Multifunctional numerical control machine

A CNC machine tool, multi-functional technology, applied in the direction of metal processing mechanical parts, clamping, support, etc., can solve the problems of inability to meet mass production, high production cost, high price, etc., to achieve a wide range of processing, high production efficiency, manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

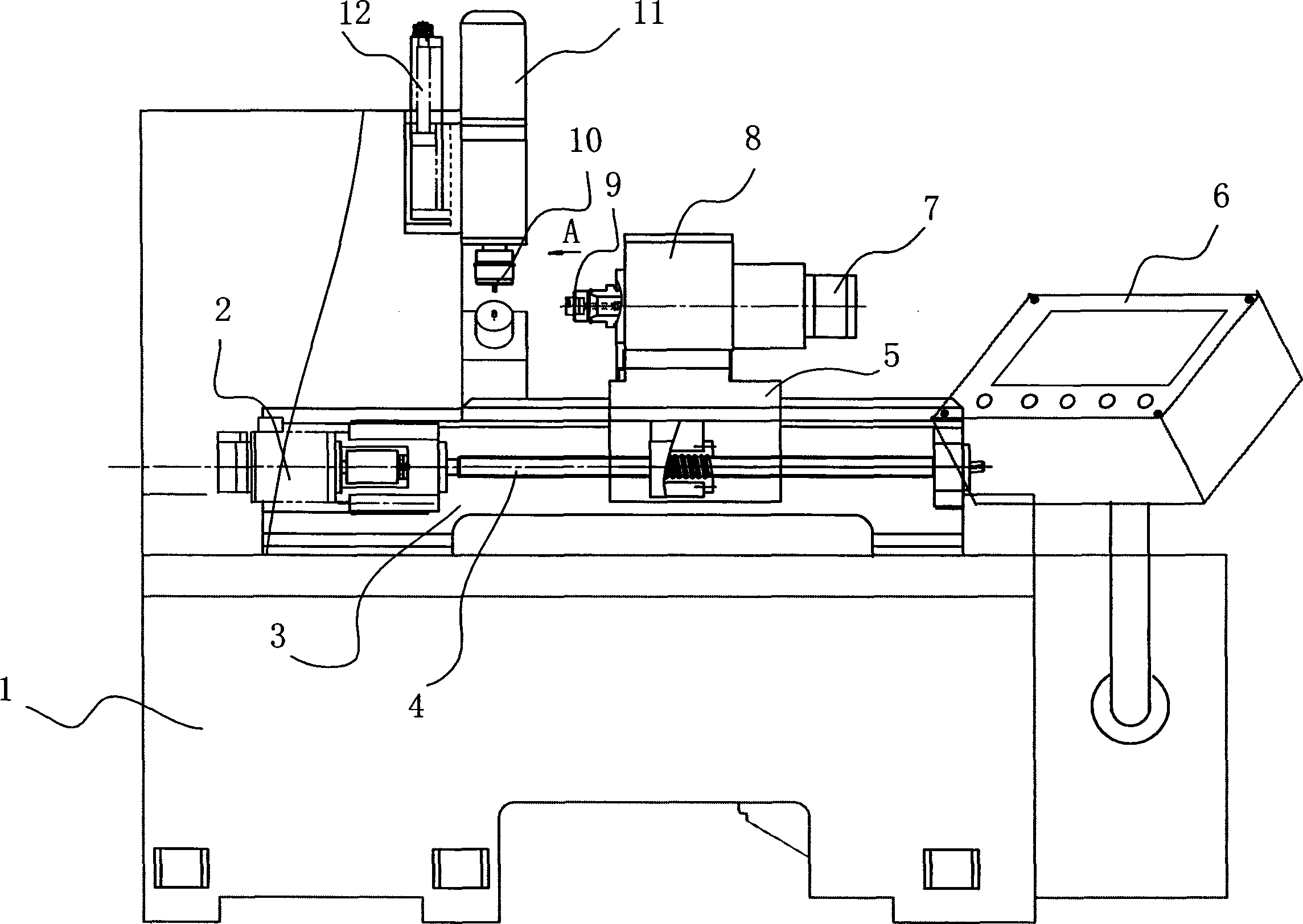

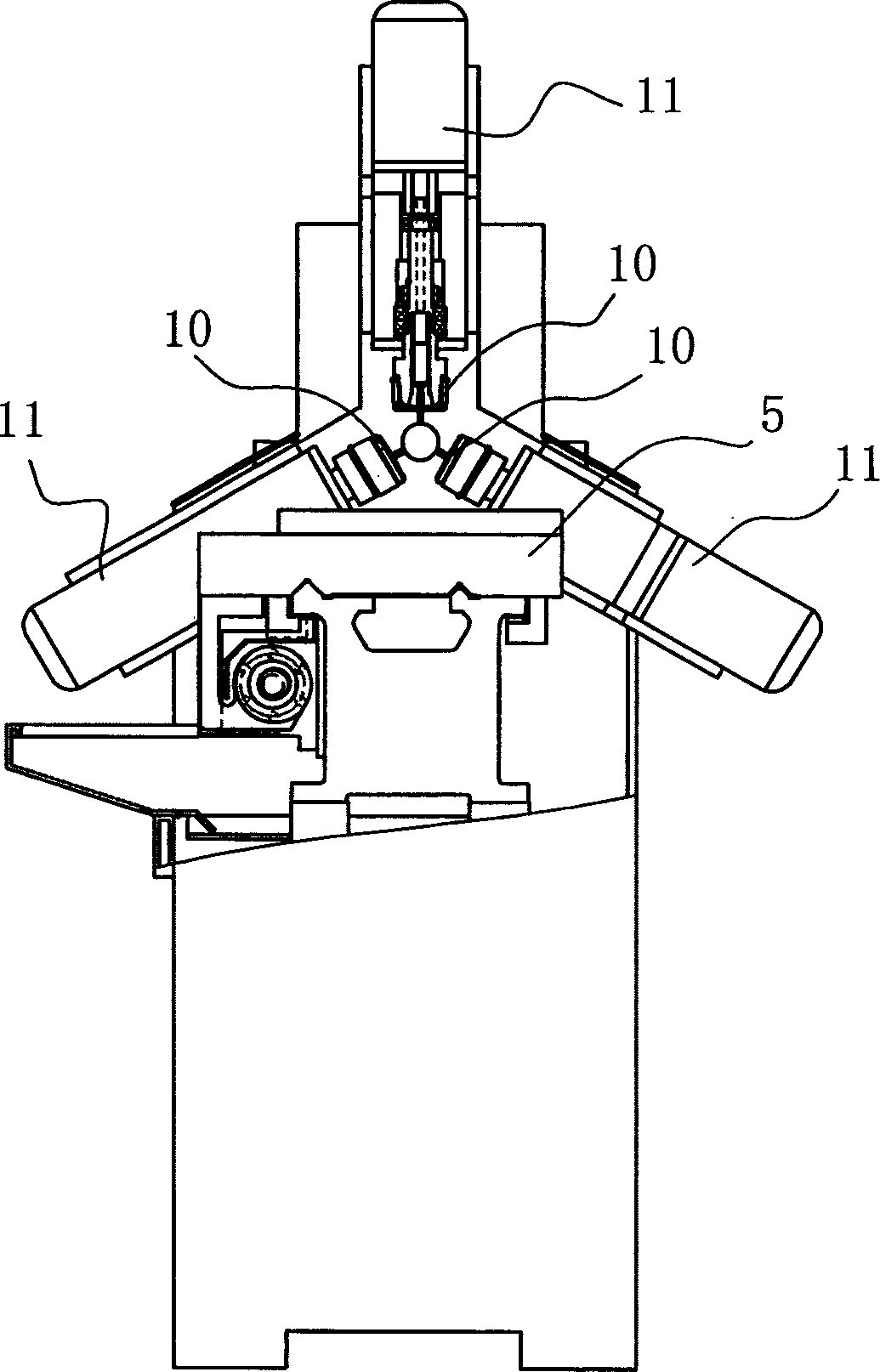

[0017] Figure 1-Figure 2 One embodiment of the multifunctional numerically controlled machine tool of the present invention is shown. It consists of a bed 3 with a bed leg 1 equipped with a carriage 5 that can slide along the guide rail. The carriage 5 is driven by a ball screw 4 installed on the bed. Or servo motor 2 drives. The lead screw pair is driven by the stepping or servo motor 2, and the lead screw 4 drives the carriage 5 through the bracket.

[0018] A reduction box 8 whose main shaft is consistent with the length direction of the guide rail is installed on the carriage 5, and a clamp part 9 for clamping the workpiece is installed on the main shaft of the reduction box (that is, the power output shaft). The clamp part 9 mainly adopts a collet, The collet is automatically clamped or loosened by the cylinder or oil cylinder 7. Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com