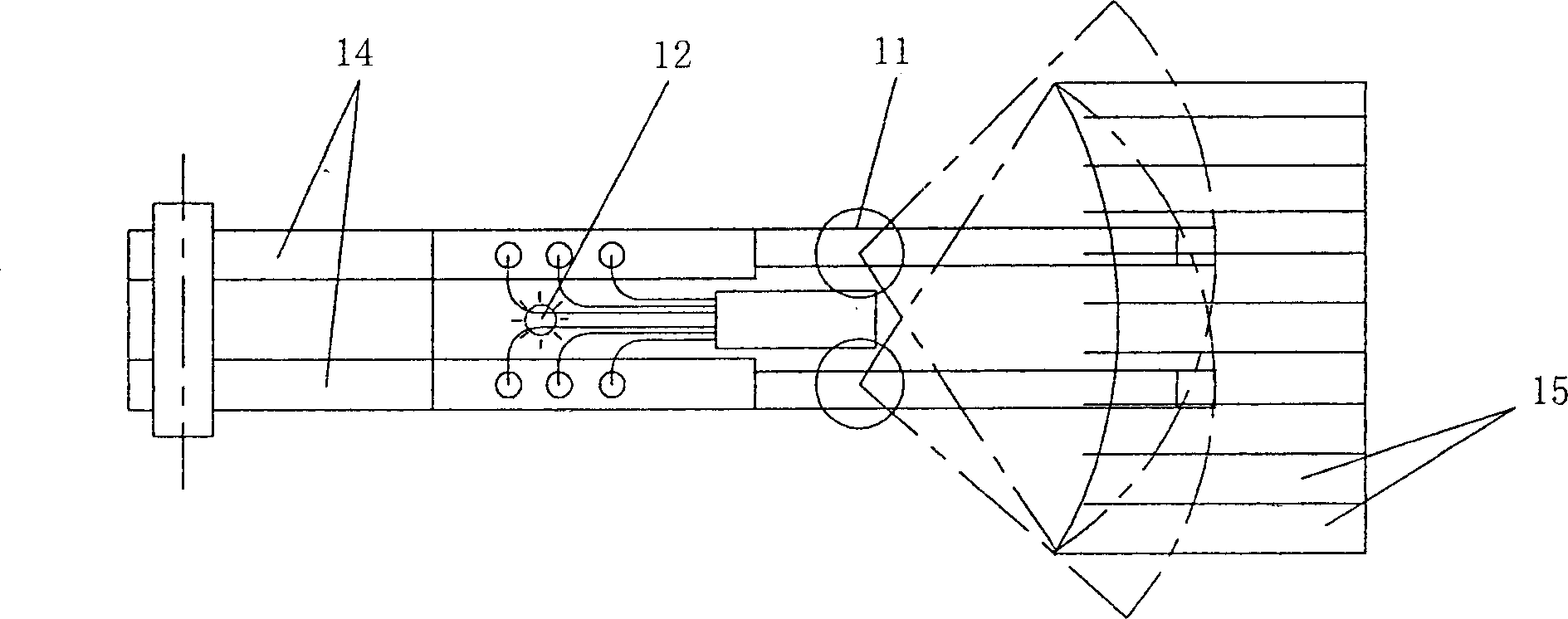

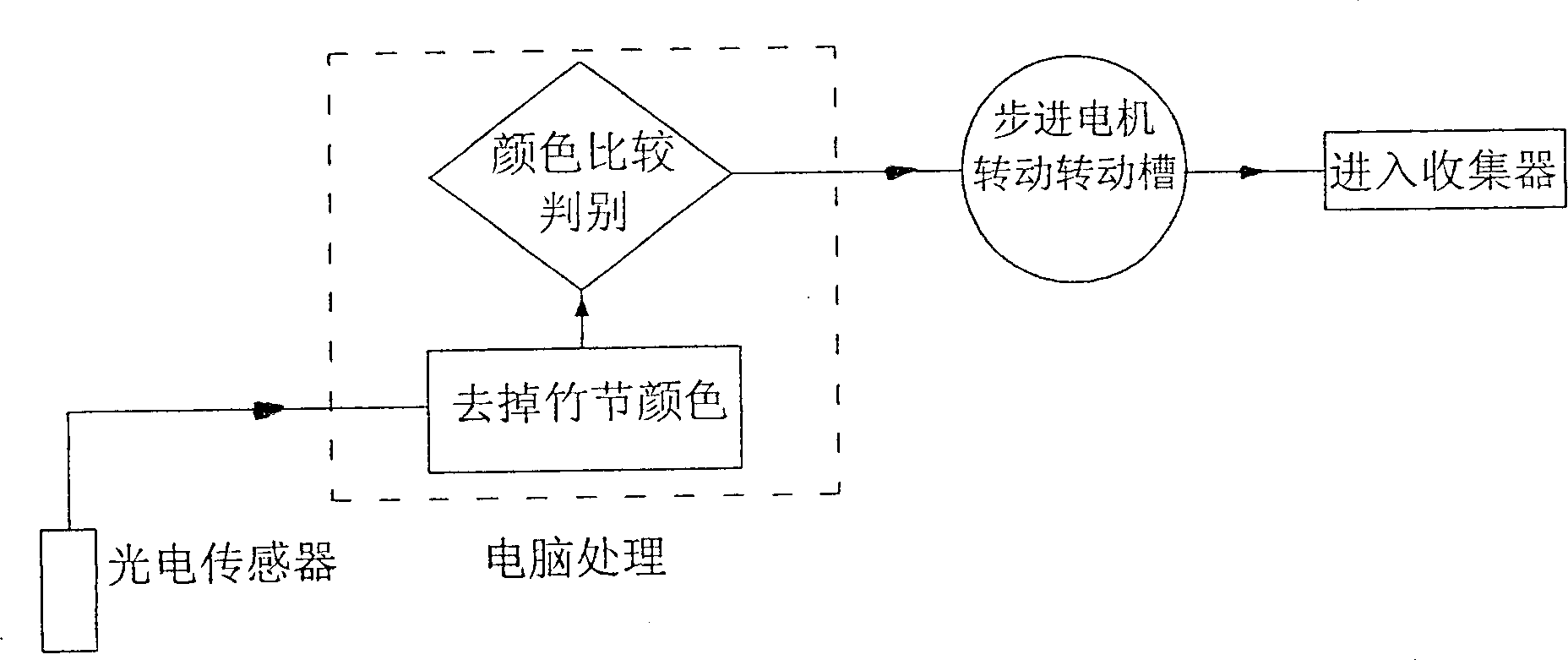

[0014] Such as figure 1 , figure 2 As shown, the present invention takes two color-separation sorting bamboo chip conveying grooves as an example: the conveying device comprising the main drive wheel 1 and the adjustable pinch wheel 2 is installed in two color-separating sorting bamboo chip conveying grooves 14 One end of one end forms two bamboo chip feeding passages, and two color separation sorting bamboo chip conveying grooves 14 near the main drive wheel 1 and the adjustable pinch wheel 2 side are two covered conveying grooves 4, and the other section Two color separation and sorting bamboo chip conveying grooves 14 are two uncovered conveying grooves 8, and two color separation and sorting bamboo chip conveying grooves 14 are provided with one group of bamboo chip conveyor belts 3 driven by the main drive wheel 1 below, and 13 are Support, the outlet ends of two coverless conveying grooves 8 are connected with two rotating grooves 9 with an inclination driven by respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com