Intelligent control method capable of reducing higher harmonics for pumping unit

A high-order harmonic and intelligent control technology, applied in the direction of AC motor control, control system, harmonic reduction device, etc., can solve problems such as production reduction, damage to oil well equipment and power grid equipment, and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

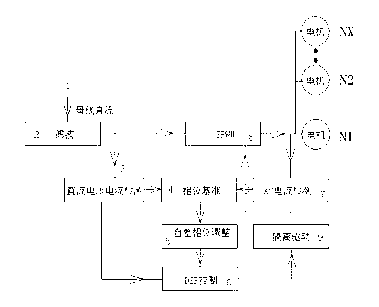

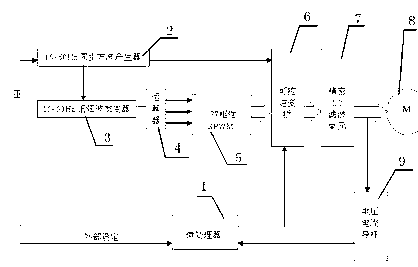

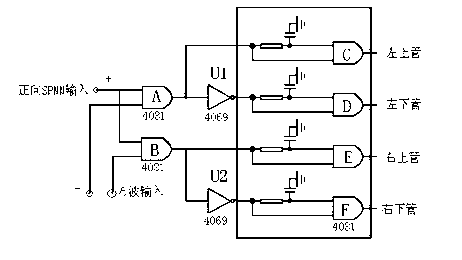

[0019] Such as figure 1 As shown, the intelligent control method for pumping units that can reduce high-order harmonics includes at least filter circuit 2, DC voltage and current detection circuit 3, phase reference circuit 4, self-difference phase adjustment circuit 5, DSP control circuit 6, AC current detection Circuit 7 and SPWM unit 8, bus DC 1 is divided into two circuits after passing through filter circuit 2, and one circuit is divided into distributed motors N1, N2, N3, N after passing through SPWM unit 8 X Electric connection; the other is to the DC voltage and current detection circuit 3, and the DC voltage and current detection circuit 3 is divided into two circuits after processing, one to the phase reference circuit 4, and the other to the DSP control circuit 6; the phase reference circuit 4 is connected to the AC current on the one hand The detection circuit 7 is electrically connected to receive the AC current signal of the motor drive circuit detected by the AC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com