Ultrasound electrical motor, and driving method

A technology of ultrasonic motor and driving method, which is applied in the directions of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. problem, to achieve the effect of less high-order harmonics, less harmonic interference, and saving switching devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

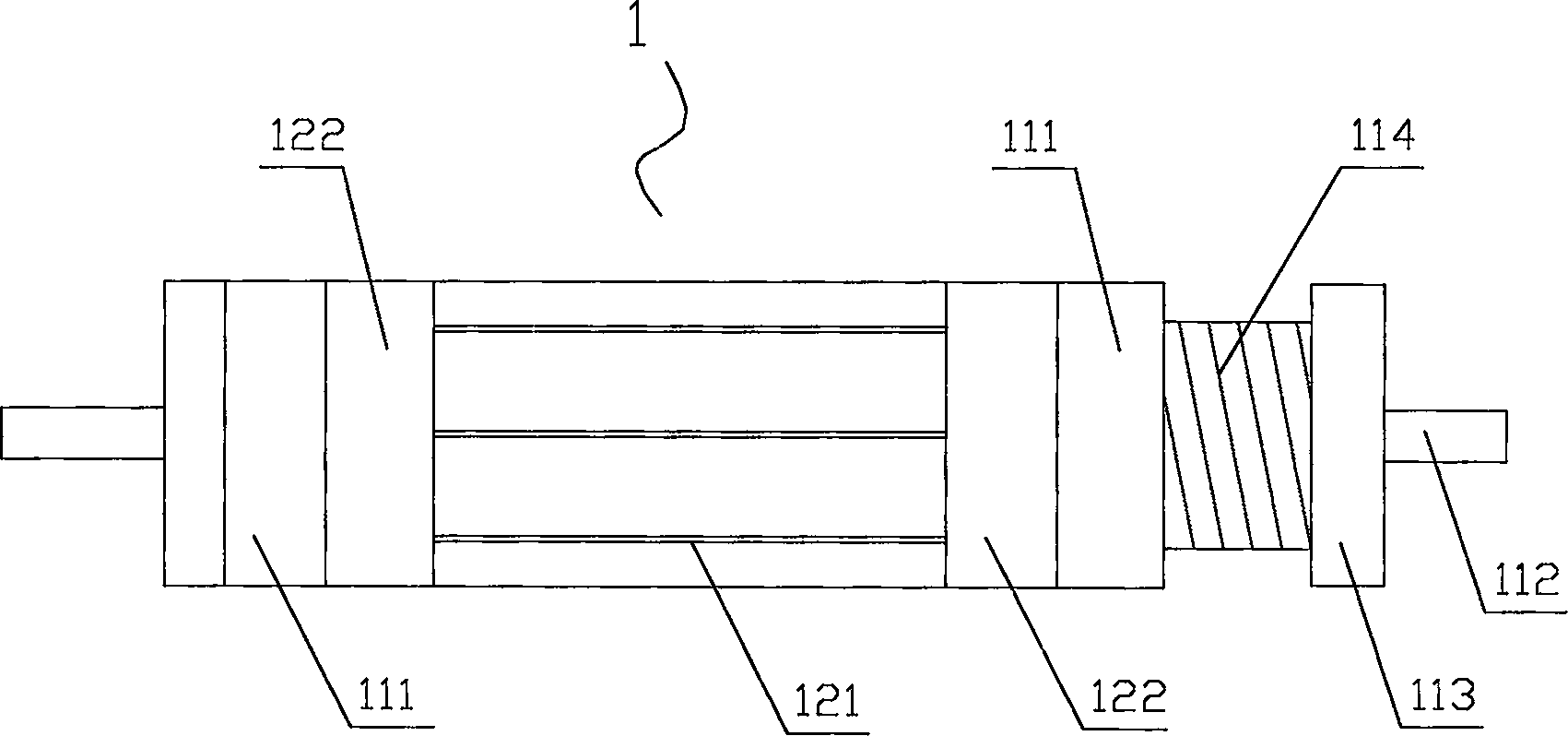

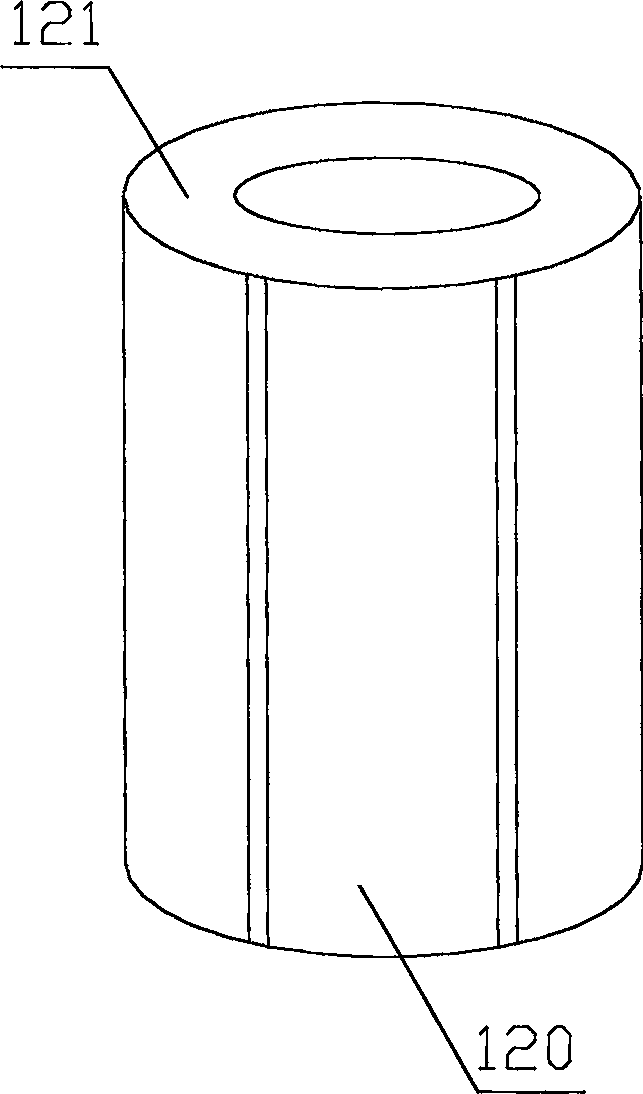

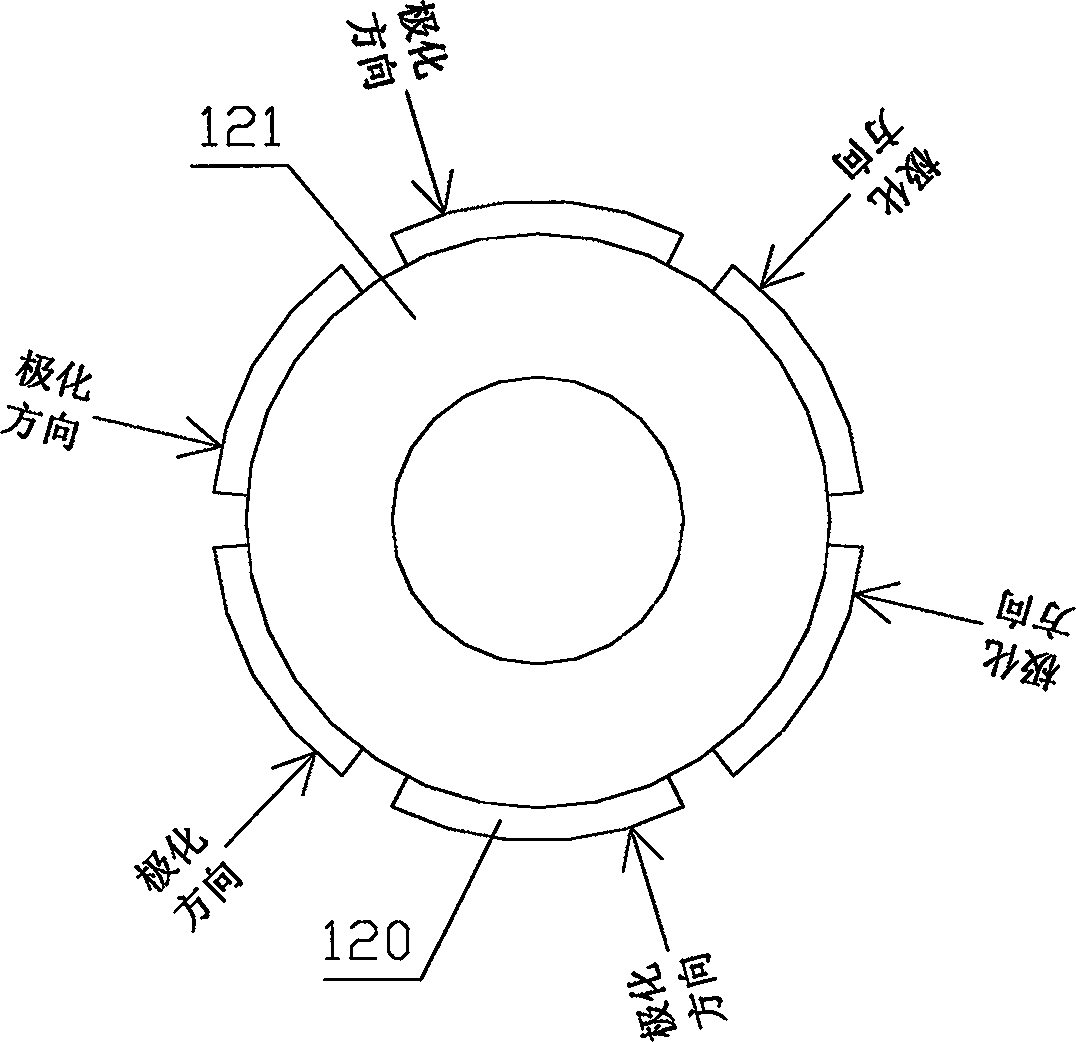

[0035] according to figure 1 As shown, the present invention includes a motor body 1, and the motor body 1 includes a rotor and a stator, such as figure 1 and figure 2 As shown, the stator includes a cylindrical piezoelectric ceramic tube 121, an end pressure piece 122 and a piezoelectric element 120, the piezoelectric ceramic tube 121 and the end pressure piece 122 are connected, and the piezoelectric element 120 is pasted outside the piezoelectric ceramic tube 121 On the surface, the rotor includes a rotating block 111, a rotating shaft 112, a nut 113 and a spring 114. The rotating shaft 112 passes through the stator. The two rotating blocks 111 are connected to the rotating shaft 112 and clamped on both sides of the stator. side, the inner side of which presses against the spring 114 , and the spring 114 is sleeved on the rotating shaft 112 .

[0036] Such as figure 2 and image 3 As shown, the piezoelectric element 120 is a piezoelectric ceramic sheet, and the number...

Embodiment 2

[0047] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is: in this embodiment, the piezoelectric ceramic tube 121 is a regular hexagonal prism type, which can be metal or non-metallic material, as for other parts of the structure, and related driving process and implementation The same or similar as described in Example 1, and will not be repeated here.

Embodiment 3

[0049] according to Figure 7 and Figure 8, the main difference between this embodiment and Embodiments 1 and 2 is: in this embodiment, the multi-phase power supply is a power supply with 5-phase phase difference of 72°, and its five-phase terminals are respectively U, V, W, S, T , the number of piezoelectric elements 120 is twice the number of 5, that is, 10. As for other parts of the structure, and the relevant driving process is the same or similar to that described in Embodiment 1 or Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com